Hall accelerator with sunken hollow inner magnetic pole structure

A Hall accelerator and inner magnetic pole technology, applied in the direction of machines/engines, using plasma, and thrust reversers, etc., can solve the problem of unstable discharge, Hall accelerator is not suitable for large scale scaling in size, and cathode surface etching and other problems, to achieve the effect of reducing the time for changing equipment, improving the working range and improving the efficiency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

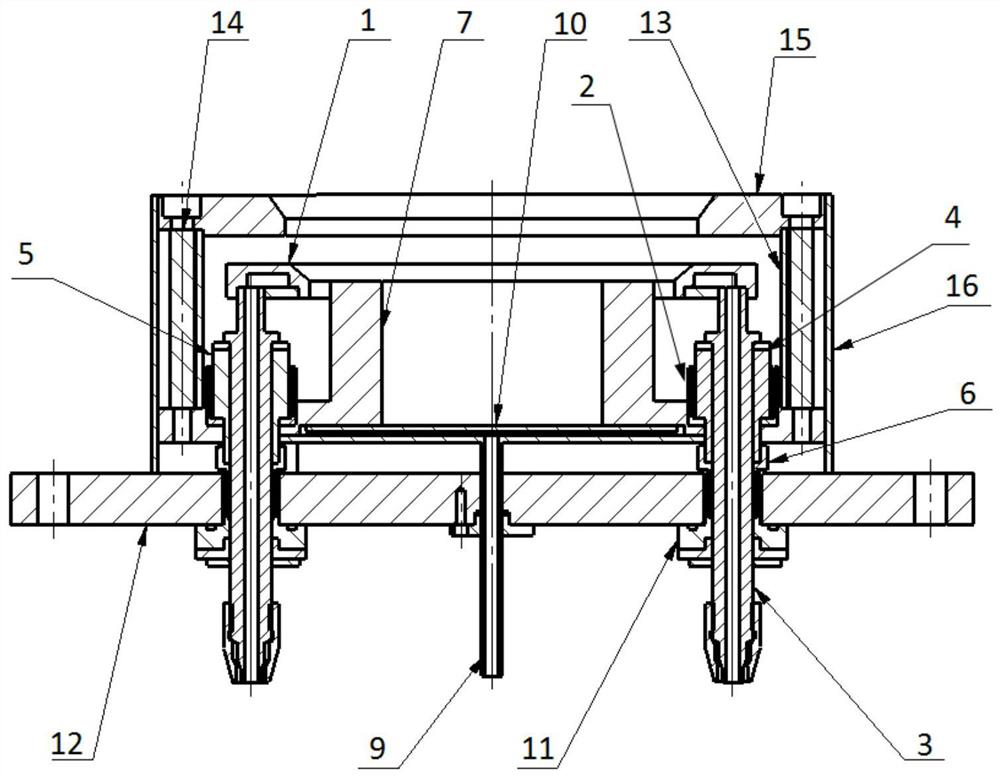

[0029]A Hall Accelerator of the present invention has a Hall Accelerator having a lower hollow inner magnetic pole structure of the present invention will be described in detail below with reference to the accompanying drawings and examples.

[0030]A Hall accelerator having a lower-type hollow pole structure, including: anode ring 1, a plurality of an inlet, an inner magnetic pole 7, an outer magnetic pole 15, an intake plate 9, an intake barrel 10, and supporting the flange 12, inner shield 13, outer shield 16, permanent magnet 14;

[0031]The lower portion of the inner magnetic pole 7 is fixed to the support flange 12 by a plurality of inlet and outlet nozzles; an outer shield 16 is provided on the upper surface of the support flange 12; an inner magnetic pole 7 and an inner shield are placed inside the outer shield 16. Cover 13; the inner shield 13 ring into the card slot of the outer magnetic pole 7;

[0032]A plurality of permanent magnets 14 are provided between the outer shield 16 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com