Integrated clamp with functions of shearing and bending kirschner wire

A technology for bending Kirschner wires and Kirschner wires, which is applied in the field of integrated forceps with functions of cutting and bending Kirschner wires, and can solve problems such as long operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

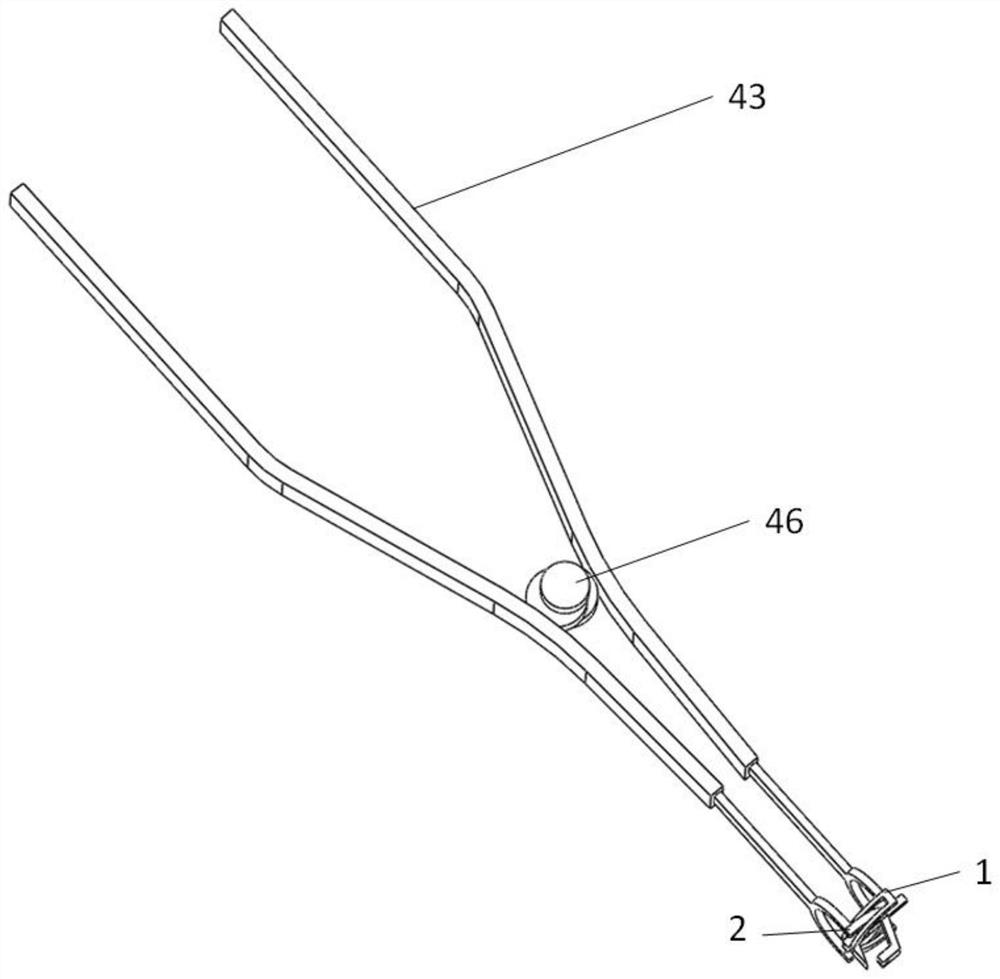

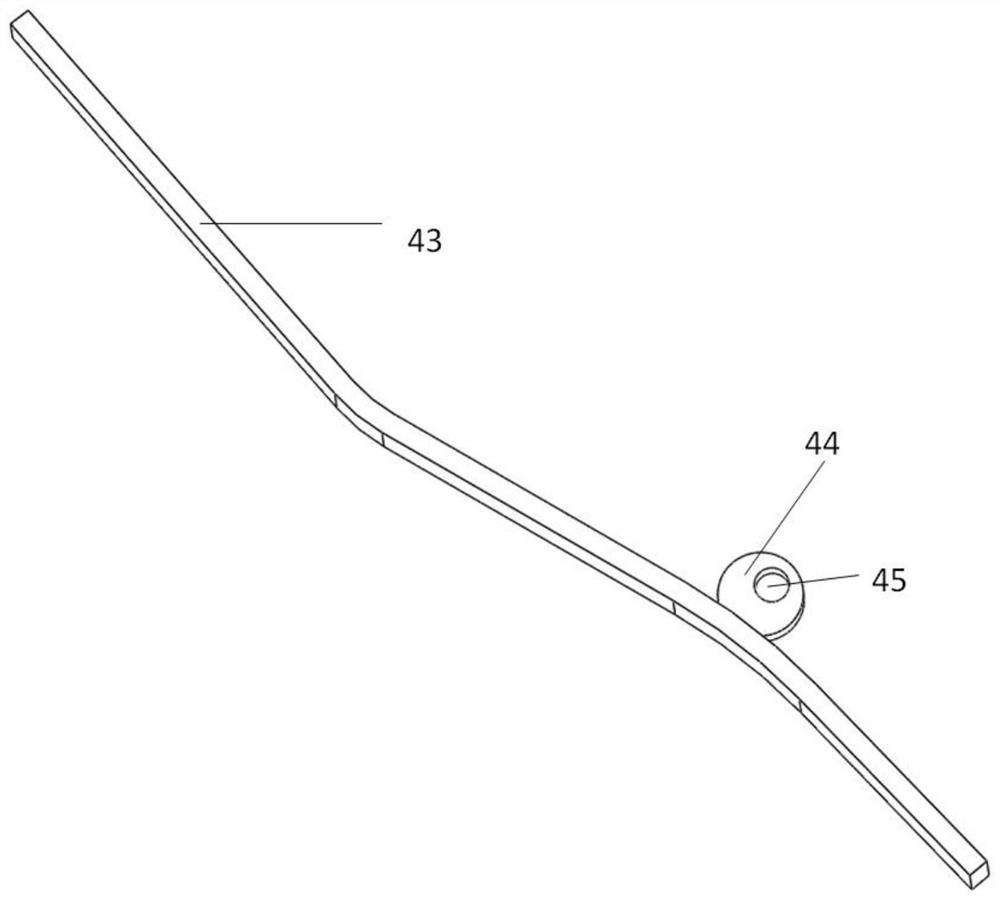

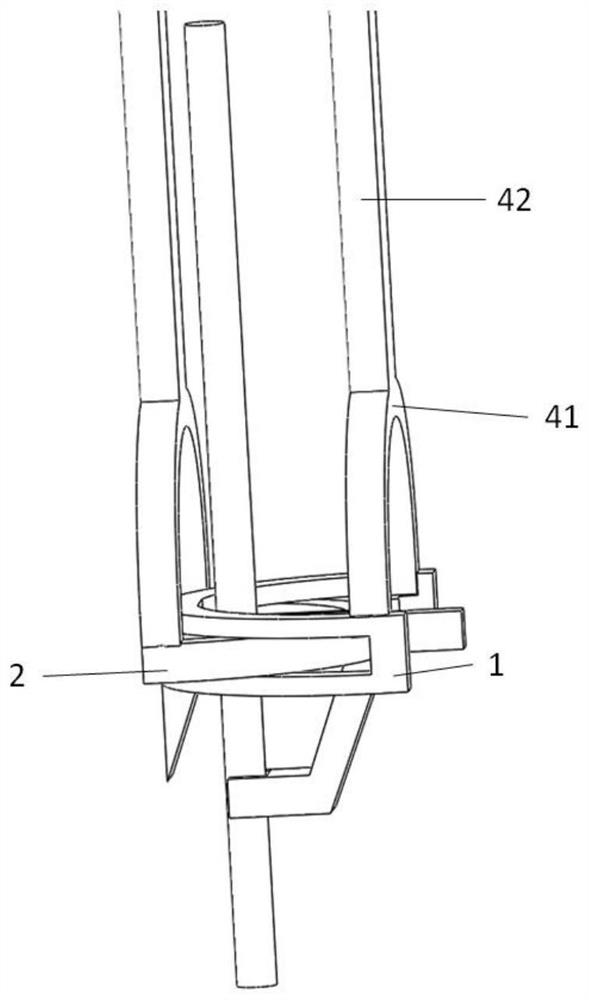

[0045] Embodiment 1 An integrated forceps with functions of cutting and bending Kirschner wires

[0046] An integrated pliers with the function of cutting and bending Kirschner wires, which includes two 180° arc structures with overlapping parts, and a pliers handle 43 that controls the center of the arc structures to move relatively far away; it is characterized in that, A Kirschner wire is inserted into the overlapping part of the two arc structures; a shearing structure for shearing the Kirschner wires is set on the two arc structures when they move with each other; The lower end is a bending structure with a bending angle of 90°; the shearing structure includes a shearing knife 21 protruding from any one or two arcuate structures; the shearing knife 21 extends from the annular edge of the arcuate structure to the overlapping portion and the initial state of motion after the shear knife 21 extends into the overlapping part does not affect the insertion of the Kirschner wire...

Embodiment 2

[0054] Embodiment 2 An integrated forceps with functions of cutting and bending Kirschner wires

