High-grade non-oriented silicon steel and production method thereof

A technology of oriented silicon steel and its production method, which is applied in the production field of high-grade non-oriented silicon steel, and achieves the effects of low production cost, excellent magnetic properties and reduced process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

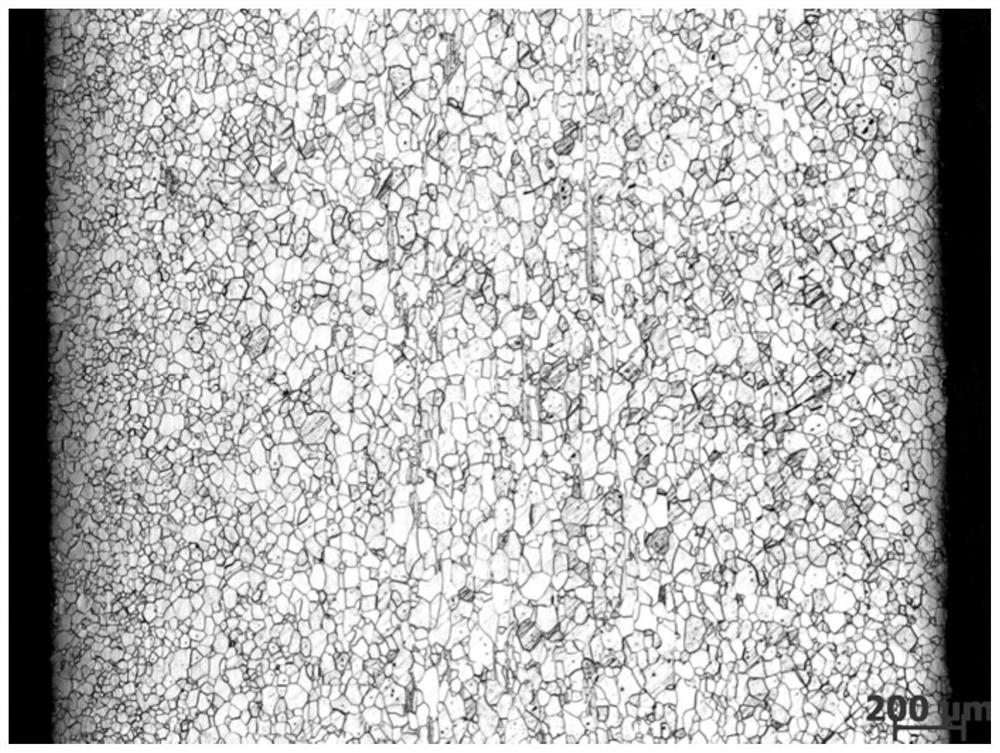

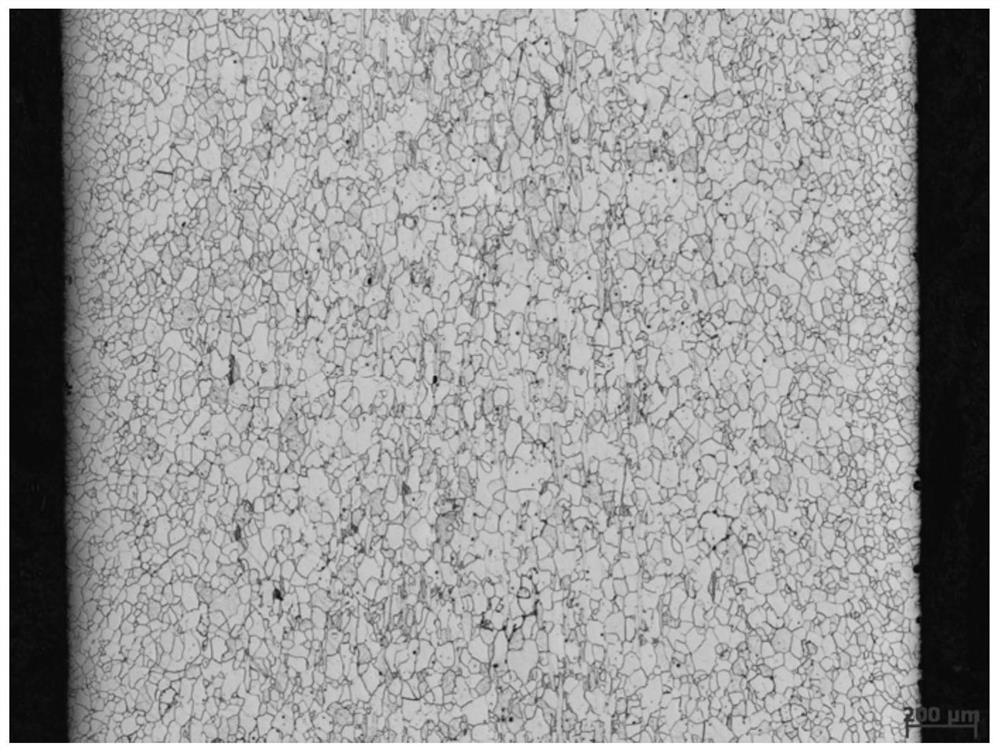

[0045] One embodiment of the present invention provides a production method of high-grade non-oriented silicon steel, and high-grade non-oriented silicon steel prepared by the production method. The production method includes the following processes in sequence: molten iron desulfurization, converter smelting, RH refining, continuous casting, hot rolling, acid continuous rolling, annealing, cooling, coating and finishing, and normalization treatment is not required before acid continuous rolling , and the obtained non-oriented silicon steel has good magnetic properties and no corrugated defects on the surface, which meets the requirements of low-cost and high-grade non-oriented silicon steel.

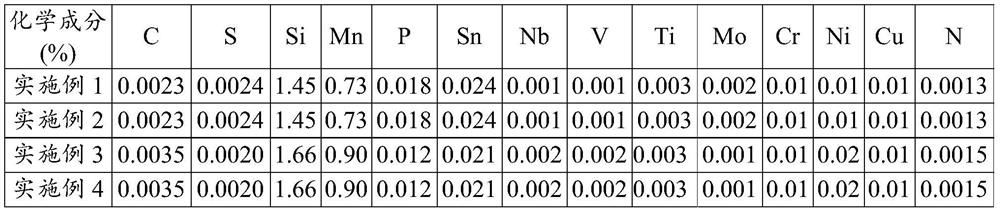

[0046] In this embodiment, the chemical composition design scheme of the non-oriented silicon steel is as follows, and its chemical composition is calculated by mass percentage: C: 0.002-0.004%, S≤0.003%, Si: 1.4-1.7%, Mn: 0.7-0.95 %, P≤0.03%, Sn:0.015~0.035%, Nb≤0.004%, V≤0.004%, Ti≤0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com