CAD and BIM-based batch deepening design method for fabricated structure laminated slabs

A technology for detailed design and laminated slabs, applied in geometric CAD, design optimization/simulation, floor slabs, etc., can solve problems such as low design quality, lack of construction data, and poor parametric control performance, so as to improve the quality of detailed design and facilitate Accurate effect of promotion and design results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

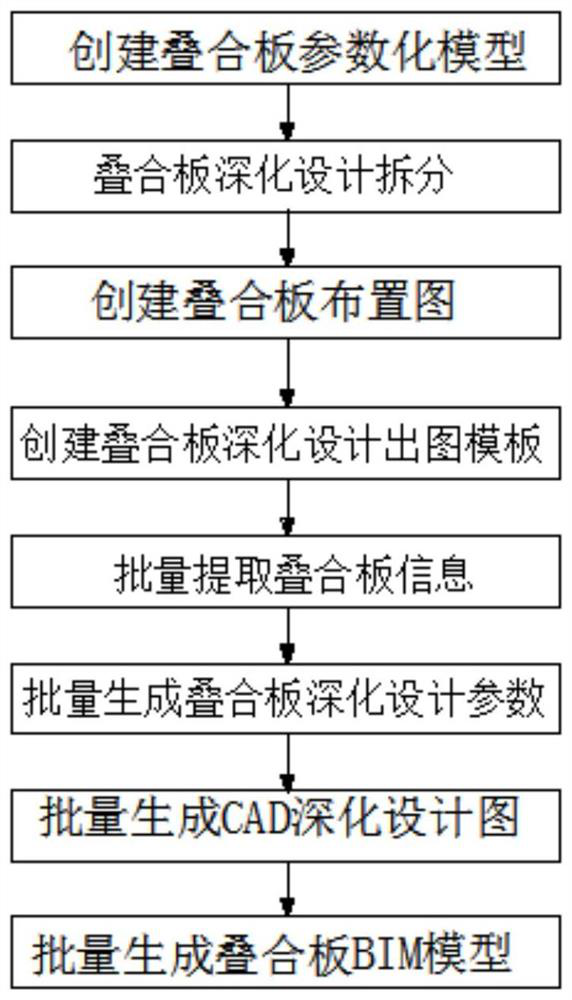

[0060] A method for batch deepening design of prefabricated structural laminated panels based on CAD and BIM, characterized in that:

[0061] The method steps are as follows:

[0062] 1. Create a parametric digital model and drawing template for the detailed design of laminated panels suitable for CAD and BIM platforms;

[0063] 2. In the CAD platform-based floor slab construction drawing, split the floor into laminated slabs, draw the laminated slab outline, create and fill in the laminated slab information form within the outline, and generate the laminated slab floor plan;

[0064] 3. Through the secondary development of CAD, write a program to extract the outline information of the laminated board in the plan layout of the laminated board and the information in the laminated board information table in batches;

