Evaporation-fusion composite laser polishing method capable of realizing peak clipping and then valley filling of metal surface

A metal surface, laser polishing technology, used in laser welding equipment, metal processing equipment, welding equipment, etc., can solve problems affecting metal surface performance, energy input, etc., and achieve the effect of reducing heat input, reducing times, and high polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 metal surface single continuous laser polishing method

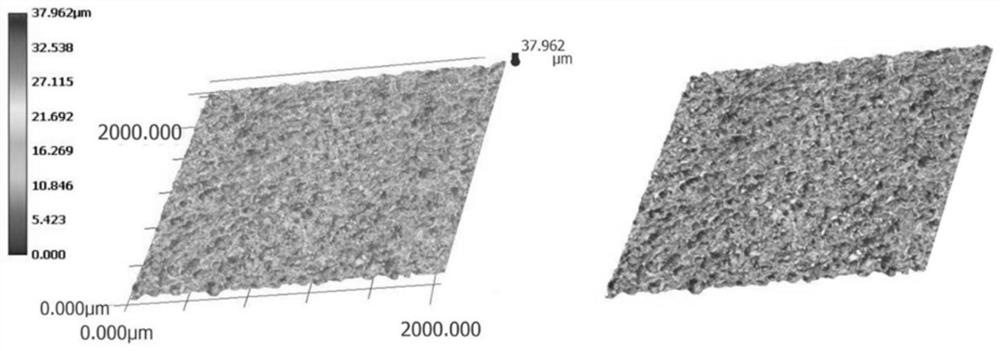

[0031] select as figure 1 The size of the 316L stainless steel block shown is 100mm×60mm×10mm, and its surface 1 is a large roughness surface cut by a model DK77-30 electric discharge CNC wire cutting machine, which is cleaned, dried and pretreated. Surface characterization, characterization results such as figure 2 shown.

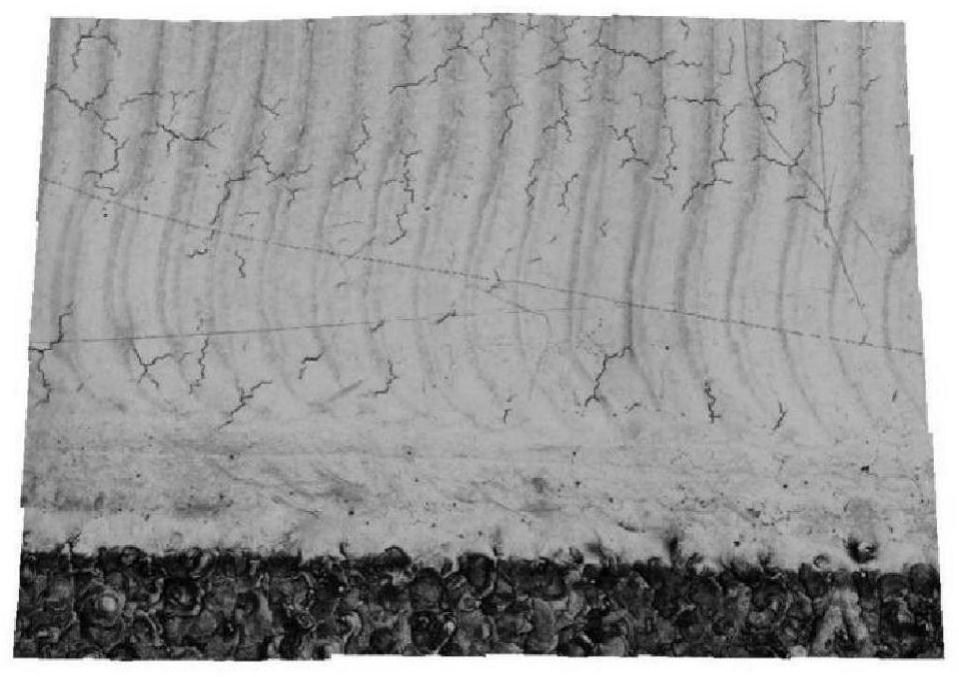

[0032] Place the workpiece in an atmosphere protection box, perform single continuous laser polishing, and set continuous laser parameters: laser wavelength 1064nm, laser power 500W, scanning speed 500mm / s, scanning area 10mm×10mm, scanning line spacing 0.04mm, scanning times 6 times , the scanning and filling method is horizontal scanning from left to right, and vertical stacking from top to bottom. The overlapping rate of vertical stacking is 67%. The surface characterization results are as follows image 3 As shown, there are many microscopic thermal cracks on the surface a...

Embodiment 2

[0033] Example 2 Evaporation-melting composite laser polishing method of first cutting peaks and then filling valleys on the metal surface

[0034] select as figure 1 The size of the 316L stainless steel block shown is 100mm×60mm×10mm, and its surface 1 is a large roughness surface cut by a model DK77-30 electric discharge CNC wire cutting machine, which is cleaned, dried and pretreated. Surface characterization, characterization results such as figure 2 shown.

[0035] Put the workpiece in the atmosphere protection box, perform evaporation-melting composite laser polishing, set the pulse laser parameters: laser wavelength 1064nm, laser power 100W, scanning speed 1000mm / s, repetition frequency 500kHz, pulse width 10ns, scanning area 10mm×10mm , the scanning line spacing is 0.05mm, and the number of scanning is 8 times. The scanning and filling method is horizontal scanning from left to right and vertical stacking from top to bottom. The surface characterization results of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com