Control platform for automatic detection

An automatic detection and control platform technology, applied in the field of automation, can solve the problems of interfering with the use effect and quality of products, insufficient rack sensor feedback, poor visual perception, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

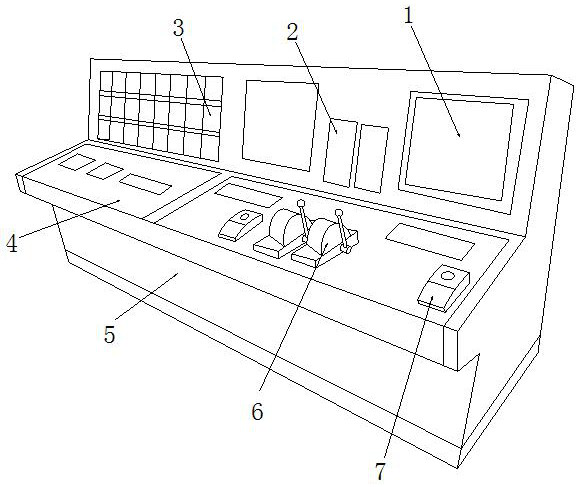

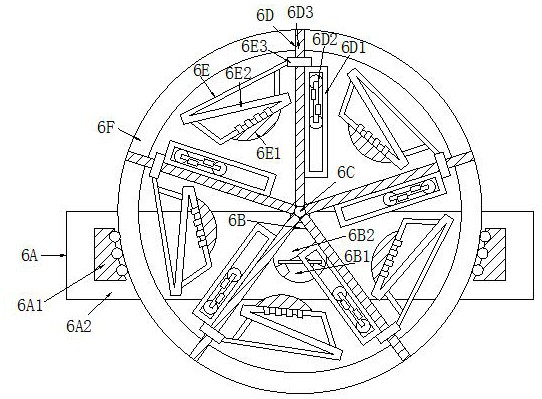

[0033] see Figure 1-Figure 6, the present invention provides a control platform for automatic detection, its structure includes: man-machine interface 1, data display table 2, voltage surface panel 3, industrial console 4, integrated control cabinet 5, angular distance relay wheel base 6, The start-stop button plate 7, the angular distance relay wheel seat 6 is installed on the top surface of the front end of the integrated control cabinet 5, the start-stop button plate 7 is provided with two and installed on the angular distance relay wheel seat 6 respectively On the left and right sides, the industrial console 4 and the integrated control cabinet 5 are closely integrated and are on the same horizontal plane. On the slope, the voltage surface board 3 is inserted into the interior of the integrated control cabinet 5, and the angular distance relay wheel seat 6 is provided with a clamp pad relay seat 6A, a pull button bottom wheel 6B, a shaft core rod 6C, and Heavy armature f...

Embodiment 2

[0040] see Figure 1-Figure 6 , the present invention provides a control platform for automatic detection, other aspects are the same as embodiment 1, the difference is:

[0041] see figure 2 , the spacer cap rib frame 6E is composed of a lining cap seat 6E1, a corner bracket frame 6E2, and a buckle collar 6E3. The lining cap seat 6E1 and the corner bracket frame 6E2 adopt an interference fit, and the corner bracket The frame 6E2 and the buckle collar 6E3 are fastened together, and the knuckle bracket frame 6E2 is pressed close to the wheel core through the lining support cap cushion seat 6E1 to form a disc frame type spacing steel bar pad protection against twisting operation.

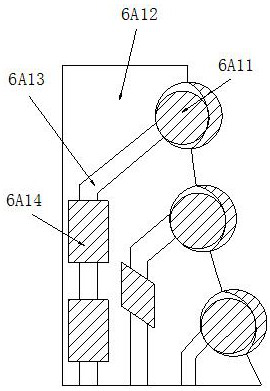

[0042] see Image 6 , the lining cap pad seat 6E1 is composed of pincer buckle plate 6E11, bow-shaped wing frame 6E12, arc top hat pad block 6E13, wheel buckle column plate 6E14, and the pincer buckle plate 6E11 and bow-shaped wing frame 6E12 are all inserted into the inside of the arc top hat spa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com