Polymer powder compositions which can be redispersed in water

A technology for redispersing polymers and compositions, which can be used in fertilizer mixtures, soil protection, infrastructure engineering, etc., and can solve problems such as unevenness and separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

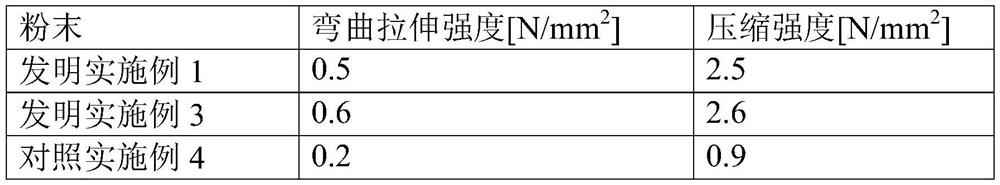

Examples

Embodiment 1

[0062] First 53 g of sodium sulfate were dissolved in 1350 g of water, then 420 g of a 20 wt % aqueous solution of polyvinyl alcohol with a Hoppler viscosity of 4 mPas and a degree of hydrolysis of 88 mol % (Mowiol 4-88 from Kuraray) and 360 g of a Hoppler viscosity of 13 mPas and an 11% by weight aqueous solution of polyvinyl alcohol with a degree of hydrolysis of 88 mol% (Mowiol 13-88 from Kuraray), and the mixture was stirred for 10 minutes.

[0063] 3.6 g of an acrylamide-acrylic acid copolymer powder (Flobond A30 from SNF) having 70% by weight of acrylamide and 30% by weight of acrylic acid were then added to the solution, and the mixture was stirred for 4 hours.

[0064] The result was a clear solution with a viscosity of 61 mPas (Brookfield BF20 at 23° C., spindle 1).

[0065] This solution is mixed with 3 kg of polyvinyl alcohol-stabilized vinyl acetate-ethylene copolymer dispersion (93 wt % vinyl acetate, 7 wt % ethylene, Tg=16° C.) with a solid content of 58 wt %, an...

Embodiment 3

[0075] 29.2kg solid content is 58wt% polyvinyl alcohol stabilized vinyl acetate-ethylene copolymer dispersion (93wt% vinyl acetate, 7wt% ethylene, Tg=16 ℃) with 9.1kg water, 3.6kg hope 20 wt% aqueous polyvinyl alcohol solution (Mowiol 4-88 from Kuraray) with a Lek viscosity of 4 mPas and a degree of hydrolysis of 88 mol % and 2.9 kg of an aqueous 11 wt % polyvinyl alcohol solution with a Hoppler viscosity of 13 mPas and a degree of hydrolysis of 88 mol % (from Kuraray Mowiol 13-88) for blending.

[0076] 112 g of an acrylamide-acrylic acid copolymer 30 wt% aqueous emulsion (Flobond Emulsion L33 from SNF) with 70 wt% acrylamide and 30 wt% acrylic acid were then added and the mixture was stirred for 2 hours. The result was a homogeneous mixture with a viscosity of 250 mPas (Brookfield BF20, SP1, at 23° C.).

[0077] The mixture is then sprayed using a two-fluid nozzle. The atomized components used were pre-air compressed to 4 bar. The formed droplets were simultaneously dried...

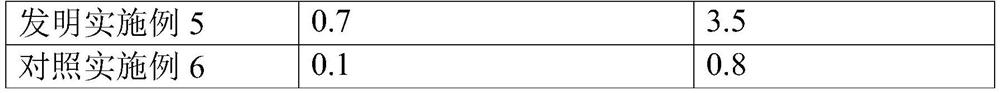

Embodiment 5

[0083] The procedure of Inventive Example 3 was repeated, except that instead of 3.6 kg of a 20 wt% aqueous solution of polyvinyl alcohol (Mowiol 4-88 from Kuraray) with a Hoppler viscosity of 4 mPas and a degree of hydrolysis of 88 mol%, an equal amount of 20% by weight aqueous solution of hydrolyzed vinyl acetate-VeoVa10-vinylsulfonate copolymer.

[0084] The blocking stability of the obtained powder was 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com