Cooling fin self-punching equipment for CPU radiator

A heat sink and self-punching technology, applied in heat exchange equipment, metal processing equipment, feeding devices, etc., can solve the problems of time-consuming and high production costs, and achieve the effect of fully automated operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

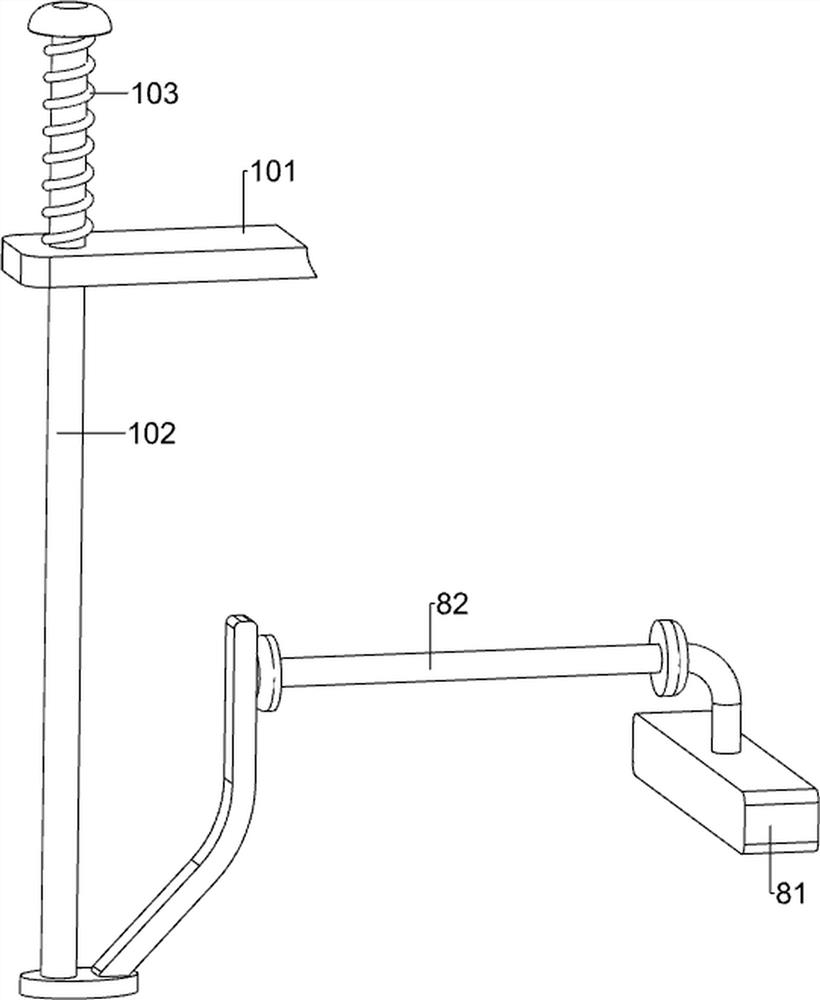

[0061] A kind of heat sink self-punching equipment for CPU heat sink, such as figure 1 As shown, it includes a first support base 1, a first support frame 2, a second support frame 3, a third connecting support frame 4, a discharge frame 5 and a punching mechanism 6, and the upper front side of the first support base 1 is provided with The first support frame 2, the left and right sides of the first support base 1 rear portion are symmetrically provided with the second support frame 3, the first support frame 2 rear portion is provided with a discharge frame 5, and the discharge frame 5 front and rear sides are connected with a third The supporting frame 4 is connected, the third supporting frame 4 is connected with the second supporting frame 3 , and the punching mechanism 6 is slidably provided on the first supporting frame 2 .

[0062] When people need to punch holes for the heat sink, they can use the heat sink self-punching equipment for the CPU heat sink. First, people p...

Embodiment 2

[0064] On the basis of Example 1, such as figure 2As shown, the punching mechanism 6 includes a punching device 61, a first spring 62 and a first round bar 63, and the sliding type is provided with a punching device 61 on the first support frame 2, and the punching device 61 and the first support frame 2 is connected with a first spring 62, and the first spring 62 is wound on the knife punching device 61, and a first round bar 63 is connected to the rear side of the top of the knife punching device 61.

[0065] First, people place the heat sink directly under the knife puncher 61, and then manually move the first round bar 63 downward, so that the knife puncher 61 moves downward, and the first spring 62 is compressed, which realizes punching the heat sink. Operation, when punching is not needed, the first round bar 63 is released, and the first spring 62 drives the puncher 61 to reset, so that the first round bar 63 resets.

Embodiment 3

[0067] On the basis of Example 2, such as Figure 3-8 As shown, it also includes a feeding mechanism 7, the feeding mechanism 7 includes a pusher 71, a push rod 72, a second spring 73 and a second round bar 74, and the first support frame 2 slides on the left side and is provided with a pusher. Material rod 72, pusher rod 72 rear portion is connected with pusher 71, is connected with second spring 73 between the first support frame 2 and pusher 71, and second spring 73 is wound on the pusher rod 72, pushes material The right side of the device 71 is provided with a second round bar 74 .

[0068] People manually move the push rod 72 forward, and the second spring 73 is compressed, so that the pusher 71 pushes the heat sink under the discharge frame 5 to move forward, so that the second round bar 74 moves forward, which realizes The effect of feeding, when feeding is completed, people unclamp push rod 72, and second spring 73 drives push rod 72 to reset, and push rod 72 drives ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com