Preparation method of pellets for reducing emission of SO2 and NOx in sintering process

A sintering process and pelletizing technology, which is applied in the field of pollutant emission reduction in the sintering process, can solve the problems of poor emission reduction effect and high cost of flue gas treatment, and achieve improved emission reduction efficiency, high emission reduction efficiency of flue gas, and wide application. Foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

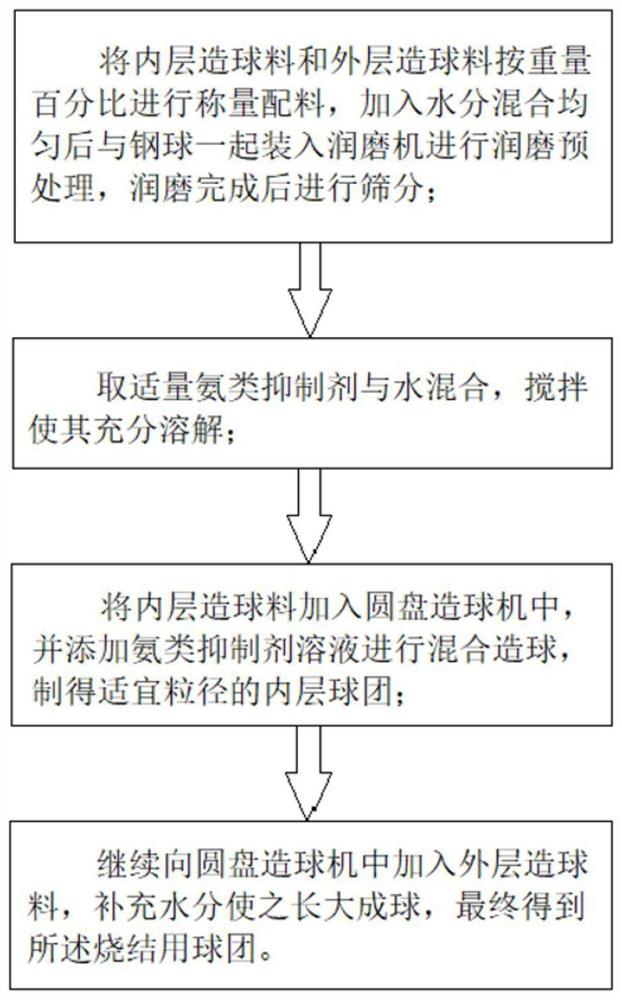

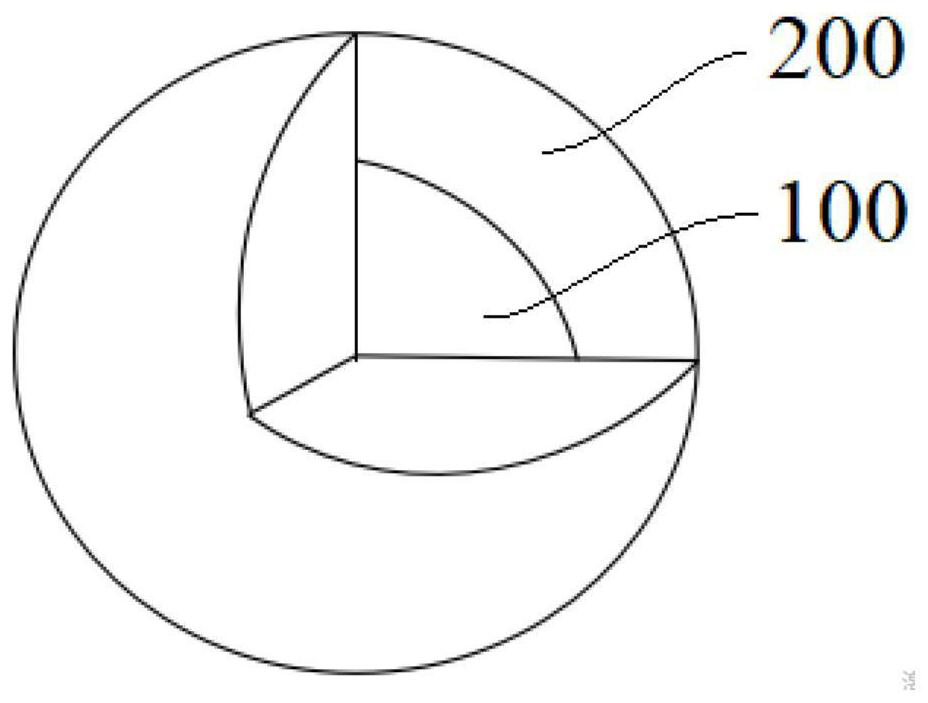

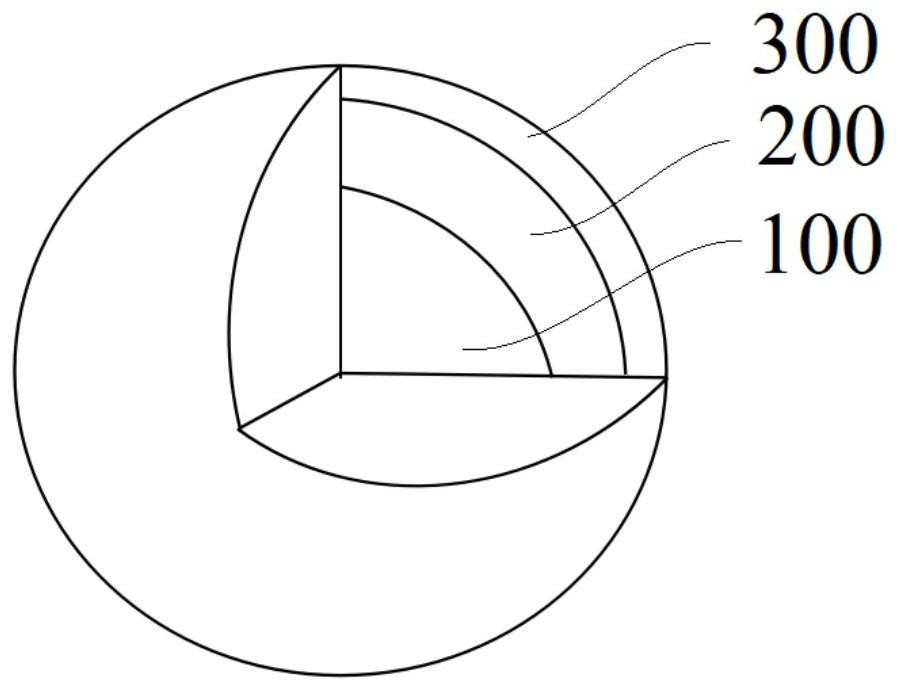

[0036] Such as figure 1 As shown, a method for preparing pellets used in the sintering process to reduce SO2 and NOx emissions in this embodiment first prepares the inner layer pellets 100, and the inner layer pellets 100 include inner layer pelletizing material and ammonia Inhibitors, the ammonia inhibitors are thermally decomposed to release ammonia, and the N element content in the ammonia inhibitors accounts for 0.02-0.15% of the mass of the inner pellets, in this embodiment, it is 0.047%, which is converted into urea The mass ratio is 0.1%; and then prepare a wrapping layer 200 on the outside of the inner pellet 100, and the wrapping layer 200 includes an outer layer of pelletizing material; the particle size of the outer layer of pelletizing material reaches -0.149mm particle size mass percentage content ≥ 95%; the particle size of the inner layer pelletizing material reaches -0.074mm particle size mass percentage content ≥ 95%; the particle size of the inner layer pelle...

Embodiment 2

[0063] The preparation method and sintering emission reduction method of the pellets in this embodiment are basically the same as in Embodiment 1, except that the N element content of the ammonia inhibitor in this embodiment accounts for 0.038% of the mass of the inner pellet 100, The mass ratio converted to urea is 0.08%, the detection of SO 2 , NO X and the concentration of dioxins are recorded in Table 4, and the desulfurization and denitrification rate and the emission reduction efficiency of dioxins are calculated.

Embodiment 3

[0065] The preparation method and sintering emission reduction method of the pellets in this embodiment are basically the same as in Embodiment 1, except that the N element content of the ammonia inhibitor in this embodiment accounts for 0.071% of the mass of the inner pellet 100, The mass ratio converted to urea is 0.15%, the detection of SO 2 , NO X and the concentration of dioxins are recorded in Table 4, and the desulfurization and denitrification rate and the emission reduction efficiency of dioxins are calculated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com