Cellulose-coated graphene composite carbon aerogel as well as preparation method and application thereof

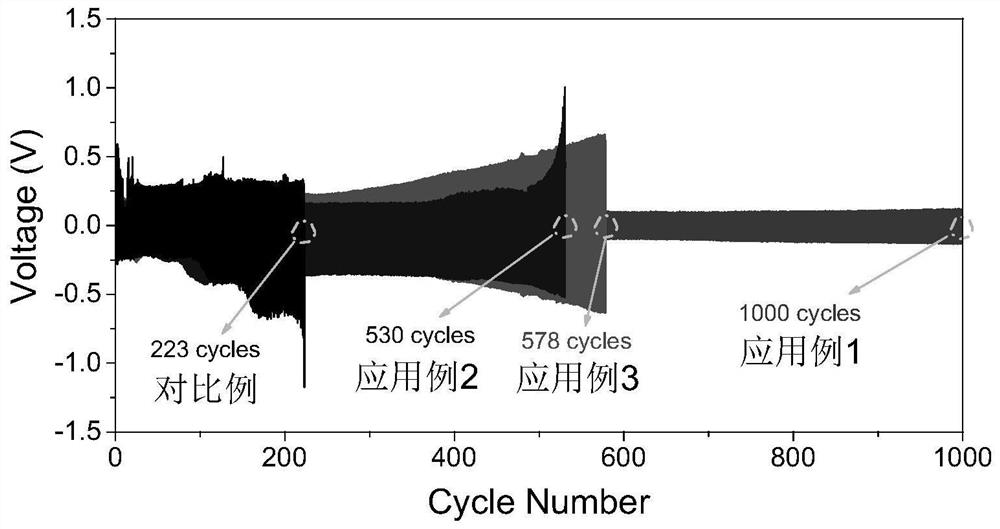

A graphene airgel and graphene composite technology, which is applied in the preparation/purification of carbon, electrical components, secondary battery repair/maintenance, etc., can solve the problem of safety of battery separator, inability to change the upward growth direction of dendrites, and hidden dangers and other issues, to achieve the effect of improving cycle life, improving long-term cycle stability, and prolonging cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

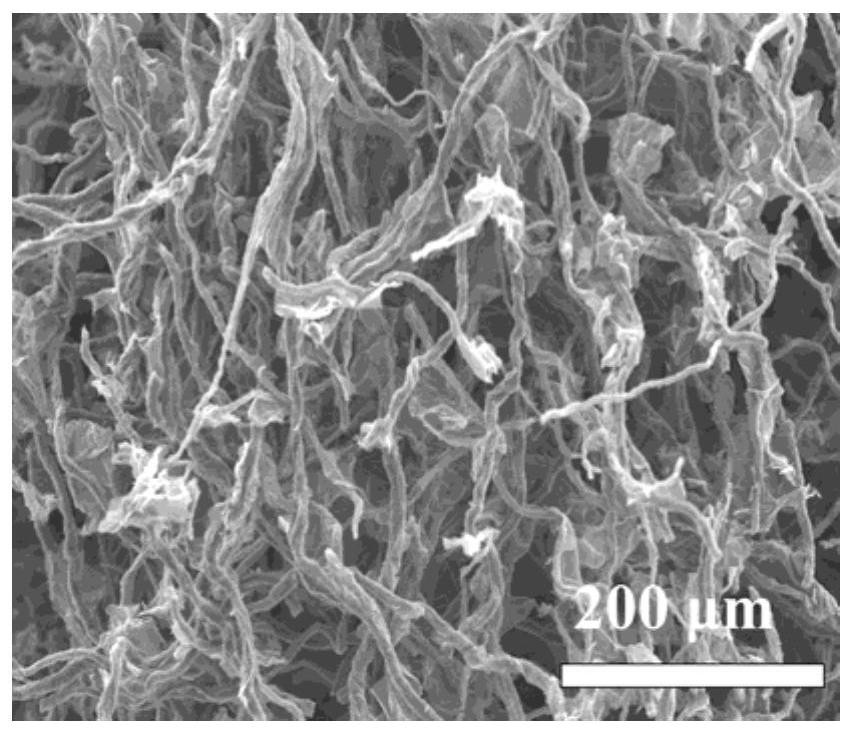

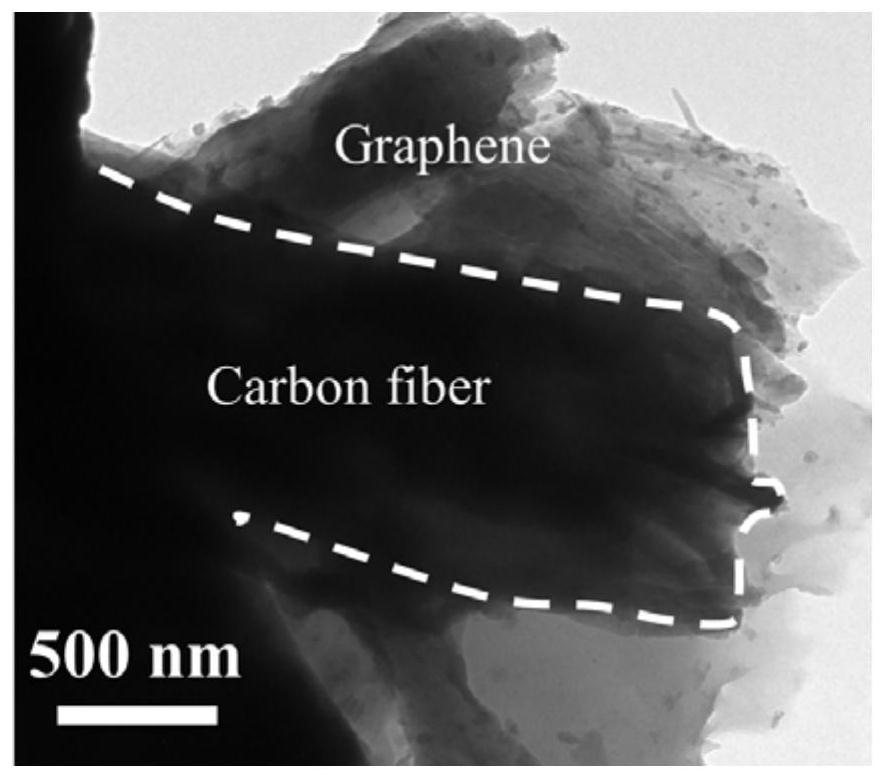

[0033] Step 1: Preparation of Cotton Cellulose / NaOH / H 2 O (1.0g / 7.6g / 32.4ml) mixed solution; place at -15°C for 12h;

[0034] Step 2: Place the above mixed solution at -15°C for 12 hours, then mix it with graphene oxide solution (2mg / ml) at low temperature, and stir vigorously to obtain a mixed solution of cellulose@graphene oxide;

[0035] Step 3: Pour the cellulose@graphene oxide mixed solution into the mold and let it stand at room temperature for 48 hours to obtain the cellulose@graphene oxide hydrogel;

[0036] Step 4: Cellulose@graphene oxide hydrogel is freeze-dried to obtain cellulose@graphene oxide airgel;

[0037] Step 5: Heat up the cellulose@graphene oxide airgel to 800°C at a heating rate of 2°C / min in an Ar atmosphere, and pyrolyze it for 2 hours to obtain the cellulose@graphene composite carbon aerogel (CCA ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com