Offline determination system and method for content of dissolved hydrogen in pressurized water reactor primary loop coolant

A technology for measuring systems and coolants, which is used in testing water, reactors, nuclear reactor monitoring, etc., can solve the problems that offline hydrogen meters cannot accurately measure dissolved hydrogen concentration and offline hydrogen meters Mobile testing, the effect of avoiding corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

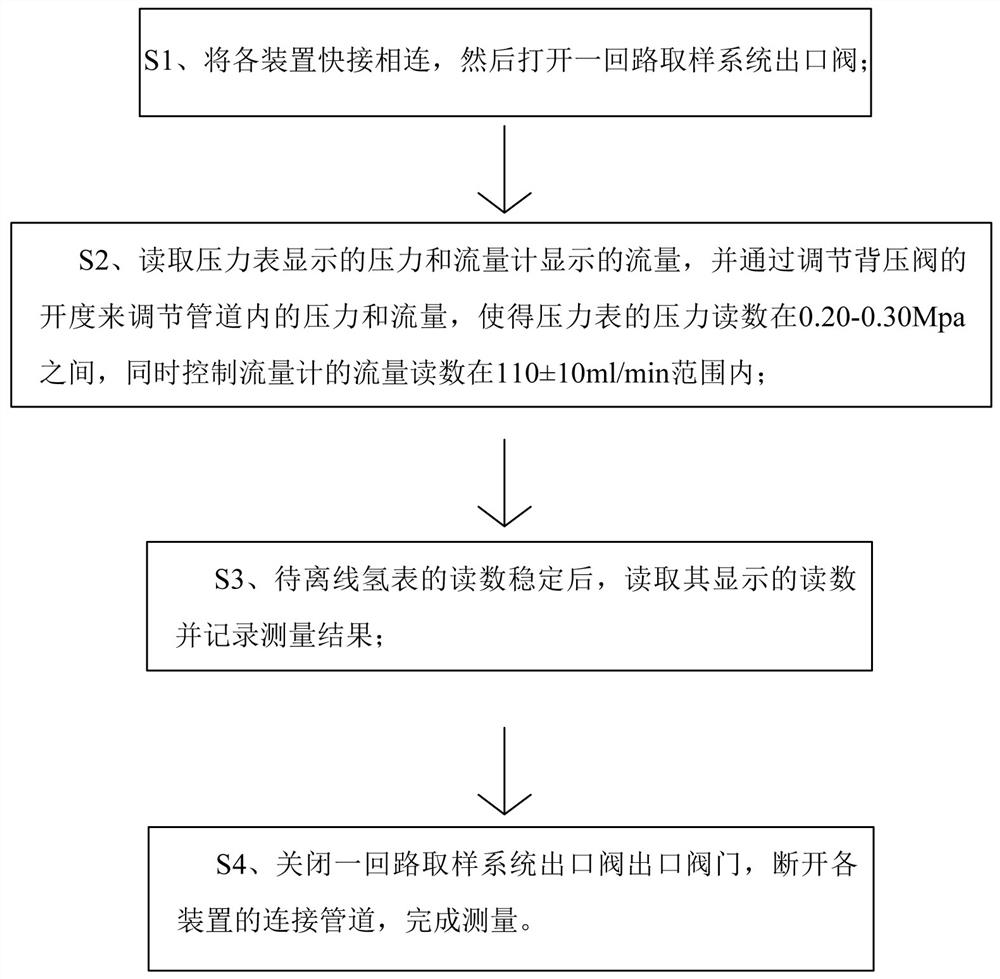

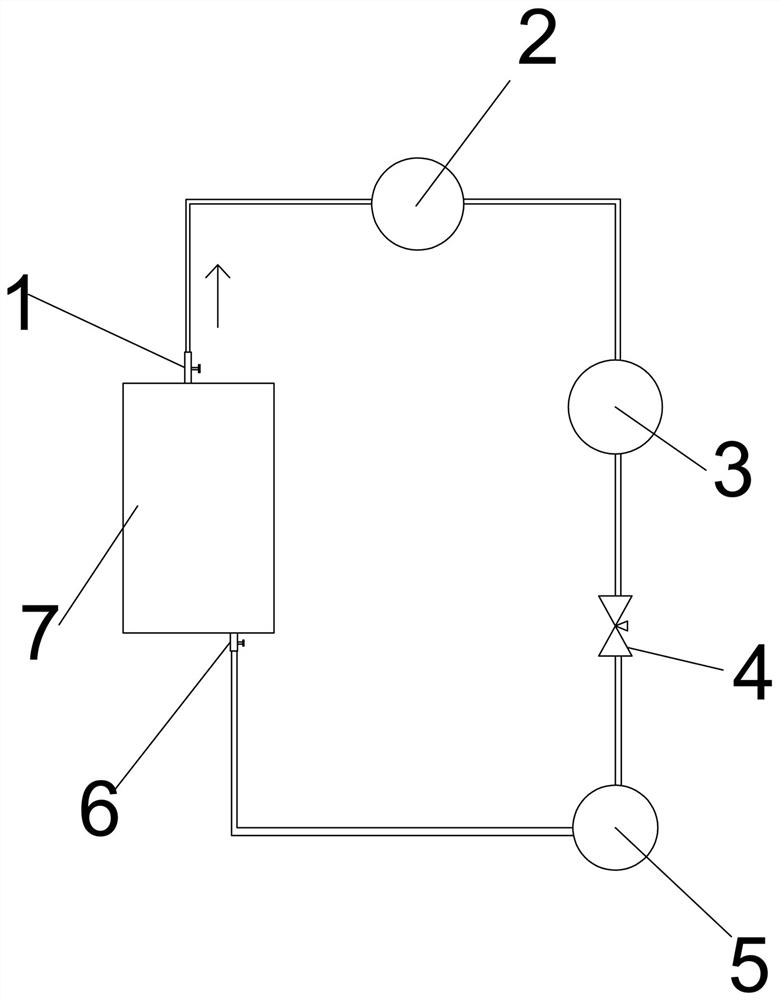

[0041] Quickly connect each device, and then open the outlet valve 1 of the primary loop sampling system;

[0042] Read the pressure displayed by pressure gauge 2 and the flow rate displayed by flowmeter 5, and adjust the pressure and flow in the pipeline by adjusting the opening of back pressure valve 4, so that the pressure reading of pressure gauge 2 is 0.20Mpa, and at the same time control the flowmeter The flow reading of 5 is 120ml / min;

[0043] After the reading of the off-line hydrogen meter 3 is stable, read the displayed reading and record the measurement result;

[0044] Close the outlet valve 1 of the primary loop sampling system, disconnect the connecting pipes of each device, and complete the measurement.

Embodiment 2

[0046] Quickly connect each device, and then open the outlet valve 1 of the primary loop sampling system;

[0047] Read the pressure displayed by pressure gauge 2 and the flow rate displayed by flowmeter 5, and adjust the pressure and flow in the pipeline by adjusting the opening of back pressure valve 4, so that the pressure reading of pressure gauge 2 is 0.22Mpa, and at the same time control the flowmeter The flow reading of 5 is 115ml / min;

[0048] After the reading of the off-line hydrogen meter 3 is stable, read the displayed reading and record the measurement result;

[0049] Close the outlet valve 1 of the primary loop sampling system, disconnect the connecting pipes of each device, and complete the measurement.

Embodiment 3

[0051] Quickly connect each device, and then open the outlet valve 1 of the primary loop sampling system;

[0052] Read the pressure displayed by pressure gauge 2 and the flow rate displayed by flowmeter 5, and adjust the pressure and flow in the pipeline by adjusting the opening of back pressure valve 4, so that the pressure reading of pressure gauge 2 is 0.24Mpa, and control the flowmeter at the same time The flow reading of 5 is 110ml / min;

[0053] After the reading of the off-line hydrogen meter 3 is stable, read the displayed reading and record the measurement result;

[0054] Close the outlet valve 1 of the primary loop sampling system, disconnect the connecting pipes of each device, and complete the measurement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com