Welding deformation control method and device for gas turbine flame tube rectifying ring assembly

A gas turbine, welding deformation technology, applied in the direction of auxiliary equipment, welding equipment, welding equipment, etc., can solve the problems of large deviation of cross-sectional area, poor coaxiality, position degree of horseshoe-shaped plate column exceeding the design requirements, etc., and achieve high dimensional consistency , Strong operability and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0039] The basic train of thought of the welding deformation control method of the gas turbine flame cylinder rectifying ring assembly in the present invention is:

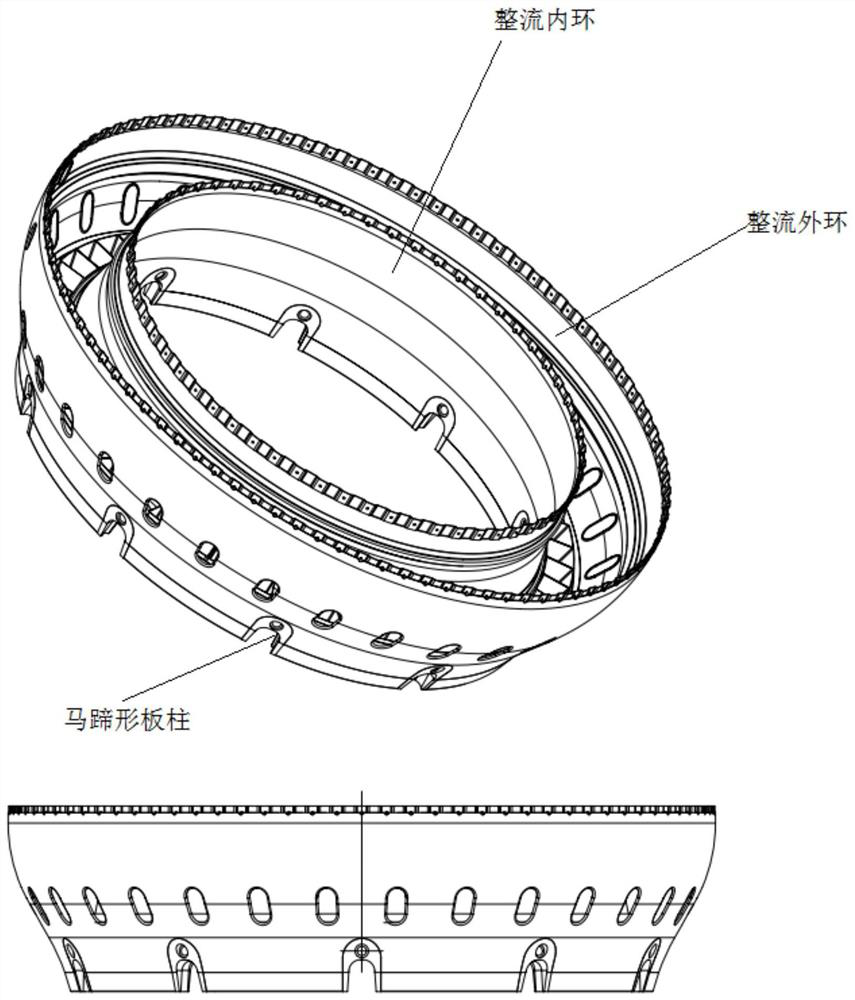

[0040] (1) Weld the 10 horseshoe-shaped connecting plate columns of the rectification outer ring and the rectification inner ring to form a cavity with a specific cross-sectional area of the flow channel (such as figure 1 shown).

