Device for peeling dry towel gourds through friction

A dry loofah and belt technology is applied to fruit de-pitting device, vegetable or fruit peeling, food processing and other directions, which can solve the problems of low efficiency, high work intensity, cumbersome steps, etc., so as to reduce work intensity and improve work efficiency. , the effect of rapid peeling and seed removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

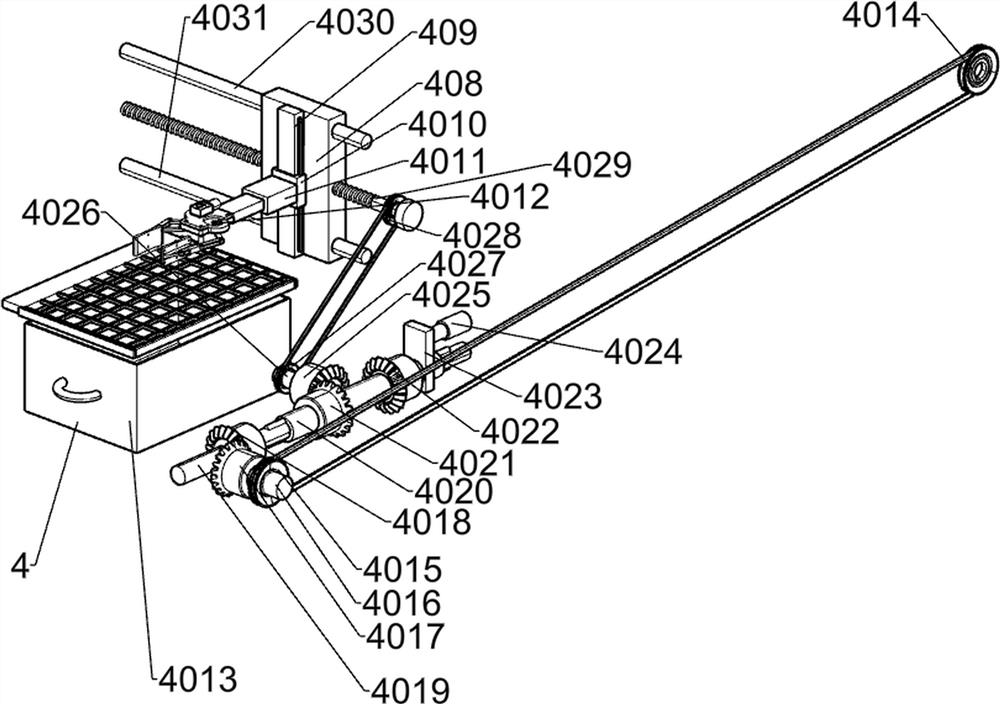

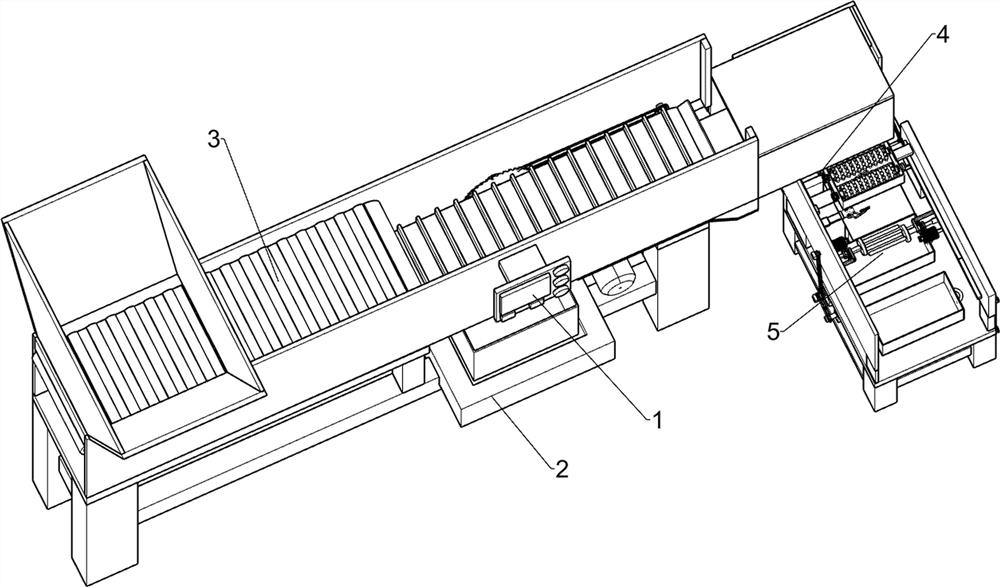

[0030] A device for peeling dry loofah by friction, such as Figure 1-8 Shown, include control panel 1, support frame 2, cutting mechanism 3, seed removal mechanism 4 and peeling mechanism 5; Control panel 1 is connected with support frame 2; Support frame 2 is connected with cutting mechanism 3; Support frame 2 and The seed removal mechanism 4 is connected; the support frame 2 is connected with the peeling mechanism 5 ; the cutting mechanism 3 is connected with the seed removal mechanism 4 ; the seed removal mechanism 4 is connected with the peeling mechanism 5 .

[0031] Working principle: When preparing for work, fix the device in a horizontal position, put the dry loofah into the cutting mechanism 3, turn on the power, and then operate the control panel 1 on the support frame 2 to start operation, and the cutting mechanism 3 will cut the dried loofah The two ends are cut off, and then transported from the cutting mechanism 3 to the seed removal mechanism 4 for seed removal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com