Electric pile heating device and fuel cell system hierarchical control method

A heating device and stack technology, which is applied to fuel cells, circuits, electrical components, etc., can solve the problems of slow heating speed of stacks and large heating consumption at startup.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

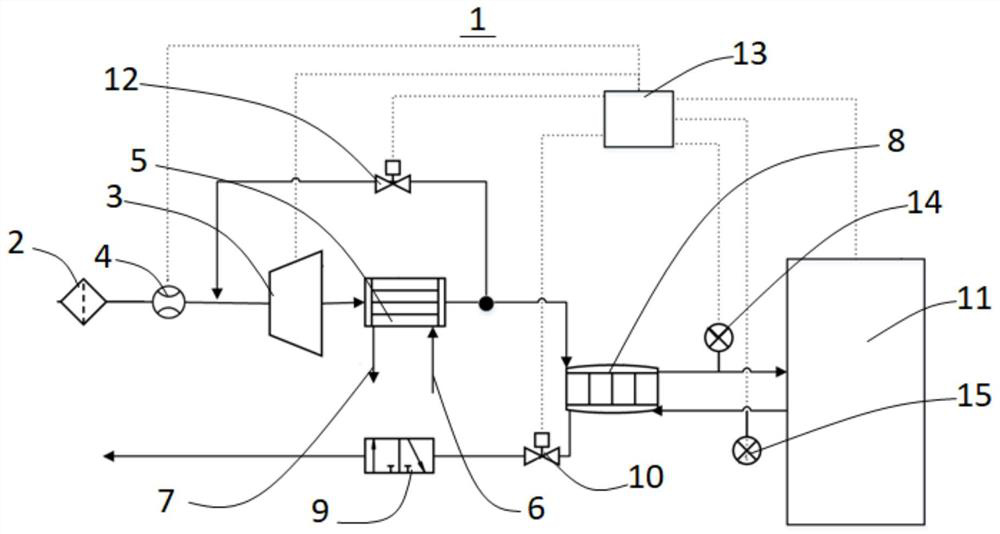

[0061] Please refer to figure 1 , the application provides a stack heating device 1, including an air filter 2, the inlet pipe of the air compressor 3 is connected to the outlet pipe of the air filter 2 through the air flow meter 4, and the inlet pipe of the intercooler 5 is connected to the air The outlet pipe of the compressor 3, and the inlet cooling pipe 6 and the outlet cooling pipe 7 are respectively connected to the intercooler 5; the dry air side inlet of the humidifier 8 is connected to the first outlet pipe of the intercooler 5, and the humidifier The wet air side outlet of 8 is connected to the mixer 9 through the back pressure valve 10; at the same time, the air inlet of the stack 11 is connected to the dry air side outlet of the humidifier 8, and the air outlet is connected to the humid air of the humidifier 8 side inlet; the inlet pipe of the preheating valve 12 is connected to the second outlet pipe of the intercooler 5, and the outlet pipe is connected to the i...

