Steel-bamboo combined engineering bamboo beam-column connecting structure and preparation method thereof

A technology for connecting structures and bamboo beams and columns, applied in building structures, buildings, etc., can solve the problems of underutilized material strength, deformation control, etc., achieve good development and application prospects, reduce section size, and have good compressive resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. According to the following description, the purpose, technical solution and advantages of the present invention will be more clear. It should be noted that the described embodiments are preferred embodiments of the present invention, but not all embodiments.

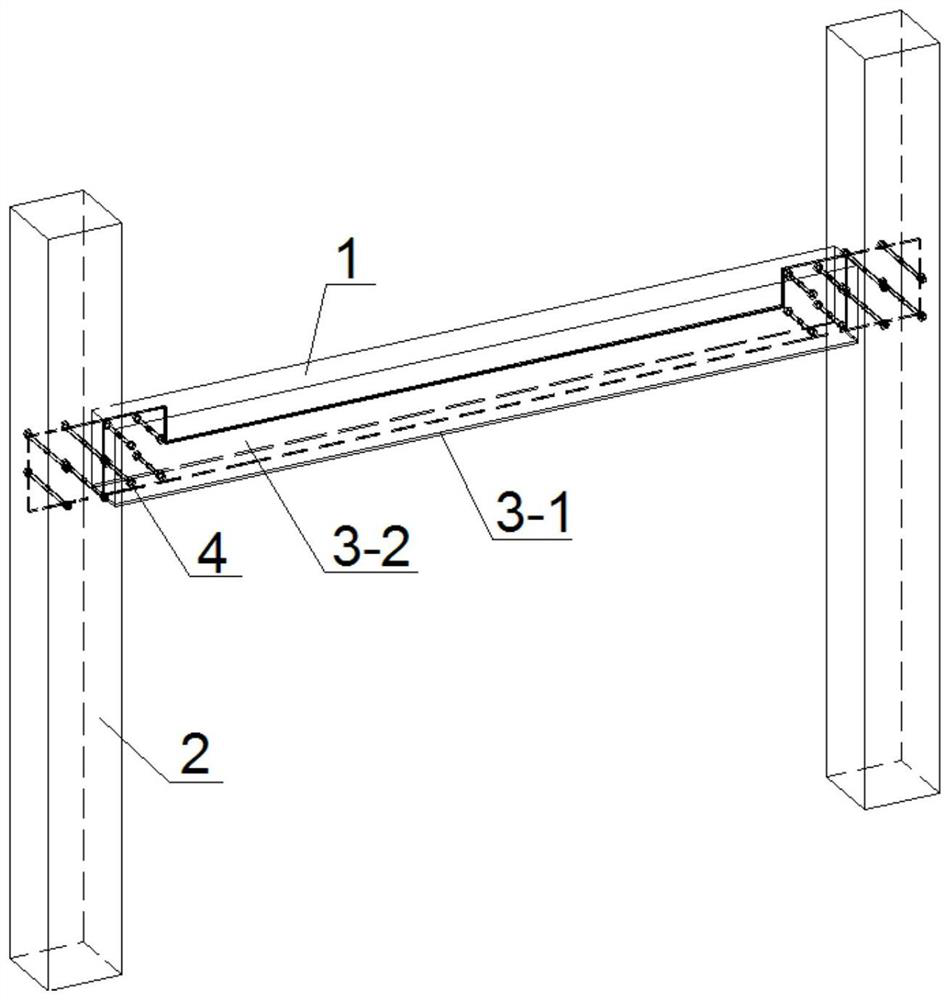

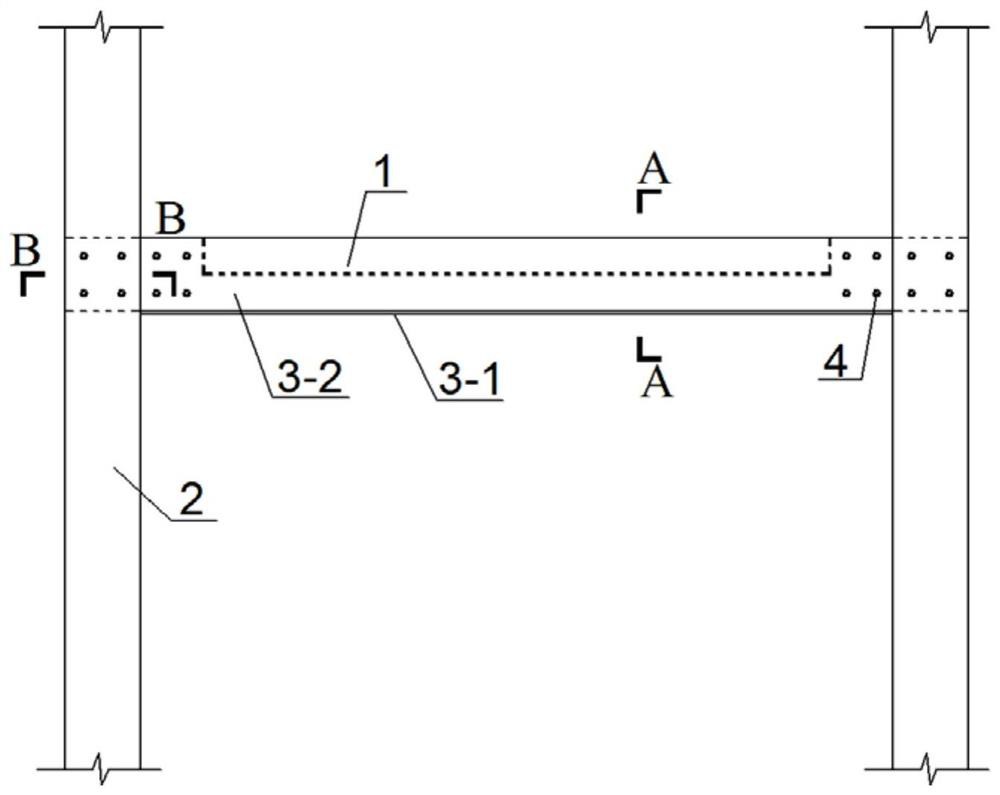

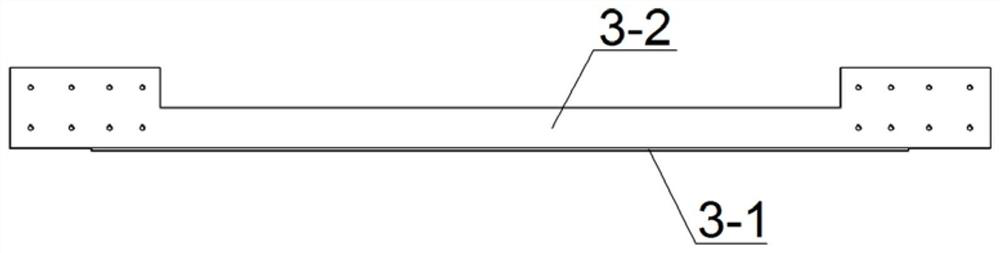

[0028] to combine figure 1 As shown, a steel-bamboo combined engineering bamboo beam-column connection structure includes two engineering bamboo columns 2 arranged symmetrically, engineering bamboo beams 1 erected between the engineering bamboo columns 2, a first steel plate 3-1 and a second steel plate 3-2.

[0029] The engineering bamboo beam 1 and the engineering bamboo column 2 are both made of glued bamboo or recombined bamboo laminates. The cross-sectional size of the engineering bamboo beam is 180mm×300mm, and the engineering bamboo column is 300mm×300mm. Both the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com