Preparation method of aluminum phosphate super-hydrophilic film

A kind of aluminum phosphate, super-hydrophilic technology, applied in the direction of energy wastewater treatment, coating, etc., can solve the problems that have not been reported in the research, and achieve the effect of good durability and good transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The invention provides a kind of preparation method of aluminum phosphate superhydrophilic film, comprises the following steps:

[0030] S1. Configure aluminum phosphate sol, weigh 0.2205g of aluminum lactate and dissolve it in 30ml of water, add 1ml of 0.075mol / L phosphoric acid, 1.57g of citric acid, and 0.465g of polyethylene glycol to obtain aluminum phosphate sol;

[0031] S2, aging the aluminum phosphate sol for 24 hours at room temperature;

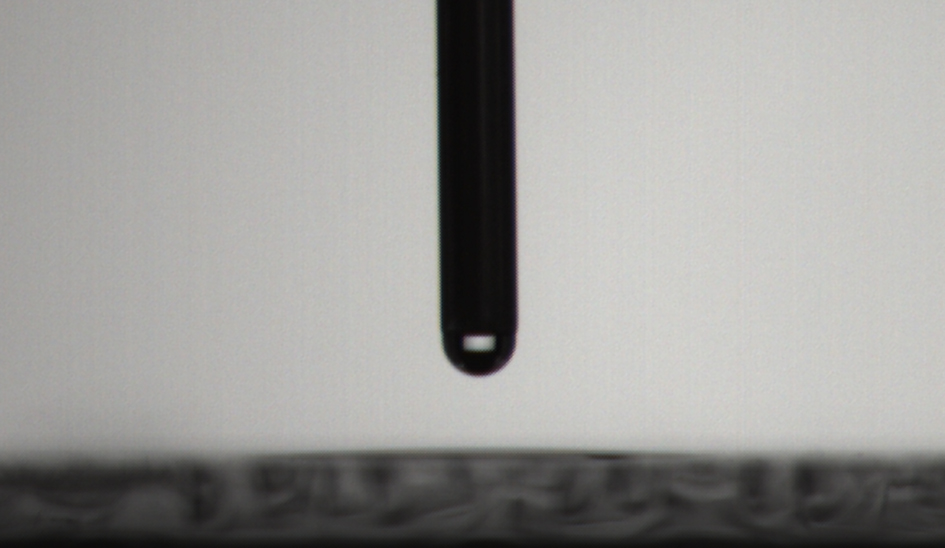

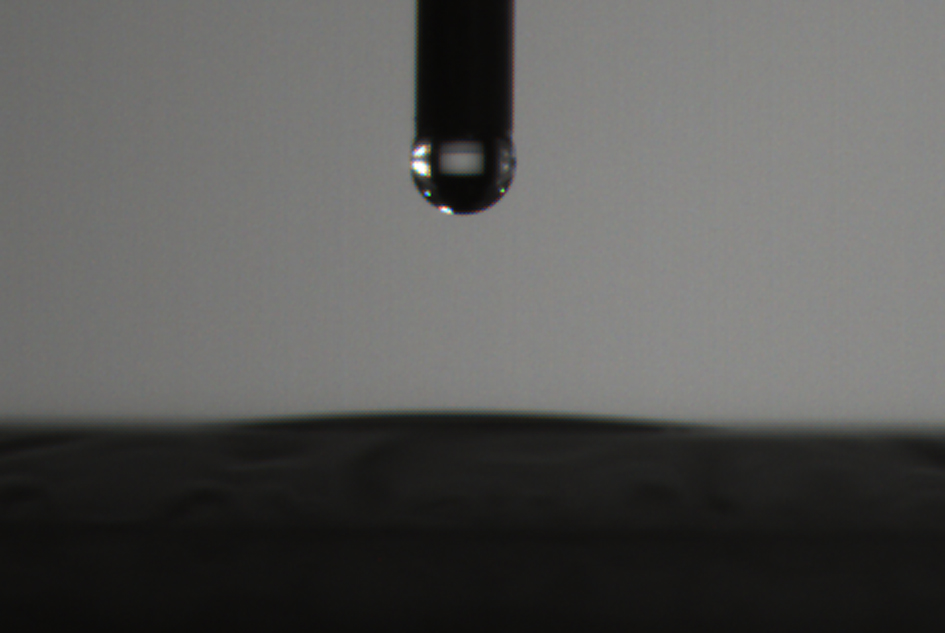

[0032] S3, using the aged aluminum phosphate sol to plate an aluminum phosphate precursor film on the surface of the glass substrate;

[0033] S4. Preheating the aluminum phosphate precursor film, the preheating temperature is 100°C, and the preheating time is 30min;

[0034] S5, heat treatment the preheated aluminum phosphate precursor film at a heating temperature of 500° C. for 30 minutes, and naturally cool to room temperature to obtain an aluminum phosphate superhydrophilic film.

[0035] The obtained aluminum phospha...

Embodiment 2

[0037] The invention provides a kind of preparation method of aluminum phosphate superhydrophilic film, comprises the following steps:

[0038] S1. Configure aluminum phosphate sol, weigh 1.532g of aluminum isopropoxide and dissolve it in 30ml of water, add 1ml of 0.075mol / L phosphoric acid, 1.57g of citric acid, and 4.65g of polyethylene glycol to obtain aluminum phosphate sol;

[0039] S2. Aging the aluminum phosphate sol for 6 hours at room temperature;

[0040] S3, using the aged aluminum phosphate sol to plate an aluminum phosphate precursor film on the surface of the glass substrate;

[0041] S4. Perform preheating treatment on the aluminum phosphate precursor film, the preheating temperature is 100°C, and the preheating time is 1h;

[0042] S5. Heat the preheated aluminum phosphate precursor film at a heating temperature of 500° C. for 1 hour, and naturally cool to room temperature to obtain an aluminum phosphate superhydrophilic film.

[0043] The obtained aluminum p...

Embodiment 3

[0045] The invention provides a kind of preparation method of aluminum phosphate superhydrophilic film, comprises the following steps:

[0046] S1. Configure aluminum phosphate sol, weigh 0.0441g of aluminum lactate and dissolve it in 30ml of water, add 0.2ml of 0.075mol / L phosphoric acid, 1.57g of citric acid, and 0.465g of polyethylene glycol to obtain aluminum phosphate sol;

[0047] S2. Aging the aluminum phosphate sol for 0.5h at room temperature;

[0048] S3, drying the aged aluminum phosphate sol to obtain aluminum phosphate gel;

[0049] S4. Preheating the aluminum phosphate gel, the preheating temperature is 90°C, and the preheating time is 5h;

[0050] S5. Heat the preheated aluminum phosphate precursor film at a heating temperature of 500° C. for 1 hour, and naturally cool to room temperature to obtain an aluminum phosphate superhydrophilic film.

[0051] The obtained aluminum phosphate superhydrophilic film was tested for hydrophilicity, and the contact angle was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com