no. 2 example

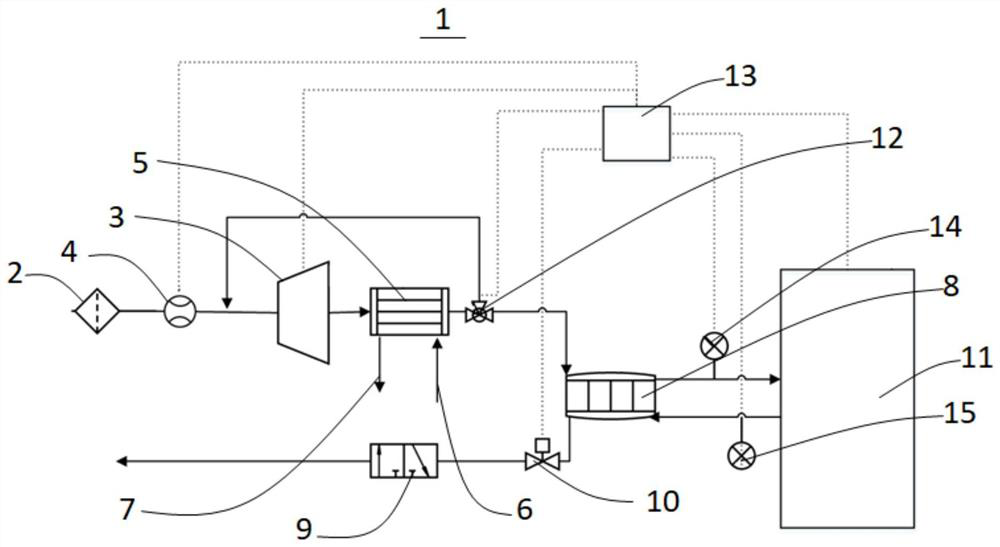

[0080] Please refer to figure 2 , the application provides a stack heating device 1, including an air filter 2; the inlet pipe of the air compressor 3 is connected to the outlet pipe of the air filter 2 through an air flow meter 4; the inlet pipe of the intercooler 5 is connected to The outlet pipe of the air compressor 3, and the inlet cooling pipe 6 and the outlet cooling pipe 7 are respectively connected to the intercooler 5; the inlet pipe of the preheating valve 12 is connected to the outlet pipe of the intercooler 5, and the second outlet pipe is connected to The air inlet pipe of the air compressor 3; the dry air side inlet of the humidifier 8 is connected to the first outlet pipe of the preheating valve 12, and the wet air side outlet of the humidifier 8 is connected to the mixed air through the back pressure valve 10. Discharge device 9; The air inlet of stack 11 is connected to the dry air side outlet of humidifier 8, and the air outlet is connected to the wet air s...

no. 3 example

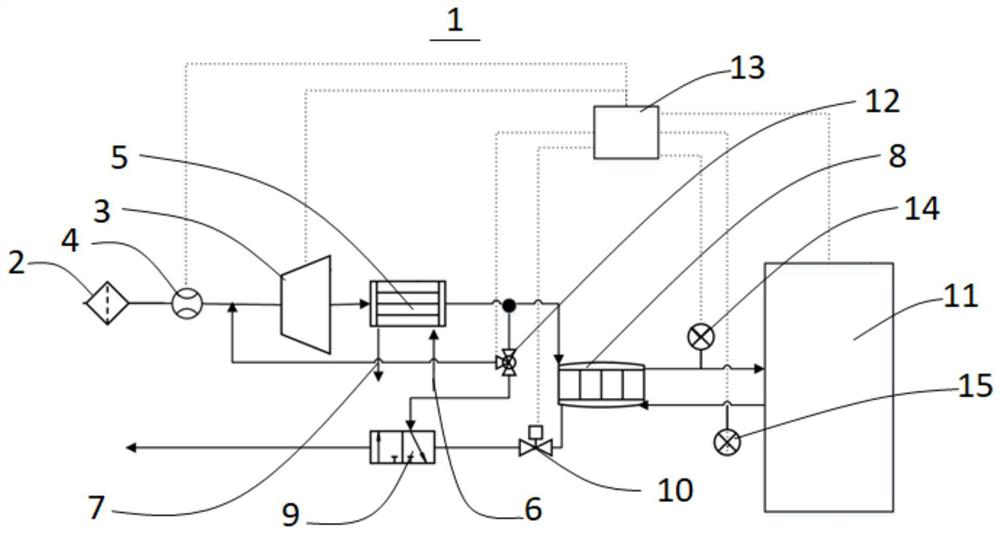

[0098] Please refer to image 3 , the application provides a stack heating device 1, which mainly includes an air filter 2; the air intake inlet pipe of the air compressor 3 is connected to the outlet pipe of the air filter 2 through an air flow meter 4; the inlet pipe of the intercooler 5 Connected to the outlet pipe of the air compressor 3, and the intercooler 5 is respectively connected to the inlet cooling pipe 6 and the outlet cooling pipe 7; the dry air side inlet of the humidifier 8 is connected to the first outlet pipe of the intercooler 5; Preheat valve 12, the inlet pipe of preheat valve 12 is connected to the second outlet pipe of intercooler 5, and the first outlet pipe is connected to the intake inlet pipe of air compressor 3; the humid air side outlet of humidifier 8 It is connected to the mixer 9 through the back pressure valve 10, and the second outlet pipe of the preheating valve 12 is connected to the mixer 9; the air inlet of the stack 11 is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com