High heat-resistant and high-toughness polyester, polyester product, preparation method and application thereof

A high toughness, high heat resistance technology, used in polyester, high heat resistance and high toughness polyester, polyester products and their preparation fields, can solve problems such as insufficient heat resistance, achieve high structural rigidity, high molecular weight, improve glass Effect of transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] One aspect of the embodiments of the present invention provides a method for preparing a class of high heat-resistant high-toughness polyester, which includes:

[0035] reacting the first mixed reaction system comprising bishydroxyethoxy polycyclic aromatic hydrocarbons, dibasic acids or esterified products thereof, dibasic alcohols, esterification or transesterification catalysts at 160-240°C to obtain intermediate products, wherein the dibasic acids The basic acid is any one or a combination of two or more of thiophenedicarboxylic acid, furandicarboxylic acid, and terephthalic acid;

[0036] reacting the second mixed reaction system comprising the intermediate product, the polycondensation catalyst and the stabilizer at 220-290°C under vacuum conditions to obtain a high heat-resistant and high-toughness polyester;

[0037] The bishydroxyethoxy polycyclic aromatic hydrocarbon has a structure as shown in any one of formula (1) to formula (9):

[0038] .

[0039] In ...

Embodiment 1

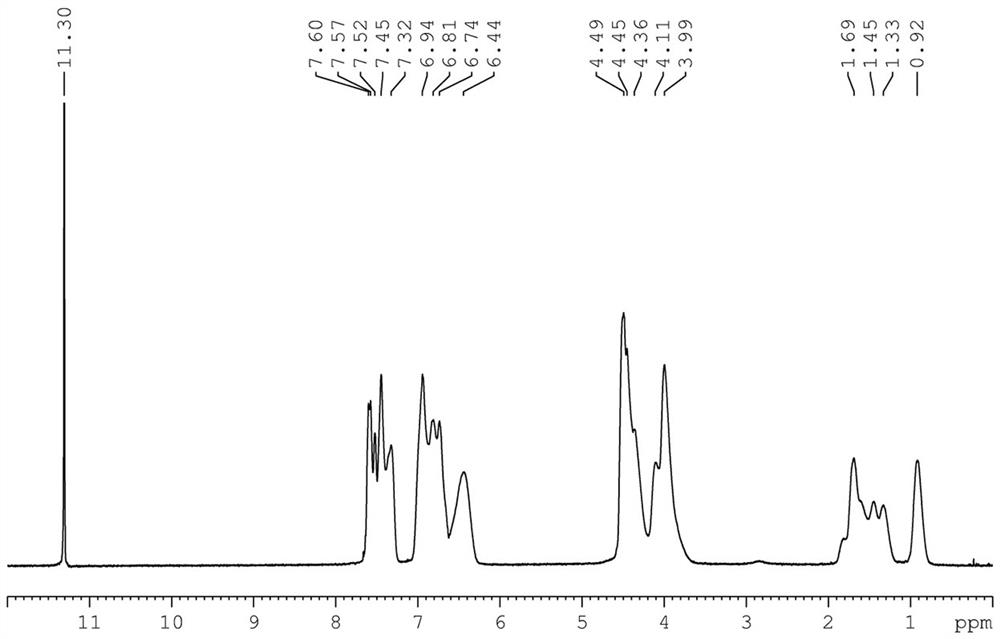

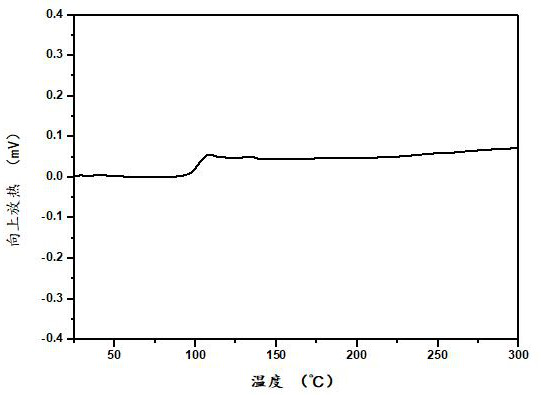

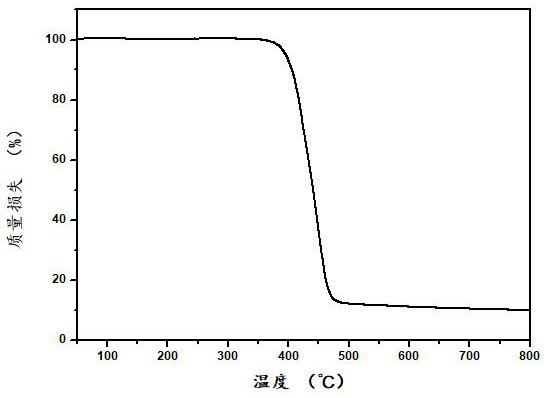

[0107] Dimethyl 2,5-thiophenedicarboxylate, bishydroxyethoxy polycyclic aromatic hydrocarbons (formula (2)), ethylene glycol, and 1,4-cyclohexanedimethanol in a molar ratio of 1:0.20:2.1:0.2 Add it into the reactor, then add the transesterification catalyst anhydrous zinc acetate with a molar weight of 0.8‰ of dimethyl 2,5-thiophenedicarboxylate, under the condition of nitrogen protection, gradually raise the temperature to 180°C for esterification, react for 4.0h, and then Add polycondensation catalyst antimony trioxide with a molar mass of dimethyl 2,5-thiophenedicarboxylate of 1.0‰, and stabilizer trimethyl phosphate with a molar weight of 1.0‰, gradually raise the temperature to 230°C, gradually reduce the vacuum degree to 50Pa, and react for 3.5 hours. The poly-2,5-thiophenedicarboxylic acid bishydroxyethoxy polycyclic aromatic hydrocarbon glycol 1,4-cyclohexanedimethanol copolyester is obtained, the structure of which is shown in formula (35). The intrinsic viscosity of ...

Embodiment 2

[0111] Add dimethyl 2,5-thiophenedicarboxylate, bishydroxyethoxy polycyclic aromatic hydrocarbon (formula (2)), and ethylene glycol into the reactor at a molar ratio of 1:0.1:2.1, and then add 2,5- Anhydrous zinc acetate with a molar mass of dimethyl thiophenedicarboxylate of 0.8‰, under the condition of nitrogen protection, gradually raise the temperature to 180°C for esterification, react for 3.5 hours, then add dimethyl 2,5-thiophenedicarboxylic acid with a molar mass of 0.8‰ antimony trioxide, 1.0‰ stabilizer trimethyl phosphate, gradually increase the temperature to 220°C, gradually reduce the vacuum degree to 20Pa, and react for 3.0h to obtain poly-2,5-thiophenedicarboxylic acid bishydroxyethoxy polycyclic aromatic hydrocarbons Ethylene glycol copolyester, the structure is as formula (36), the intrinsic viscosity of the copolyester is 0.76 dL / g, the glass transition temperature is 94 ℃, the cut-off is 700nm, the visible light transmittance is 90%, and the elongation at br...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com