Self-cleaning type glass product processing device

A technology for glass products and processing devices, which is applied to manufacturing tools, stone processing tools, stone processing equipment, etc., can solve the problems of reduced water flow, difficulty in realizing self-circulation of water flow, and long time required for filtration, and achieves high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

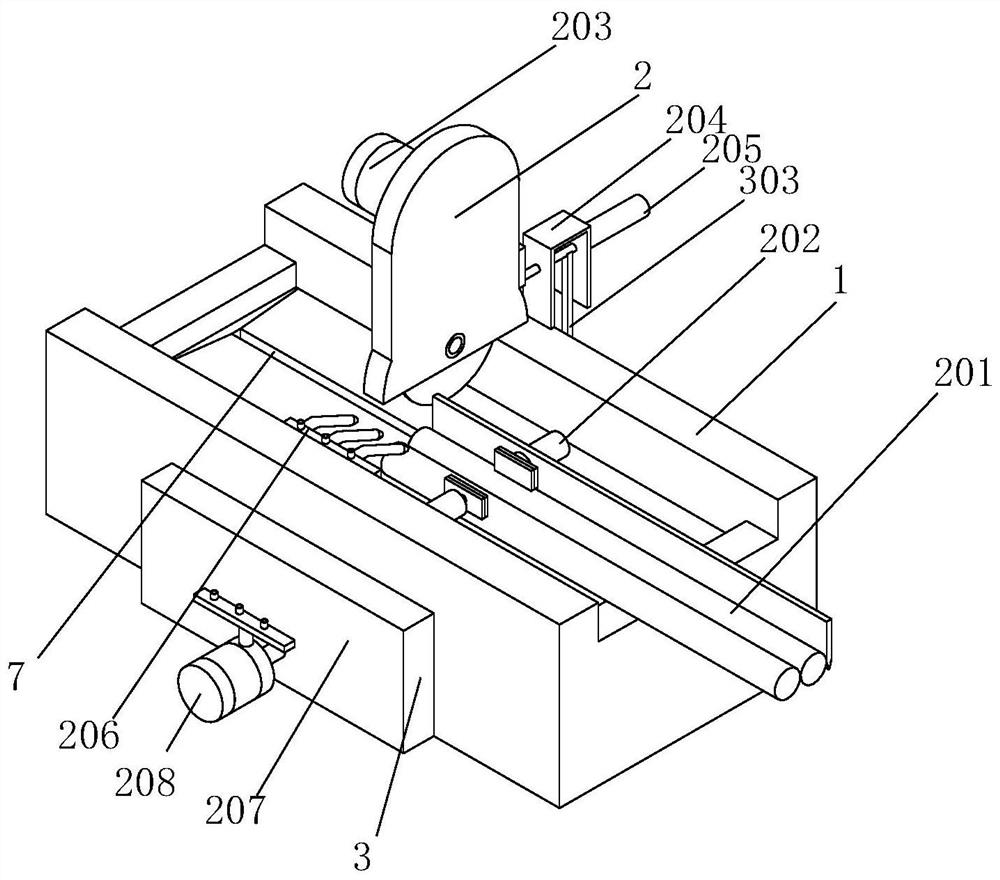

[0037] Example 1: Please refer to Figure 1-3 , a self-cleaning type glass product processing device, comprising a processing table 1, the top surface of the processing table 1 and the left and right sides are hollowed out, the inside of the processing table 1 is in a hollowed out state, the top surface of the processing table 1 is provided with a processing mechanism 2, and the processing A cleaning mechanism 3 is arranged inside the table 1, and the processing mechanism 2 includes a transmission table 201, a clamping mechanism 202 and a cutting mechanism 203. The transmission table 201 is fixedly installed on the right side of the top surface of the processing table 1, and the number of the clamping mechanisms 202 is two and They are respectively arranged on the processing table 1 and the transmission table 201 in an opposing state. The back side of the processing table 1 is fixedly connected with a fixed frame 204. The back side of the fixed frame 204 is fixedly equipped wit...

Embodiment 2

[0038] Embodiment 2: On the basis of Embodiment 1, please refer to Figure 4-7 The anti-blocking mechanism 4 includes a pneumatic cylinder 401, the front side of the connecting rod 304 is hollowed out, the middle part of the connecting rod 304 is in a cut state and is fixedly connected and communicated with the pneumatic cylinder 401, the inner wall of the pneumatic cylinder 401 is sleeved with a piston A402, and the front of the piston A402 The side is fixedly connected with a pull rod 404, the front end of the pull rod 404 is fixedly connected with the guide plate 305, the connecting rod 304 is fixedly connected with a magnetic ring 403 on the inner wall behind the piston A402, and the piston A402 is attracted by the magnetic force of the magnetic ring 403. When cutting larger glass products, the transmission shaft of the telescopic cylinder 205 needs to be extended slowly during the cutting process, so that the guide plate 305 will not approach the water flow immediately wit...

Embodiment 3

[0040] Embodiment three: on the basis of embodiment two, please refer to Figure 8-9 The water level detection mechanism 5 includes a water suction pipe 501 and a cylinder 502. The bottom surface of the connecting rod 304 is fixedly connected and communicated with the cylinder 502 at the position between the two air guide cylinders 405. The inner wall of the back of the processing table 1 is arranged and communicated with five vertically distributed The suction pipe 501 and the bottom end of the cylinder 502 are fixed and communicated with a suction pipe 501 through the liquid pipe 504. The inner wall of the cylinder 502 is fitted with a piston B503. Springs and baffles require high pressure for extraction and exhaust, so the air will be extracted and injected into the cylinder 502 first, and the extraction and injection of air in the cylinder 502 will drive the reciprocating sliding of the piston B503, and the piston B503 will slide upwards At the same time, the air or water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com