Control method and device for residual steel amount of steel ladle and storage medium

A control method and technology of ladle, applied in the direction of manufacturing tools, casting melt containers, casting equipment, etc., can solve the problems of increasing the critical height of the vortex, harming the cleanliness of molten steel, and increasing the cost of steelmaking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

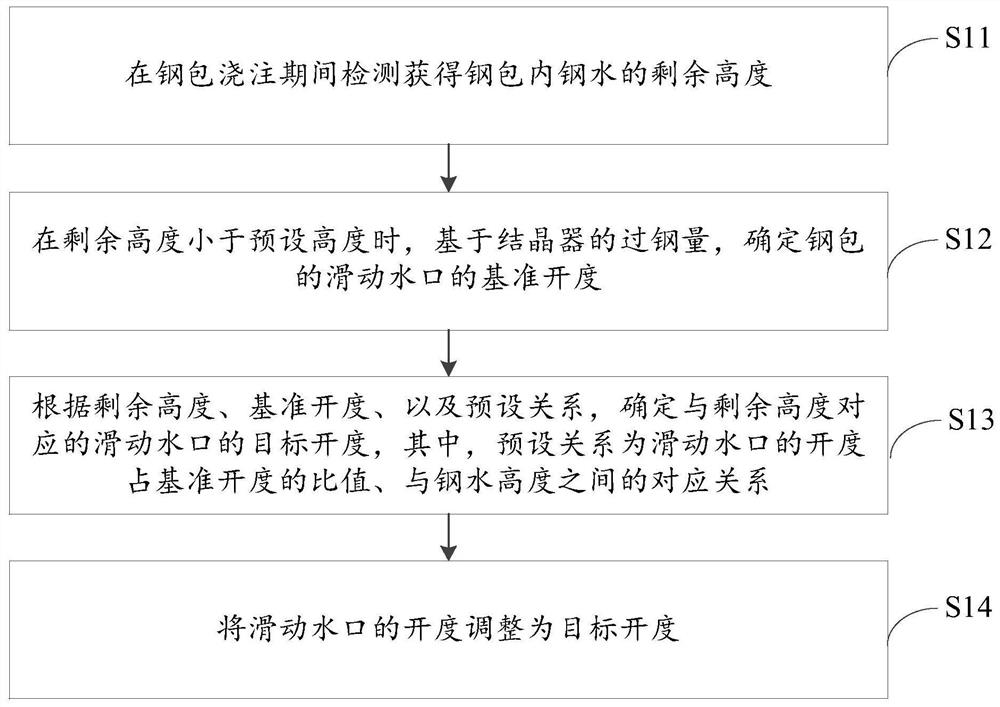

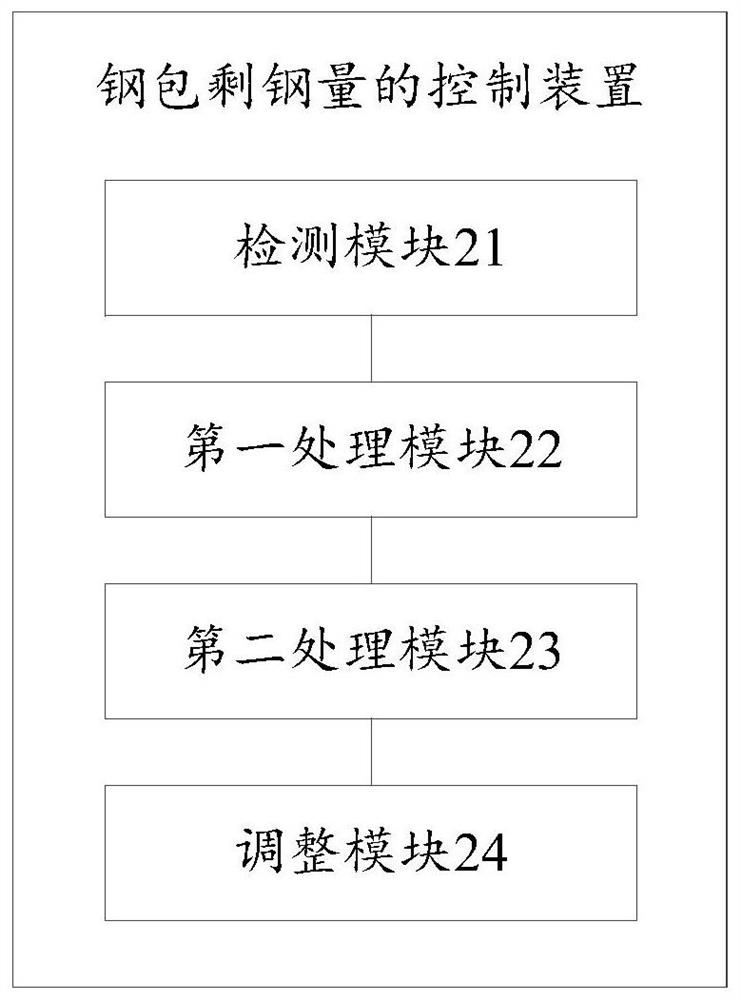

[0059] The embodiments of the present invention provide a control method, device and storage medium for remaining steel in a ladle, which are used to reduce the remaining steel in a ladle and increase the yield of molten steel. The method includes: detecting and obtaining the remaining height of molten steel in the ladle during pouring of the ladle; when the remaining height is less than a preset height, determining the reference opening of the sliding nozzle of the ladle based on the steel passing amount of the mold; degree, and the preset relationship to determine the target opening of the sliding nozzle corresponding to the remaining height, wherein the preset relationship is the ratio of the opening of the sliding nozzle to the reference opening and the correspondence between the height of the molten steel; the sliding nozzle Adjust the opening to the target opening.

[0060] The technical solutions of the present invention will be described in detail below through the acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com