Airtight terminal

An air-tight terminal and air-tight ground technology, used in capacitor terminals, electrical components, fixed capacitor terminals, etc., can solve problems such as damage, air-tight damage, and lightweight problems, achieve simple air-tight sealing, and simplify assembly processes. , The effect of preventing the air tightness of the container

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

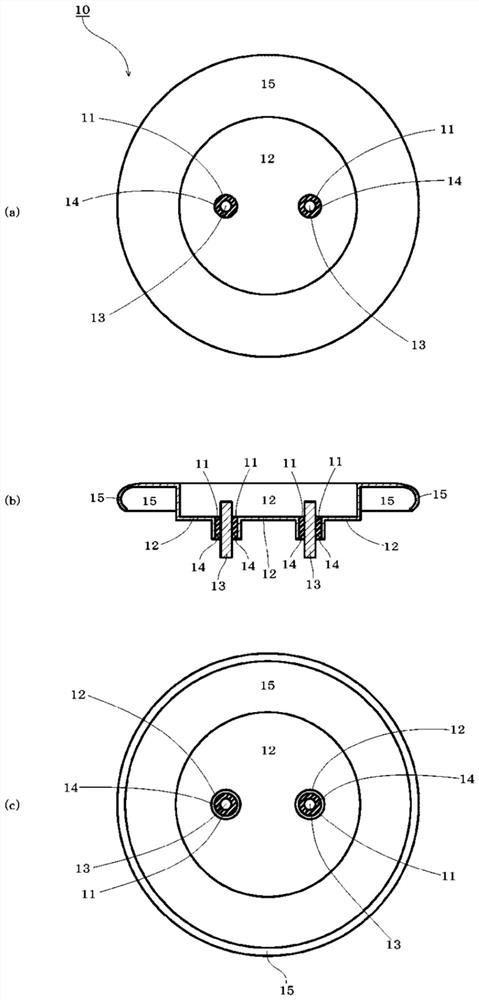

[0037] Such as figure 1 As shown, the airtight terminal 10 according to Embodiment 1 of the present invention includes: a cover body 12, which is formed of an aluminum plate-shaped metal sheet, and the surface of the plate is extended in a cylindrical shape, and the end surface is provided as an opening. The cover body There are two through holes 11; aluminum leads 13 that pass through the through holes 11 of the cover 12; and an insulating material 14 that hermetically seals the leads 13 and the cover 12 and is formed of insulating glass, and the cover 12 is along the Its edge portion has an engaging portion 15 formed by a curled portion for double seaming sealing with the tank shell. The airtight terminal 10 of the present invention can also be configured such that when the cover 12 and the lead wire 13 are directly glass-sealed, the thickness of the sealing portion contacting the insulating glass is greater than that of the other plate surface portions of the cover 12, ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com