Boiler stable combustion control method for deep peak regulation working condition of coal-fired unit

A coal-fired unit, deep technology, applied in the direction of combustion method, combustion control, combustion equipment, etc., can solve the problems of complex operating characteristics of the unit, and achieve the effect of maintaining long-term safe and stable operation, improving sensitivity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

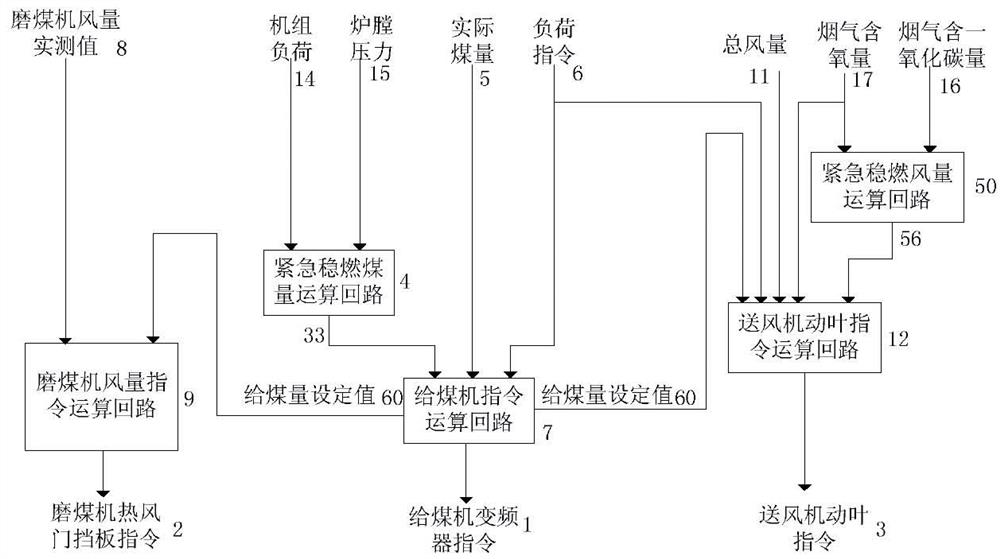

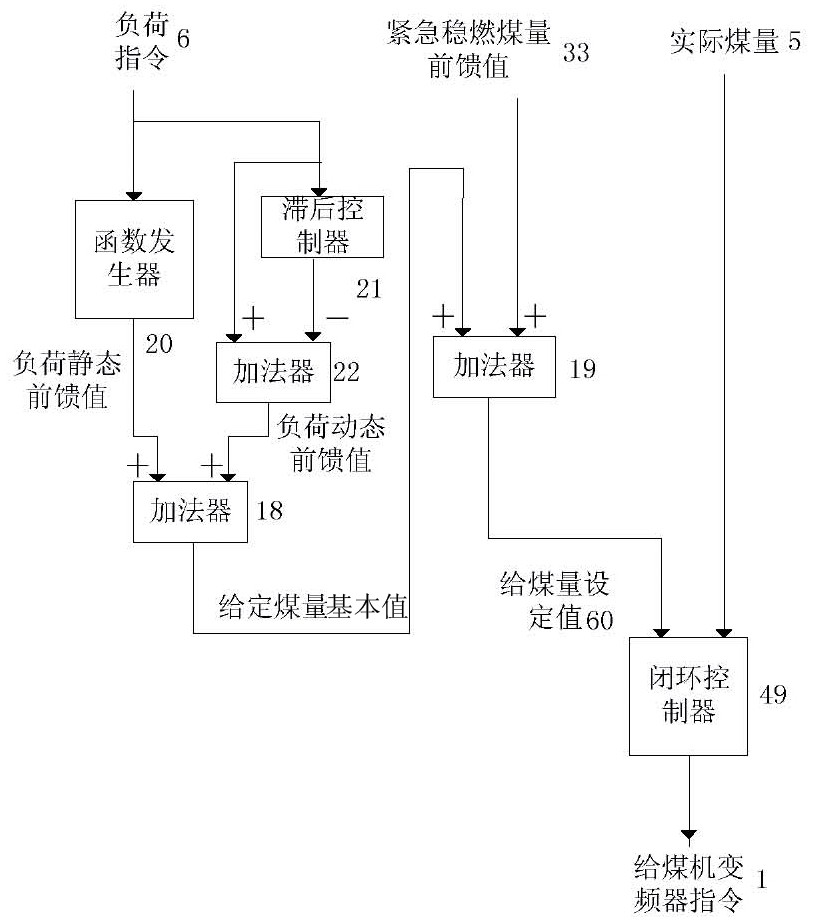

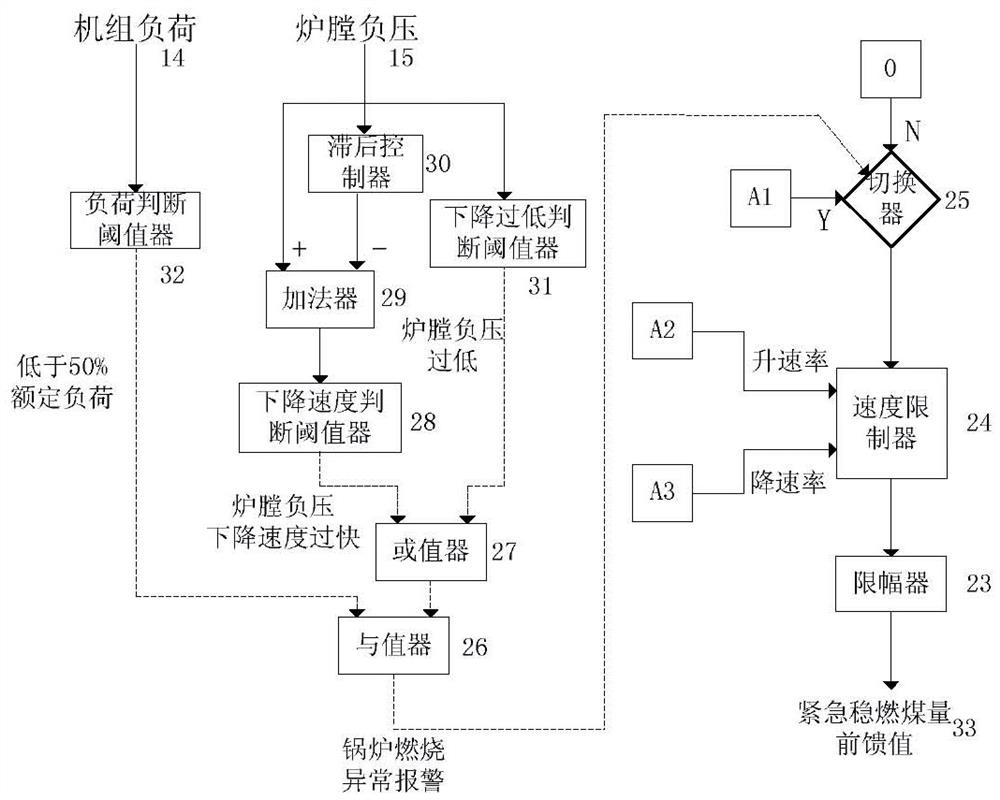

[0040] A boiler stable combustion control method for coal-fired units in deep peak-shaving conditions, such as Figure 1 to Figure 6 As shown, the method includes controlling the amount of coal fed into the boiler furnace through the coal feeder frequency converter instruction 1 in the existing normal control, and controlling the primary air volume and air supply required to transport pulverized coal by the coal mill hot air door baffle instruction 2 Motorized blade instruction 3 controls the secondary air volume entering the boiler furnace; wherein, under normal working conditions:

[0041] The inverter instruction 1 of the coal feeder is obtained by the actual coal quantity 5 transported by actual measurement and the load instruction 6 issued according to the load through the instruction operation circuit 7 of the coal feeder;

[0042] The hot air door damper command 2 of the coal mill is obtained from the set value 60 of the coal feed amount in the command operation circuit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com