A magnetic liquid polishing device for optical lens processing

A magnetic liquid and polishing device technology, applied in the direction of grinding/polishing safety devices, optical surface grinders, metal processing equipment, etc., can solve the problems of time-consuming, complicated adjustment, cumbersome structure, etc., to improve the efficiency of disassembly and assembly, adjustment The effect of simple method and simple position adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

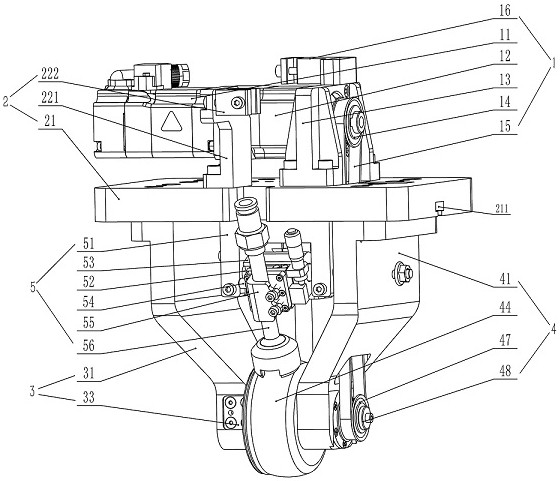

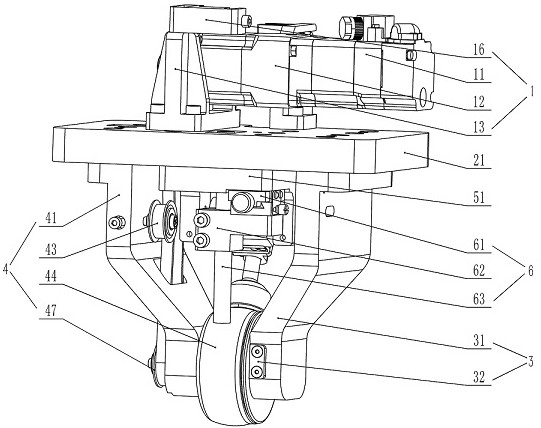

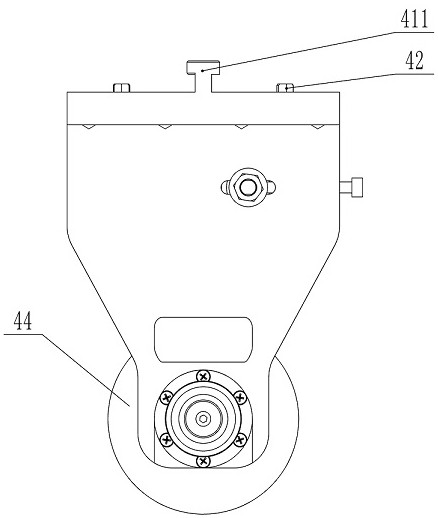

[0032] Such as Figure 1 to Figure 8 As shown, a magnetic liquid polishing device for optical lens processing includes a motor assembly 1, a motor 11, a reducer 12, a motor mounting seat 13, a main timing pulley 14, a timing belt 15, and a liquid inlet pipe clamping seat 16. Installation and fixing device 2, installation and fixing plate 21, chute 211, T-shaped slider avoidance hole 212, pipe clamp seat 221, pipe clamp 222, left arm module 3, left installation arm 31, magnetic field generator 32, installation Block 33, cover plate 34, right arm module 4, right mounting arm 41, slider 411, tapered pin 42, tensioning wheel 43, tensioning wheel shaft 431, polishing wheel 44, rolling bearing 45, sleeve 46, driven synchronization Pulley 47, retaining ring 48, recovery device 5, mounting seat 51, support shaft 52, recovery pipe seat 53, up and down ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com