Electromagnetically-driven organic solid waste pyrolysis system and method

An organic solid waste, electromagnetically driven technology, applied in combustion methods, lighting and heating equipment, combustion types, etc., can solve the problems of low energy utilization rate and high cost, and achieve the effect of improving heat energy utilization rate, low cost and reducing diffusion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1) Clean the bean dregs, filter out most of the water, put them in a drying oven, and set the temperature at 60-150°C to dry overnight.

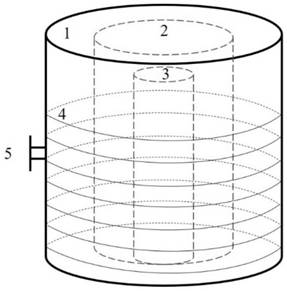

[0044] 2) Grind the dried okara into powder in a pulverizer, take an appropriate amount of okara powder and iron powder, mix them evenly, and put them into the inner tank 3 at a ratio of 1:1 to 1:10.

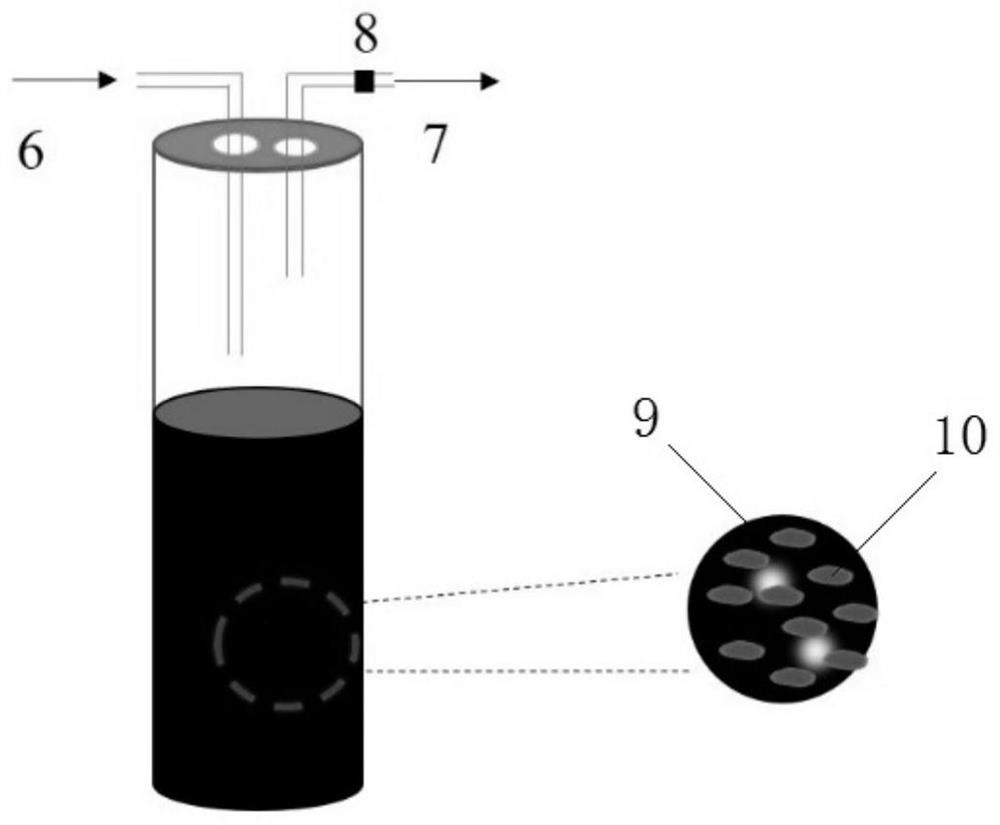

[0045] 3) Put the liner 3 into the cavity 2, cover the sealing cover and connect the intake pipe 6 and the exhaust pipe 7. Before the system starts to work, set the nitrogen gas on the controller 5 for 0 to 60 minutes to remove the internal gas. The air inside the gall 3.

[0046] 4) After the exhaust is finished, set the reaction time at 0-180min and the reaction temperature at 400-1000°C. After the parameter setting is completed, click Run on the controller 5, and the frequency conversion electromagnetic coil 4 will officially start running, and the inner tank 3 The iron powder in the absorbing electromagnetic coil 4 generates heat u...

example 2

[0051] 1) Clean the distiller's grain fine residue, filter out most of the water, put it into a drying oven, and set the temperature at 60-150°C to dry overnight.

[0052] 2) Grind the dried distiller's grains fine residue into powder in a pulverizer, take an appropriate amount of distiller's grain fine residue powder and iron powder, mix them evenly, and put them into the inner tank 3 at a ratio of 1:1 to 1:10.

[0053] 3) Put the liner 3 into the cavity 2, cover the sealing cover and connect the intake pipe 6 and the exhaust pipe 7. Before the system starts to work, set the nitrogen gas on the controller 5 for 0 to 60 minutes to remove the internal gas. The air inside the gall 3.

[0054] 4) After the exhaust is finished, set the reaction time at 0-180min and the reaction temperature at 400-1000°C. After the parameter setting is completed, click Run on the controller 5, and the frequency conversion electromagnetic coil 4 will officially start running, and the inner tank 3 The...

example 3

[0059] 1) Clean the bagasse, filter out most of the water, put it into a drying oven, and set the temperature at 60-150°C to dry overnight.

[0060] 2) The dried bagasse is crushed into powder in a pulverizer, and appropriate amount of bagasse powder and iron powder are mixed evenly and put into the inner tank 3 at a ratio of 1:1 to 1:10.

[0061] 3) Put the liner 3 into the cavity 2, cover the sealing cover and connect the intake pipe 6 and the exhaust pipe 7. Before the system starts to work, set the nitrogen gas on the controller 5 for 0 to 60 minutes to remove the internal gas. The air inside the gall 3.

[0062] 4) After the exhaust is finished, set the reaction time at 0-180min and the reaction temperature at 400-1000°C. After the parameter setting is completed, click Run on the controller 5, and the frequency conversion electromagnetic coil 4 will officially start running, and the inner tank 3 The iron powder in the iron powder absorbs the magnetic field generated by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com