Photodiode

A photodiode and electrode technology, applied in circuits, lasers, electrical components, etc., can solve the problems of low utilization rate of side-incident MPD lasers, and achieve the effect of reducing chip size and improving responsivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

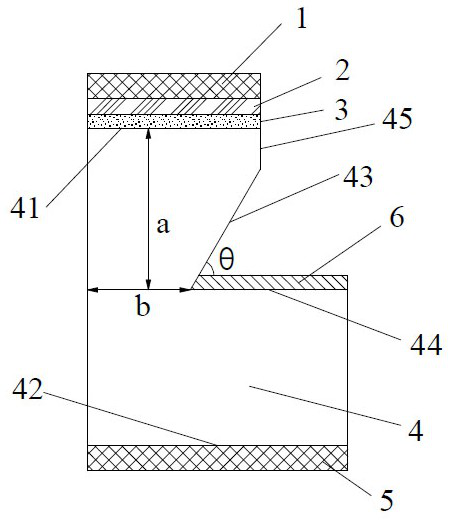

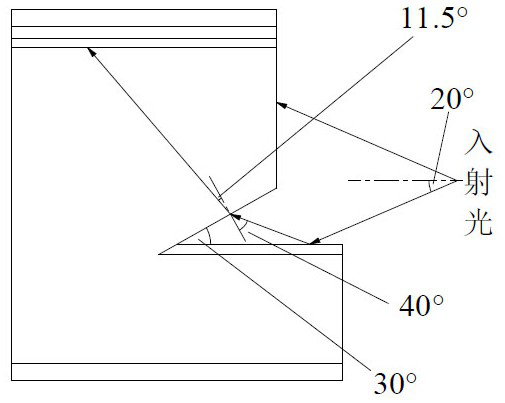

[0030] Embodiment 1: Because the top surface 41, the first incident surface 43 and the mesa 44 indirectly form a zigzag (extend the top surface 41 and the incident surface 43 to intersect), the angle formed by the first incident surface 43 and the mesa 44 θ is 30°, and the divergence angle of the laser is 40° as an example. Since the height a of the mesa 44 will affect the receiving area of light incident, the vertical distance from the mesa 44 to the top surface 41 is ≥ 2 μm. In the first embodiment, taking θ as 30° as an example, the height a of the mesa 44 is 2 μm, and the width of the unopened part of the N-type substrate 4 on the plane where the mesa 44 is located is b, and b>1.77 μm can ensure that light is incident on the photosensitive Layer 3.

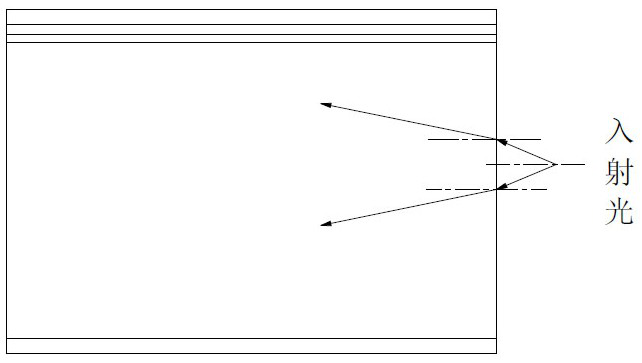

[0031] The photodiode of the present invention is used as a side-incidence MPD (MPD is a monitor photodiode, which is a device for monitoring the light output of a laser), and the side-emitting laser is placed next to the si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com