Volatile oil extraction separator with lining pipe

A technology for lining pipes and separators, which is applied in the directions of essential oils/spices, fat generation, etc., can solve the problems of increased contact surface of volatile oil and glass, inability to absorb volatile oil, and increased production cost, and achieves excellent chemical stability and excellent mechanical properties. Performance, effect of good anti-aging endurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

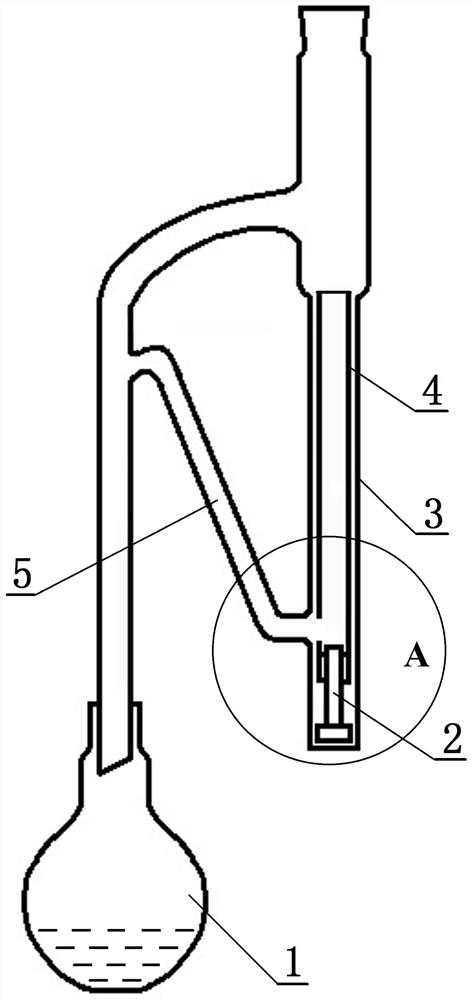

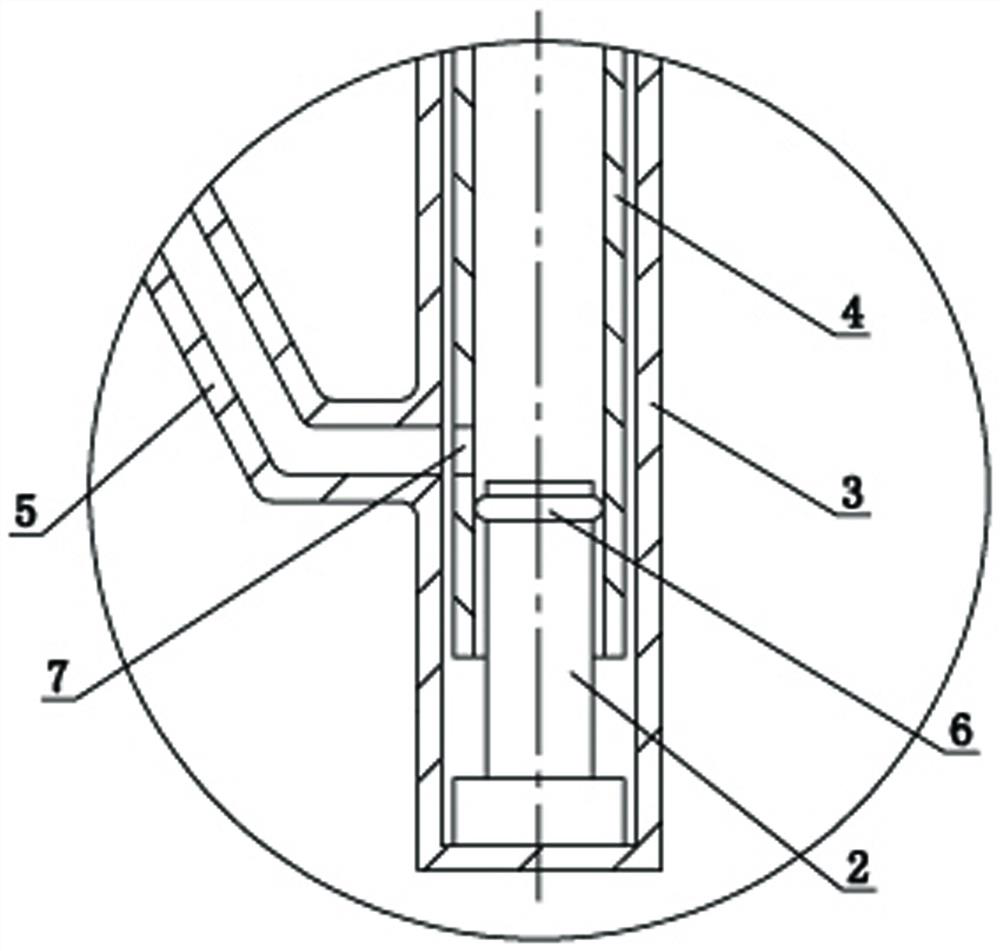

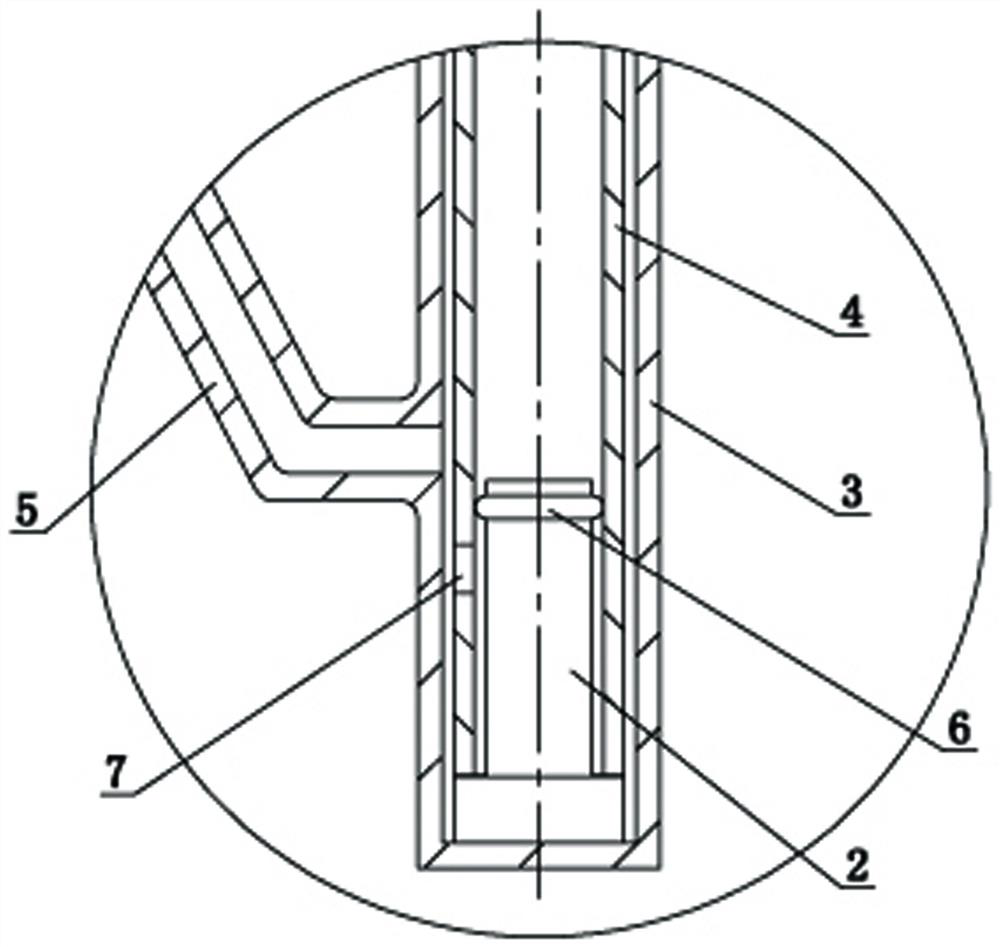

[0016] Embodiment 1: the present invention is the improvement to existing conventional volatile oil extraction separator, as figure 1 , figure 2 As shown, this improved volatile oil extraction separator with a liner includes an extractor assembled on the distillation bottle 1, the bottom end of the extractor separation pipe 3 is a blind end, and a The translucent liner 4 made of polytetrafluoroethylene, the gap between the liner 4 and the separation pipe 3 is preferably kept no greater than 0.6mm. When water is injected into the separation pipe 3, the inner wall of the separation pipe 3 and the liner A simple water seal can be formed between the outer walls of the tubes 4. An opening 7 is arranged on the tube wall of the liner tube 4, and a plunger 2 is set at the bottom end of the liner tube 4 made of polytetrafluoroethylene. The tube 4 is tightly fitted with the plunger 2, or the sealing rubber ring 6 is installed on the upper part of the plunger 2, and the installed seali...

Embodiment 2

[0017] Embodiment 2: The difference between this embodiment and Embodiment 1 is that a glass tube with a translucent polytetrafluoroethylene coating is placed on the inner wall of the separation tube 3, that is, the inner liner 4 has a translucent polytetrafluoroethylene coating on the inner wall. Coated glass tubes.

[0018] In the present invention, before the distillation material, at first the plunger 2 at the bottom of the liner pipe 3 is placed as figure 2 As shown in the collection state, put the inner liner 4 into the separation pipe 3 with an auxiliary tool, turn the inner liner 4 properly so that the opening 7 on the side wall corresponds to the water inlet of the overflow pipe 5, and then remove from the separation pipe 3. Add water to the inlet of the top along its inner wall, and the amount of water added can overflow into the distillation flask 1 from the overflow pipe 5 connected with the separation pipe 3. Afterwards, according to the distillation operation p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com