Equipment for reducing internal stress of injection-molded part and injection-molding production method

A technology of injection molded parts and internal stress, which is applied in the field of injection molding production equipment, can solve the problems of stress marks on the surface of injection molded parts, dents on the surface of injection molded parts, and stress generation, so as to avoid poor plasticization and ensure the plasticization ability of mixed materials , the effect of reducing internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

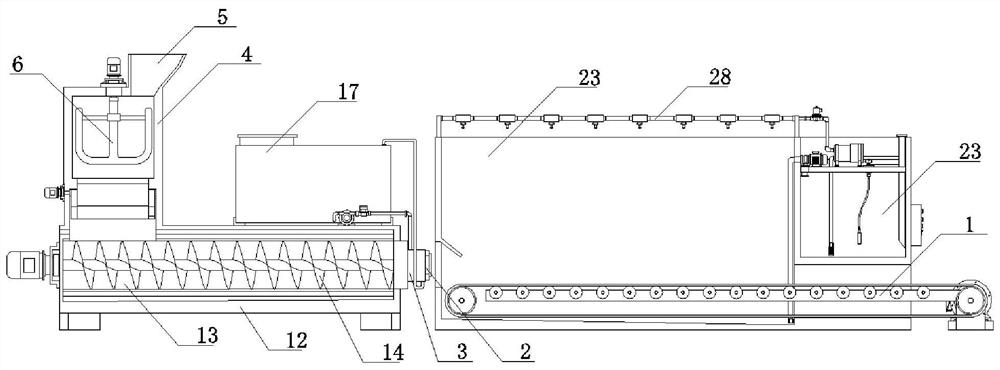

[0037] see Figure 1 , a device for reducing the internal stress of injection molded parts, comprising a raw material mixing assembly, an injection molding assembly, an injection cooling assembly, a finished product cooling assembly and a conveyor belt 1, the raw material mixing assembly is connected to the injection molding assembly, and an injection mold 2 is connected to the outlet of the injection molding assembly, The outside of the injection mold 2 is provided with a cooling cavity 3, the cooling cavity 3 is connected with the injection cooling assembly, the finished cooling assembly is located at the side of the injection mold 2, and the conveyor belt 1 is arranged in the finished cooling assembly.

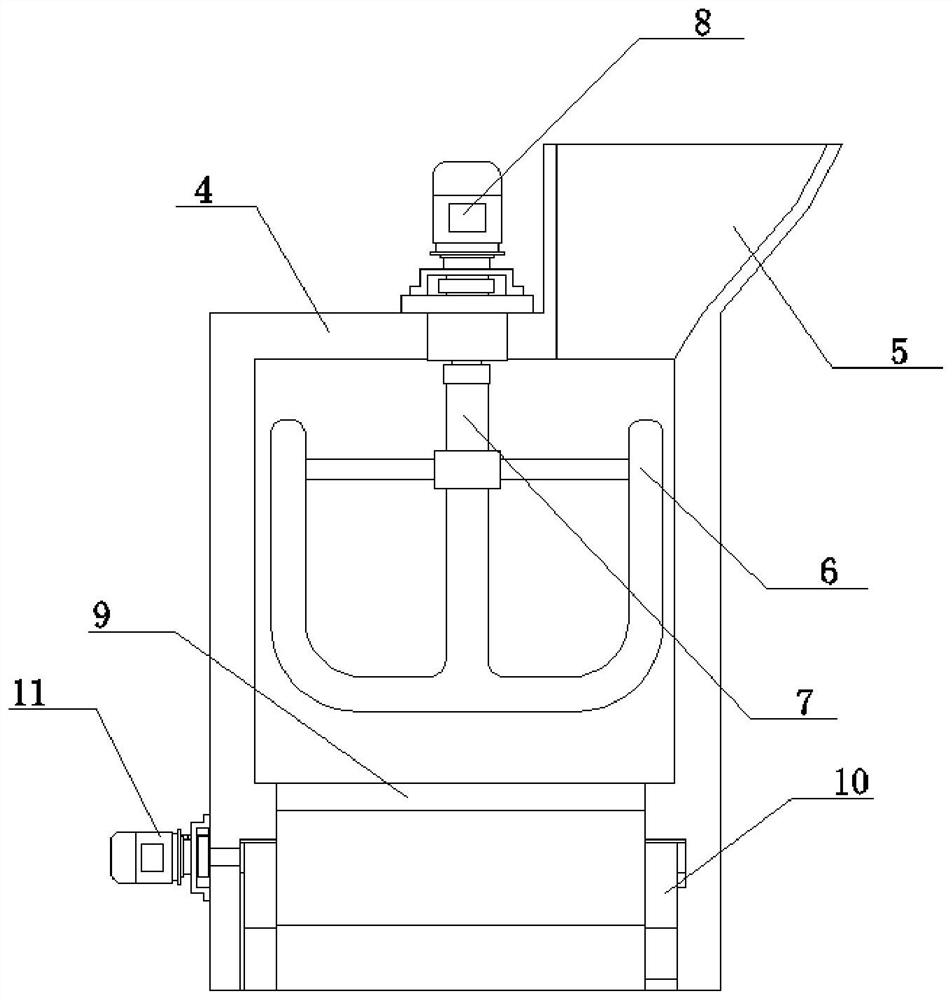

[0038] see Figure II , the raw material mixing assembly includes a stirring tank 4, the top of the stirring tank 4 is provided with a feed hopper 5, the stirring tank 4 is provided with an agitator 6, the upper end of the agitator 6 is fixedly connected with a rotating sha...

Embodiment 2

[0044] An injection molding production method for equipment for reducing internal stress of injection molded parts, specifically comprising the following implementation steps:

[0045] Step 1, the material particles are poured into the stirring tank 4 through the feed hopper 5, the stirring motor 4 is started, the stirring motor 4 drives the agitator 6 to rotate through the rotating shaft 7, and the materials in the stirring tank 4 are mixed and stirred;

[0046] Step 2, after the materials are mixed, the gate motor 11 is started, and the gate motor 11 drives the gate 10 to start discharging, and the material enters the barrel 13 through the discharge port 9;

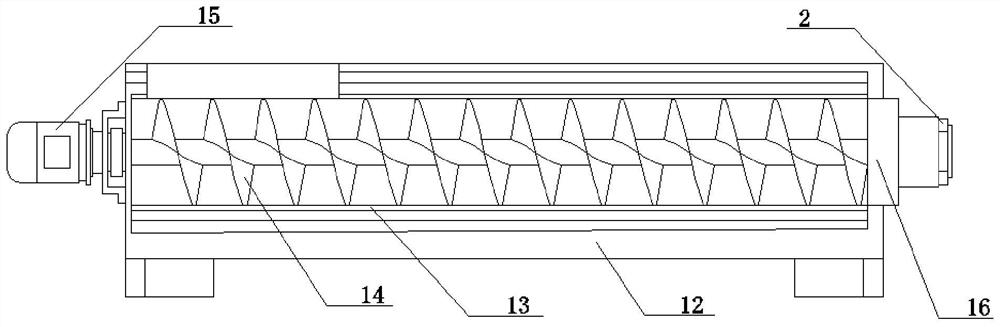

[0047] Step 3, the heating tube heats the material in the barrel 13, and after the material is melted, the injection motor 15 drives the screw 14 to rotate, the screw 14 squeezes the material and pushes it to the discharge end 16, and the material enters the injection mold 2 through the nozzle;

[0048] Step 4, the circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com