A kind of multi-strand billet casting machine anti-accident expansion control method and system

A control method and a technology for sudden accidents, which are applied in the field of equipment and personal safety, multi-strand billet continuous casting production to prevent sudden accidents, and can solve the problem that the blind plate blocking operation cannot be performed and the recovery time of the casting machine is long. , personnel injury equipment and other issues, to achieve the effect of improving the emergency handling capacity of accidents, standardizing the emergency handling procedures, and protecting the safety of people and equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

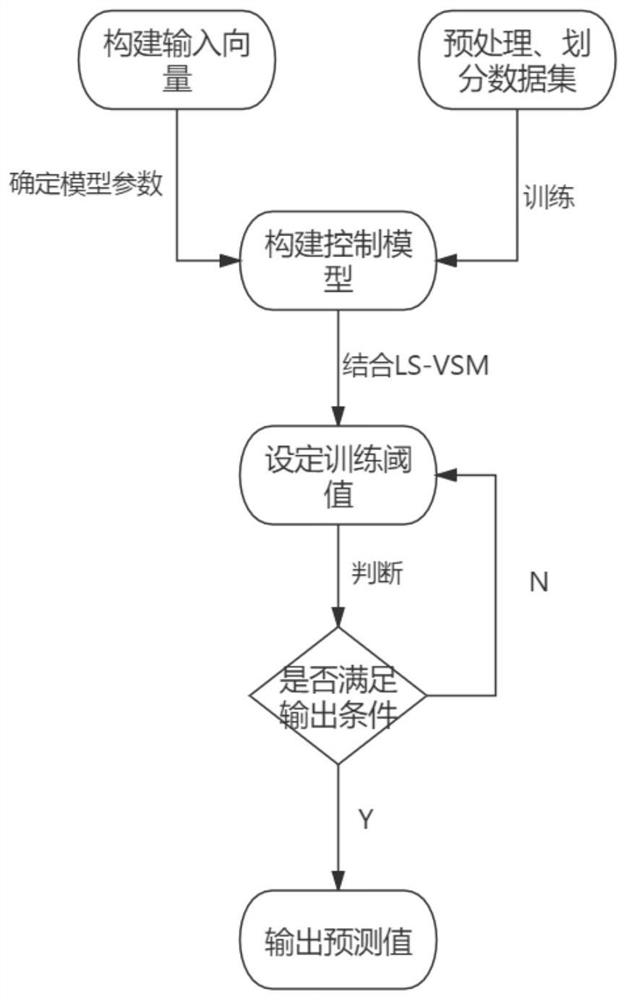

[0040] refer to figure 1 and figure 2 , which is the first embodiment of the present invention, provides a multi-stream billet casting machine anti-accident expansion control method, characterized in that: comprising:

[0041] S1: Build the input vector based on the least squares support vector machine. It should be noted that:

[0042] The time series strategy is a set of one-dimensional observations. When combined with the least squares support vector machine, phase space reconstruction is required. The construction of the input vector includes,

[0043] X(k)=[x(k), x(k-τ), ..., x(k-(D-1)τ)]

[0044] where D is the embedding dimension of the phase space reconstruction, τ is the delay time of the phase space reconstruction, and X(k) is the input-output vector pair.

[0045] S2: Preprocess the collected sample data, divide the data set, and confirm the model parameters for the input vector. What needs to be explained in this step is:

[0046] Preprocessing includes miss...

Embodiment 2

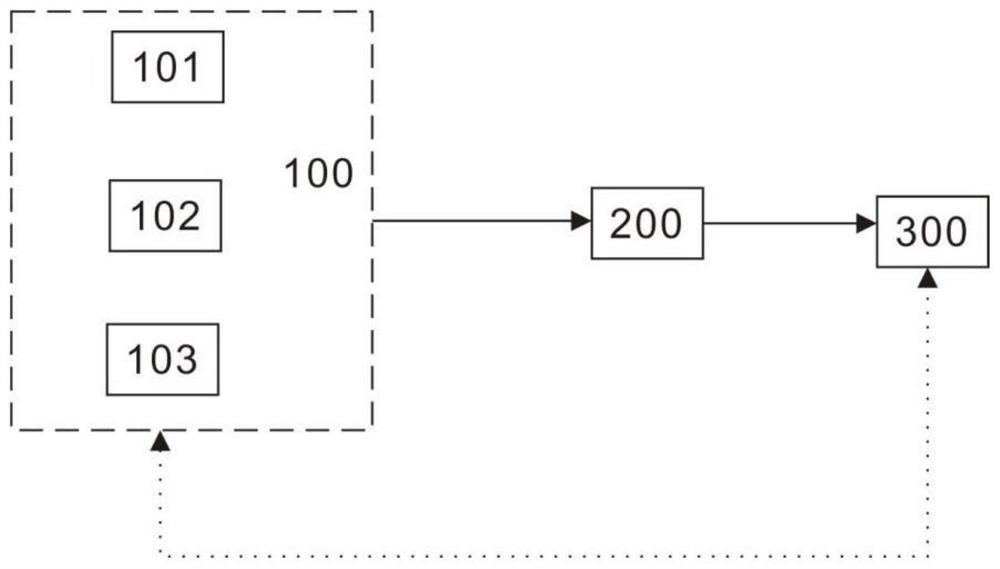

[0066] refer to Figure 3 to Figure 7 , is the second embodiment of the present invention, which is different from the first embodiment in that it provides a multi-strand billet casting machine anti-accident expansion control system, including:

[0067] refer to Figure 4 , Figure 5 and Figure 7 , the hydraulic module 100 is used to meet the one-button independent operation in the event of an accident. It includes a hydraulic station lead-out oil pipe 101, a hydraulic cylinder 102 and a blind plate 103. The hydraulic station lead-out oil pipe 101 moves with the tundish to provide power for the hydraulic cylinder 102 , each casting strand is independently equipped with hydraulic cylinder equipment and can be operated independently, and the hydraulic cylinder 102 is used with the blind plate 103; the hydraulic module 100 is also provided with a one-button button, which can control the hydraulic cylinder equipment of each stream at the same time. One-click button, each casti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com