Multi-channel fluorescent optical fiber temperature transmitter and temperature measuring method

A technology of temperature transmitter and fluorescent optical fiber, applied in thermometers, thermometers with physical/chemical changes, instruments, etc., can solve the problems of large measurement errors and low precision, and achieve fast temperature acquisition speed, data stability and accuracy high degree of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

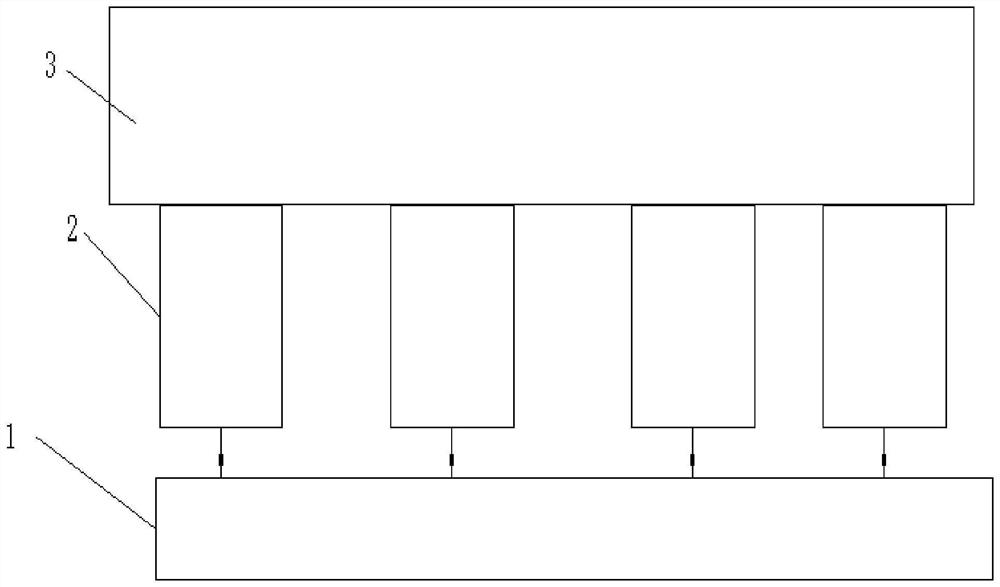

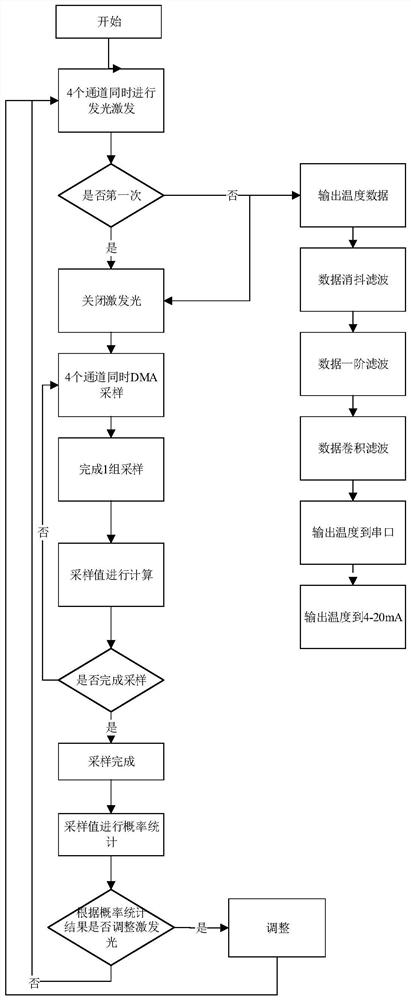

[0057] Such as figure 1 As shown, this embodiment uses the above-mentioned fluorescent optical fiber temperature sensor technology to propose a multi-channel fluorescent optical fiber temperature transmitter adapted to the plasma environment, including a data processing unit 1 and 4 temperature measurement units 2, 4 temperature measurement units 2 Temperature monitoring can be performed on different positions of the tested object; in other embodiments, the number of temperature measuring units 2 can be reasonably designed according to actual needs.

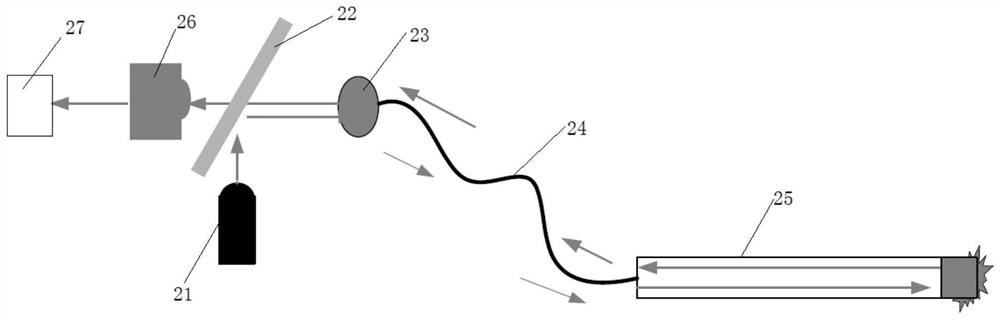

[0058] Such as figure 2 As shown, each temperature measurement unit 2 includes a light source generator 21, a filter plate 22, a filter lens 23, an optical fiber 24, an optical fiber probe 25, an optical sensor 26 and an amplifier 27, and the optical fiber probe 25 is arranged on the surface of the tested object 3; the light source generates The light beam emitted by the device 21 is incident on the filter 22, filtered and refl...

Embodiment 2

[0078] The difference from Example 1 is that step 2) obtains corresponding 4 first-time temperature data:

[0079] 2.1) Turn off the four light source generators 21;

[0080] 2.2) DMA controls 4 channels and simultaneously samples 4 channels at a sampling interval of 10us. DMA is the controller in data processing unit 1, and the 4 channels are respectively 4 temperature measurement units 2;

[0081] Four light sensors 26 simultaneously sample the first set of temperature data, and each channel collects the first sampling value A 1 ; With an interval of 10us, four light sensors 26 simultaneously sample the second set of temperature data, and each channel collects the second sampling value A 2 , 4 light sensors 26 obtain the first sampling value A of the excitation light for the first time 1 and the second sampled value A 2 ;

[0082] 2.3) With an interval of 10us, four light sensors 26 simultaneously sample the third set of temperature data, and each channel collects the th...

Embodiment 3

[0090] The difference from Embodiment 2 is that after multiple times of luminous excitation, the data processing unit 1 performs probability statistics on the temperature data obtained continuously by each temperature measuring unit 2, and according to the probability statistics results of the multiple continuous temperature data, Adjust the luminous intensity of the light source generator 21, specifically: when the proportion exceeding the predetermined setting value (threshold for short) in a plurality of continuous temperature data is greater than the required proportion, reduce the light intensity of the light source generator; When the proportion lower than the predetermined setting value (threshold value for short) is greater than the required proportion, the light intensity of the light source generator is increased. By adopting probability statistics data for the control of analog signal (sampling signal), the sampling signal control is adjusted by intelligent light sou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com