Equipment intelligent early warning method based on multiple-input-multiple-output ResNet

A multi-output, multi-input technology, applied in the field of equipment failure early warning, can solve the problems of increased training set loss, low application in the industrial field, and few solutions, and achieve the goal of eliminating dimensional differences, facilitating incremental learning, and improving efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

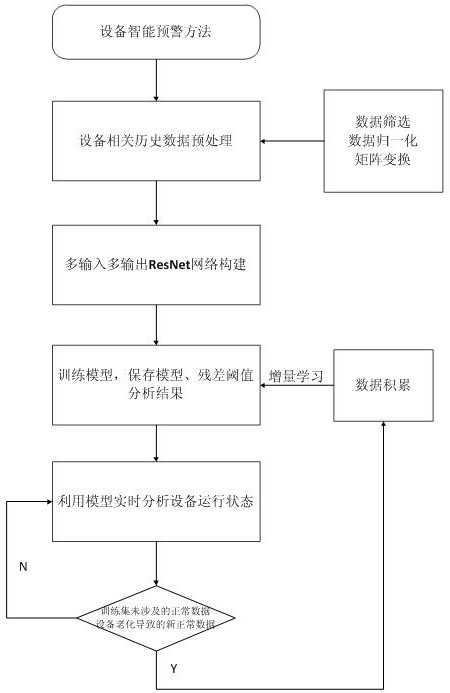

[0059] A method for intelligent early warning of equipment based on multiple-input multiple-output ResNet, comprising the following steps:

[0060] Step 1: Select historical data related to equipment and perform preprocessing;

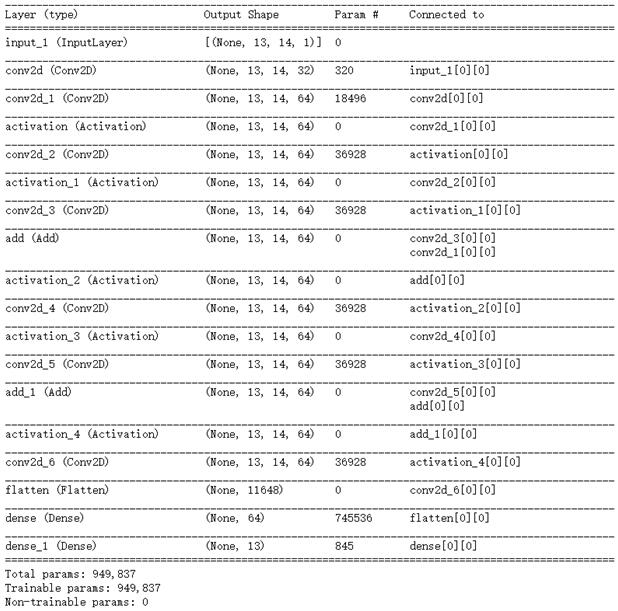

[0061] Step 2: Construct a multi-input multi-output ResNet network;

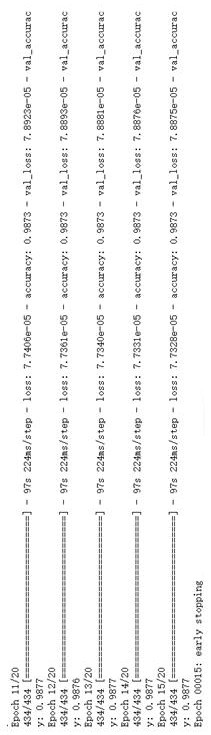

[0062] Step 3: Use the preprocessed device-related historical data to train the multi-input multi-output ResNet network to obtain an intelligent early warning model, and analyze the training results to obtain the residual threshold;

[0063] Step 4: Obtain real-time data related to the equipment, use the intelligent early warning model to calculate the predicted value, and judge the operating status of the equipment according to the residual threshold.

Embodiment 2

[0065] According to the multi-input multi-output ResNet network-based device intelligent early warning method described in Embodiment 1, the specific process of the first step is as follows:

[0066] (1) Extract historical data for a period of time from the real-time database, which includes measuring point data related to equipment and measuring point data that can reflect the overall working condition; filter the above data to ensure that the selected data is equipment Operating data under normal conditions, and delete overrun and invalid data;

[0067] (2) Transform and standardize the data obtained in step (1) to make the data meet the input and output dimension requirements of the multi-input multi-output ResNet network, and eliminate the difference in data dimension, and finally obtain the training data set.

[0068] Among them, the basis for transforming the data matrix is:

[0069] After step (1), the sample data should be an m×n order matrix:

[0070]

[0071] Am...

Embodiment 3

[0078] According to the multi-input multi-output ResNet network-based device intelligent early warning method described in Embodiment 1 or 2, the specific process of the step (2) is:

[0079] For the filtered m*n order data matrix M, where m is the number of samples, n is the number of measuring points, that is, the number of features, locate the position k that represents the features reflecting the overall working conditions, and then remove the k features for the matrix M Each feature of each feature is processed, and the number of cycles is n-1; the feature processing process of the i-th cycle is specifically:

[0080] order ,Save as ,in ;

[0081] yes The data is standardized to eliminate each feature dimension, and the standardized matrix is saved as , the standardized formula is:

[0082] Save the mean value and variance vector of each feature in the data structure middle;

[0083] After the loop ends, the following tuples are constructed:

[0084] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com