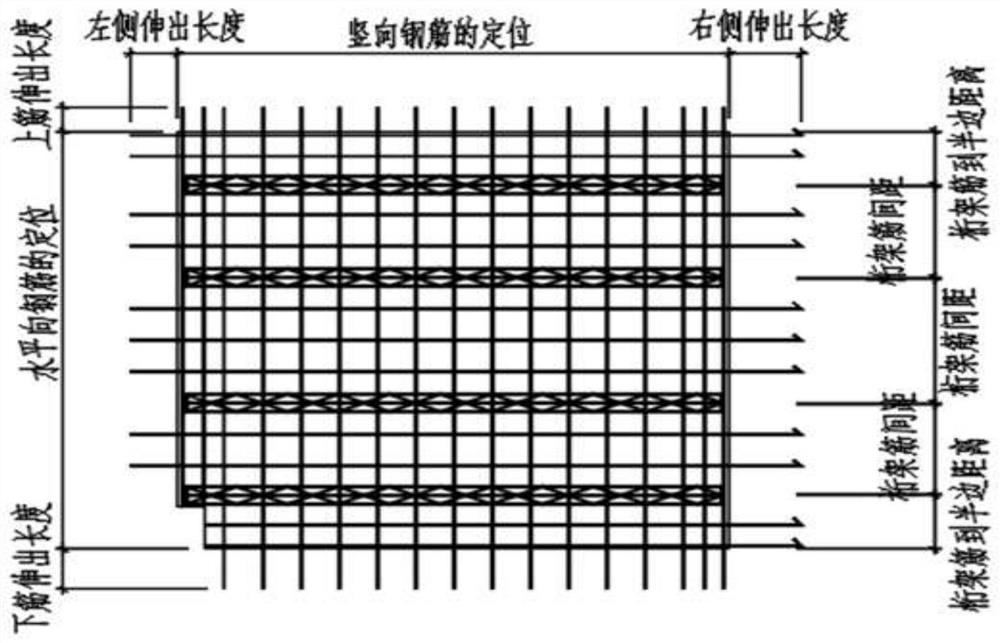

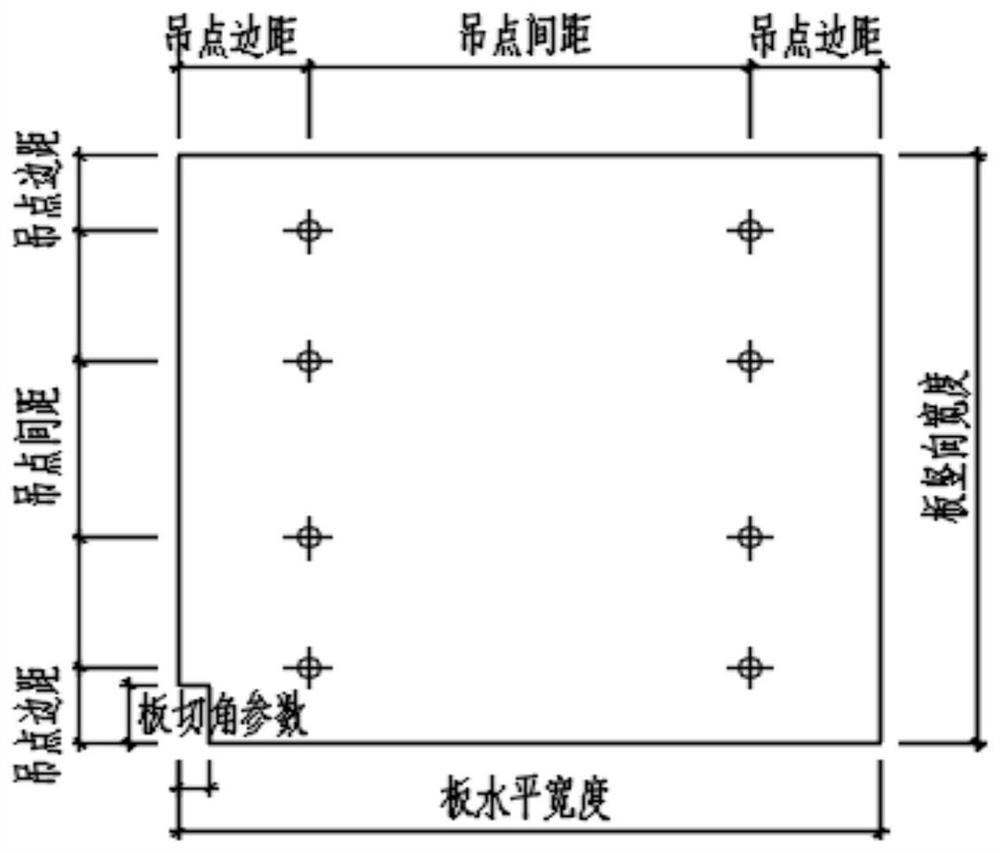

[0065] 4. The program calculates the number and corresponding spacing of the truss bars of the laminated slab based on the information extracted in the "3" step, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com