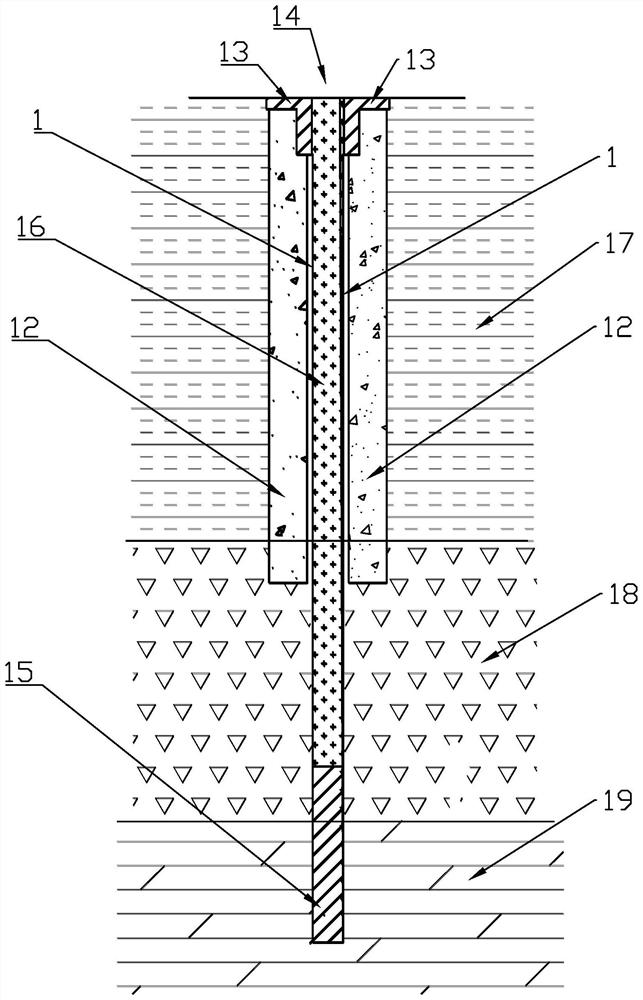

Construction method of flexible vertical anti-seepage wall for blocking underground water pollution

A technology of groundwater pollution and construction method, which is applied in the field of flexible vertical cut-off wall construction, and can solve the problems of HDPE geomembrane laying down, membrane connection and groove formation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] S101. After hydrological and geological conditions investigation and pollution investigation in the early stage of the site, the designer proposes the anti-seepage path and anti-seepage depth, and the construction party conducts site measurement and setting-out. When there are construction obstacles in the seepage path in space, timely communicate with the supervisor, construction party and designer for changes.

[0061] S102. Clean up and level the construction work surface, remove obstacles within 2 meters below the ground of the construction site, and clean up caves on the foundation soil or tree roots, garbage and other sundries on the surface of the foundation. According to the comparison between the original landform elevation and the design elevation, the construction volume for site leveling is calculated, and the sundries transportation route map and traffic guidance plan are drawn. At the same time, rationally arrange the positions of construction machinery, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width on one side | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com