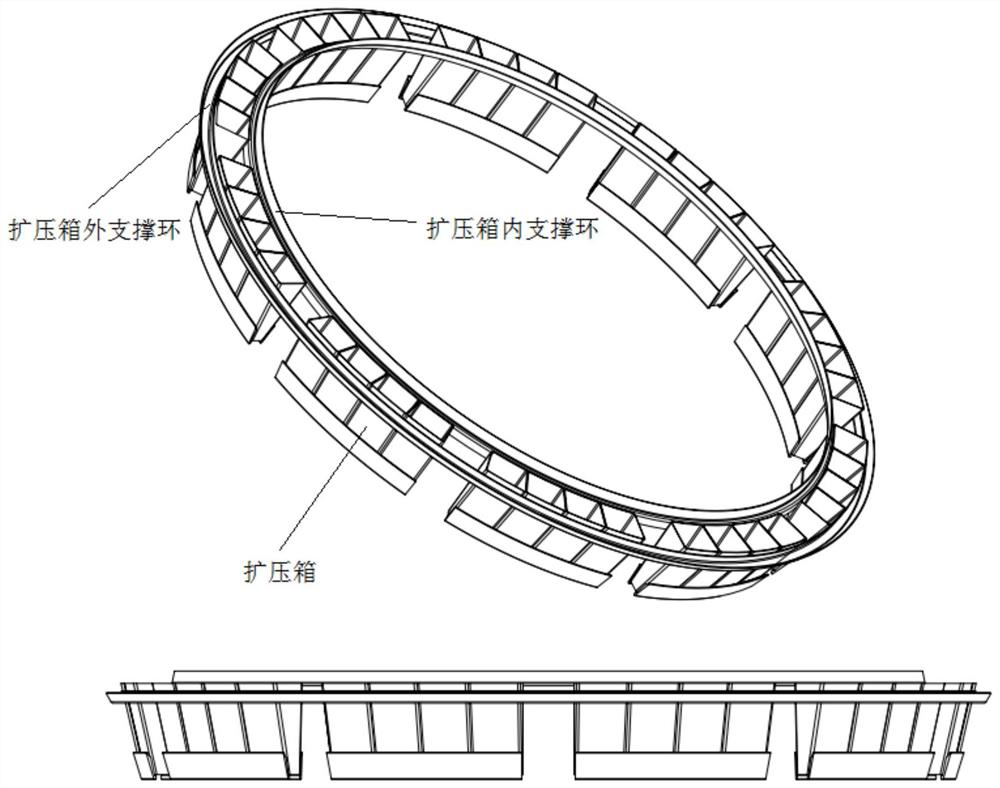

[0041] (2) Group the diffuser boxes according to the assembly rules, and the grouped diffuser boxes are respectively welded with the inner support ring of the diffuser box and the outer support ring of the diffuser box, so as to complete the welding of 40 diffuser boxes (such as figure 2 shown)

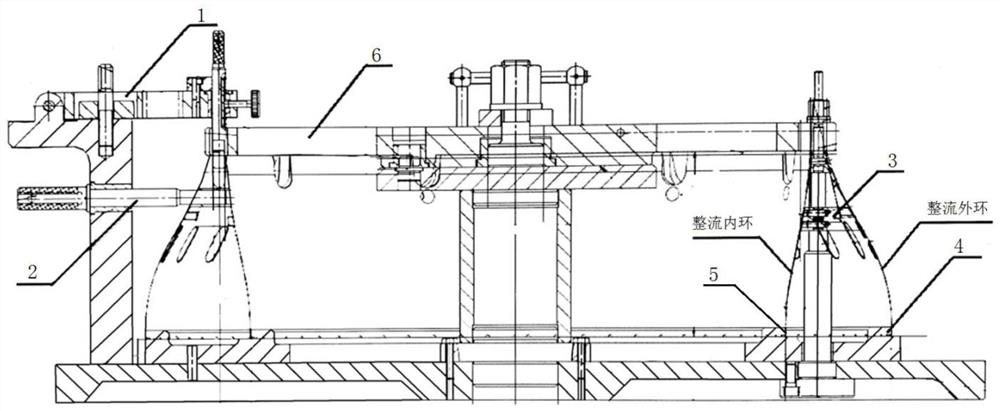

[0042] (3) Put the 40 diffuser box assemblies in step (2) into the cavity body in step (1), and complete the assembly and weldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com