A Debugging Method for Bonding of Annular Aspheric Mirror

A debugging method and aspheric technology, applied in the directions of instruments, installation, optics, etc., can solve the problems of poor consistency, difficult to effectively control the parallelism and coaxiality of annular aspherical mirrors, and achieve the effect of controlling coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

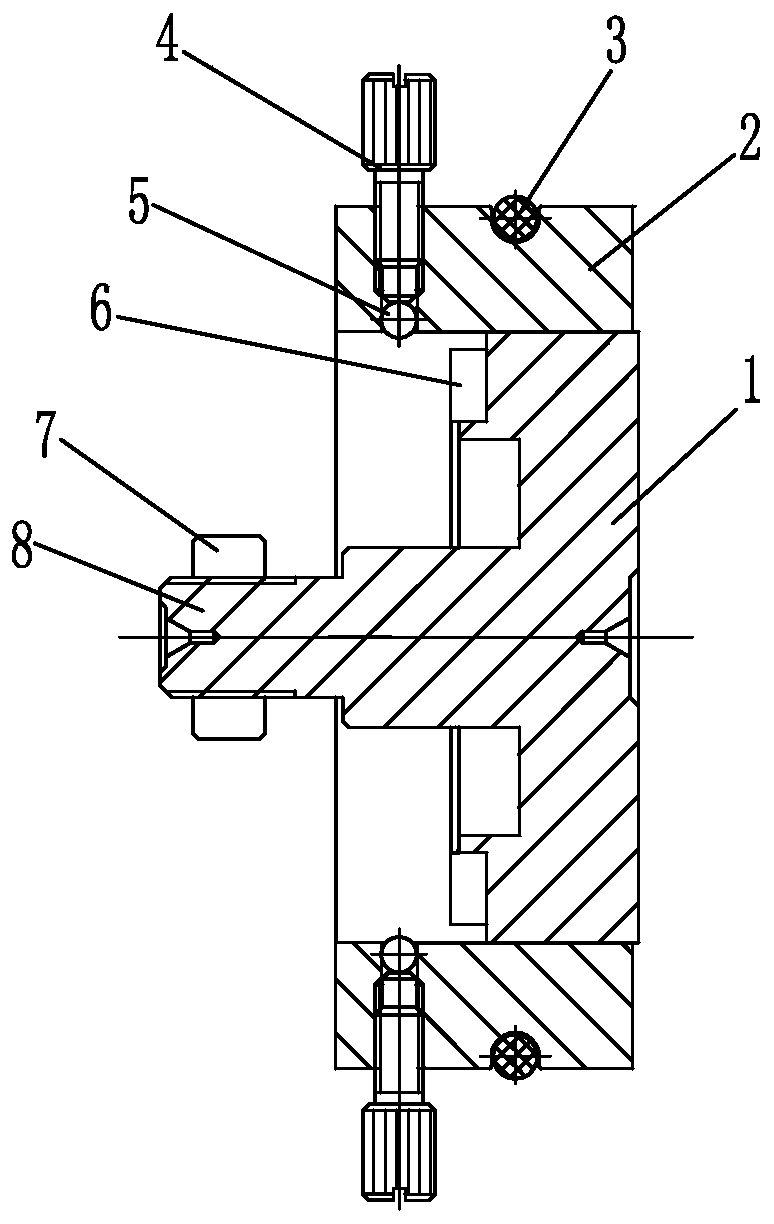

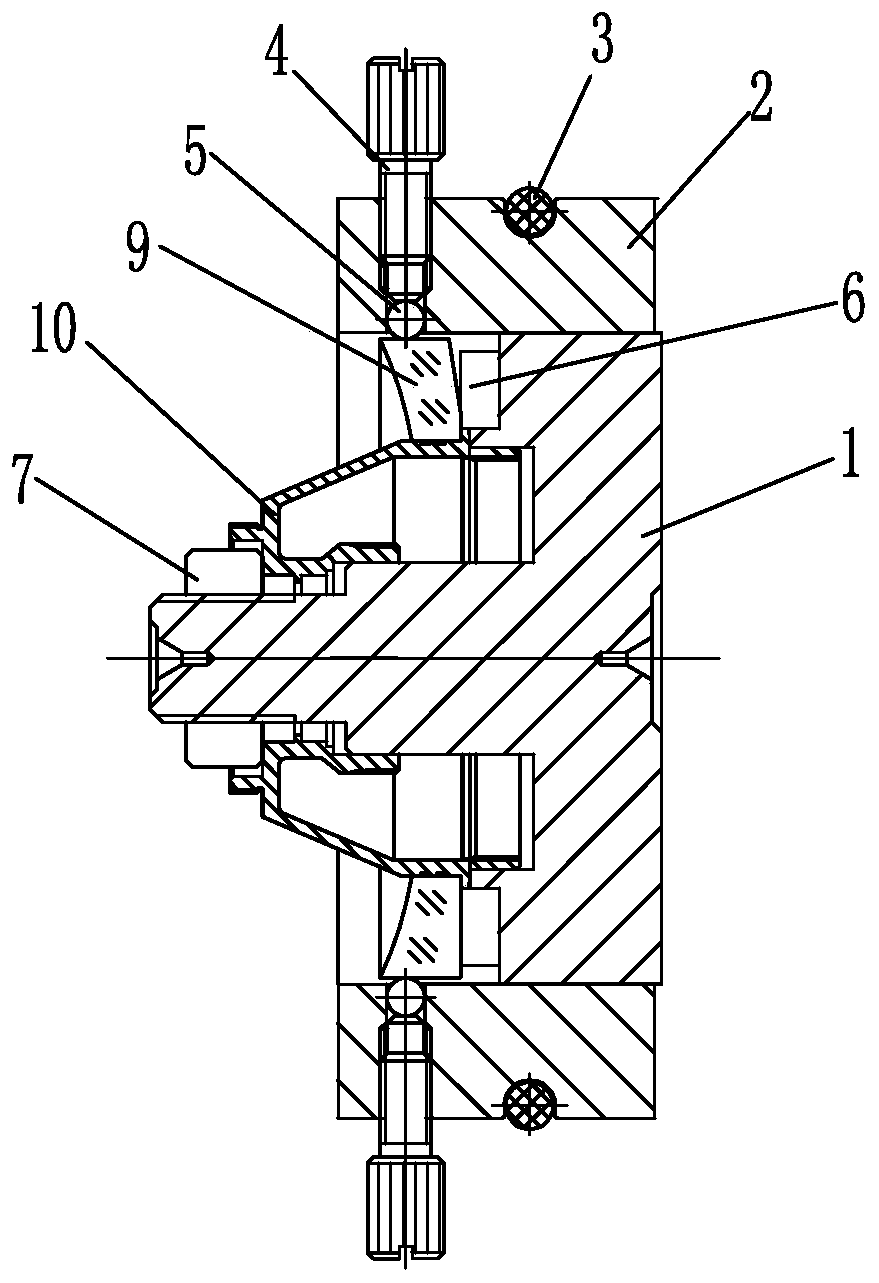

[0014] Such as Figure 1 to Figure 3 As shown, the debugging method of the cementation of a ring aspheric mirror in the present invention includes the following six steps.

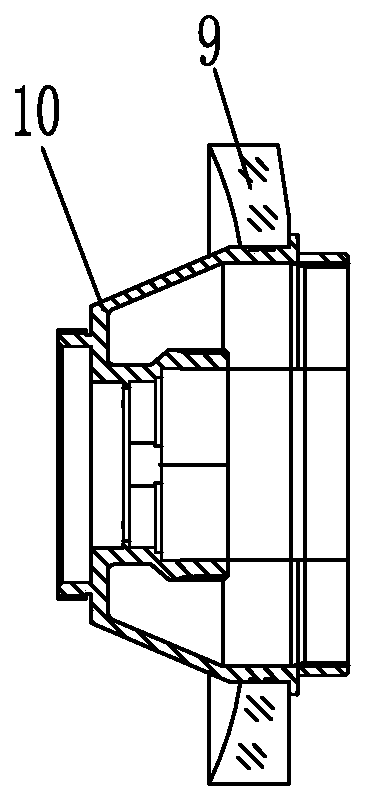

[0015] (1) Set up the stereotyped adjustment tooling, which includes the base 1, the support ring 2, the washer 6, the clamping device and the fastening belt 3, and the positioning column 8 protruding from the center hole of the positioning mirror holder 10 in the middle of the base 1, and the positioning column The end of 8 is provided with an external thread, the support ring 2 is positioned outside the outer wall of the base 1, and the outer wall of the support ring 2 is evenly arranged with a plurality of through-holes on the same circumference. In this embodiment, a total of four through-holes are provided. The distance between the adjacent through holes is 90 degrees, the gasket 6 is placed on the inner surface of the base 1, and the tightening device is positioned in the through hole on the outer wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com