Super-large special-shaped curved surface enamel plate modeling unit type curtain wall system

A special-shaped curved surface and unitized technology, which is applied to the installation of walls, building structures, and window glass, can solve problems that cannot be dealt with, and achieve the effects of guaranteed quality, easy assembly, and easy control of installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

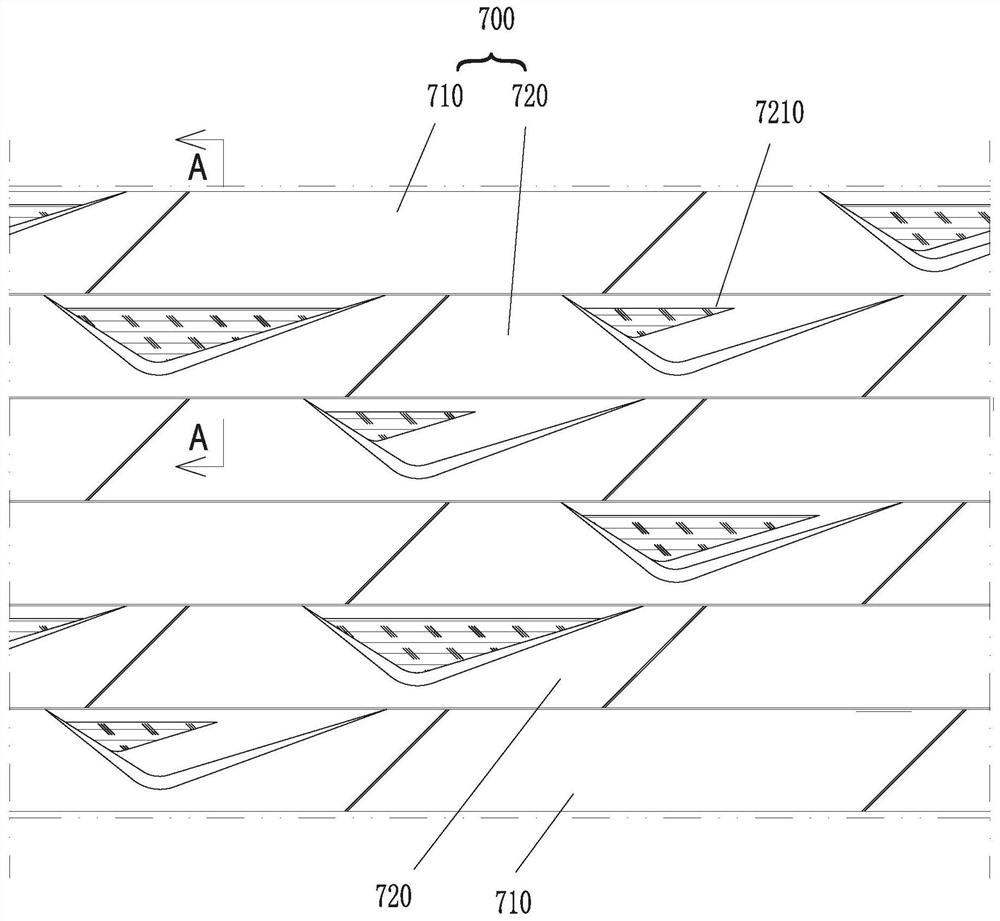

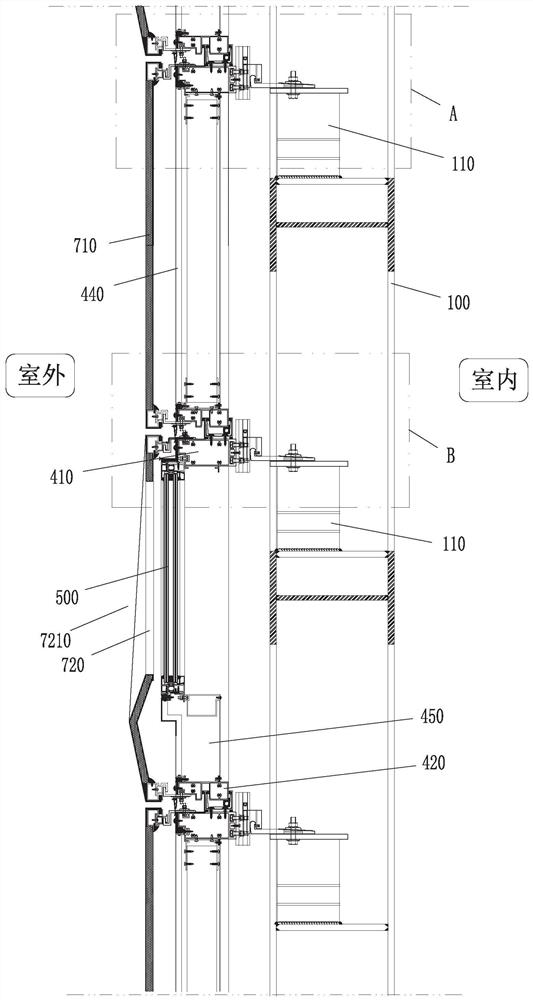

[0016] Such as Figure 1 to Figure 8 As shown, the ultra-large and special-shaped curved surface enamel plate modeling unit curtain wall system of the present invention includes a plurality of unit frames 400 hung on the main structure 100, and two unit frames adjacent to each other horizontally and vertically adjacent to each other 400 are plugged and connected to form a whole, and an enamel composite plate 700 is correspondingly mounted on the outside of each unit frame 400, that is, the unit frame 400 and the enamel composite plate 700 are overlapped and arranged, wherein: the unit frame 400 and the enamel composite plate 700 are both The shapes match each other and are parallelograms that are horizontally long and flat. The enamel composite plate 700 is super-large in size (usually up to 7.2m x 1.2m in length x height) and curved; each unit frame 400 is staggered, That is to say, the staggered joints are arranged between each enamel composite plate 700; the enamel composit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com