[0055] An integrated pliers with the function of cutting and bending Kirschner wires, which includes two 180° arc structures with overlapping parts, and a pliers handle 43 that controls the center of the arc structures to move relatively far away; it is characterized in that, A Kirschner wire is inserted into the overlapping part of the two arc structures; a shearing structure for shearing the Kirschner wires is set on the two arc structures when they move with each other; The lower end is a bending structure with a bending angle of 90°; the shearing structure includes a shearing knife 21 protruding from any one or two arcuate structures; the shearing knife 21 extends from the annular edge of the arcuate structure to the overlapping portion and the initial state of motion after the shear knife 21 extends into the overlapping part does not affect the insertion of the Kirschner wire...

Embodiment 3

[0064] Embodiment 3 An integrated forceps with functions of cutting and bending Kirschner wires

[0065] An integrated pliers with the function of cutting and bending Kirschner wires, which includes two 180° arc structures with overlapping parts, and a pliers handle 43 that controls the center of the arc structures to move relatively far away; it is characterized in that, A Kirschner wire is inserted into the overlapping part of the two arc structures; a shearing structure for shearing the Kirschner wires is set on the two arc structures when they move with each other; The lower end is a bending structure with a bending angle of 90°; the shearing structure includes a shearing knife 21 protruding from any one or two arcuate structures; the shearing knife 21 extends from the annular edge of the arcuate structure to the overlapping portion and the initial state of motion after the shear knife 21 extends into the overlapping part does not affect the insertion of the Kirschner wire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com