Fan blade supporting structure, air conditioner outdoor unit and air conditioner

A technology of supporting structure and fan blades, which is used in air-conditioning systems, space heating and ventilation, and home heating, etc., can solve the problems of increased motor shaft friction, decreased motor efficiency, and offset of the center of gravity of fan blades to reduce jitter. , improve efficiency, optimize the effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

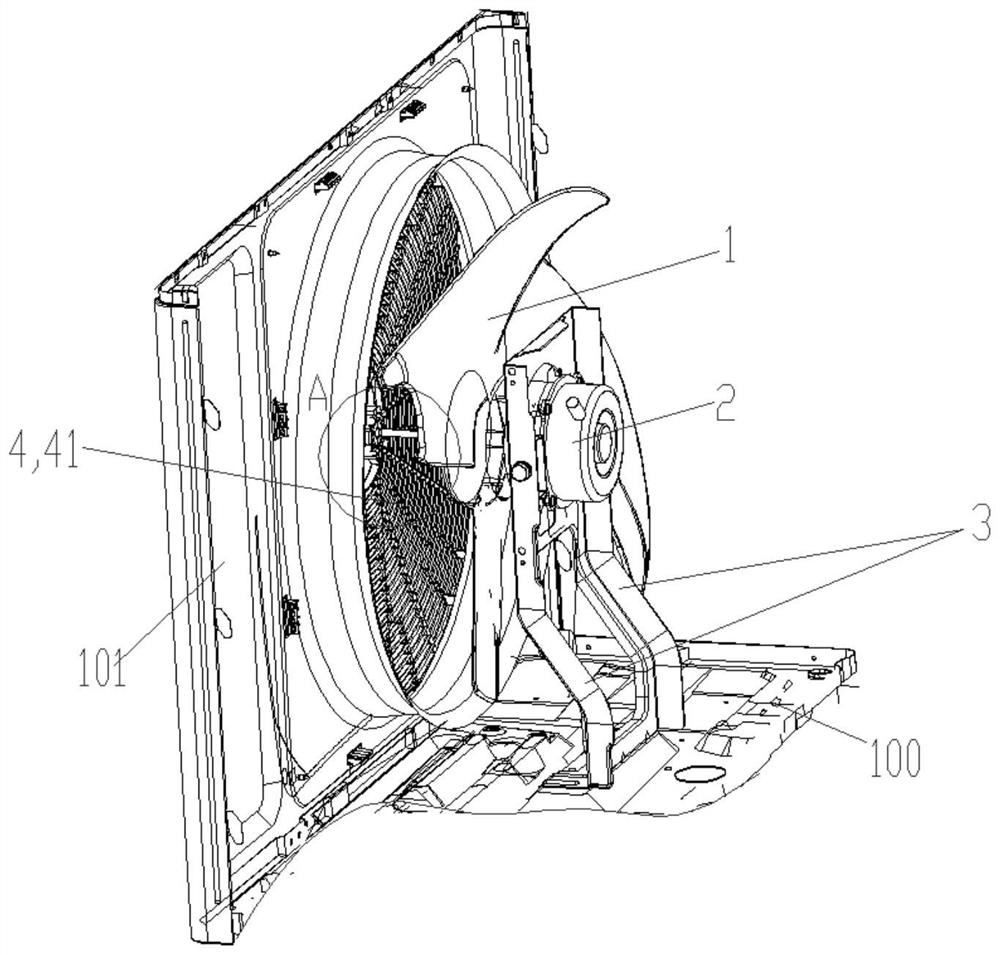

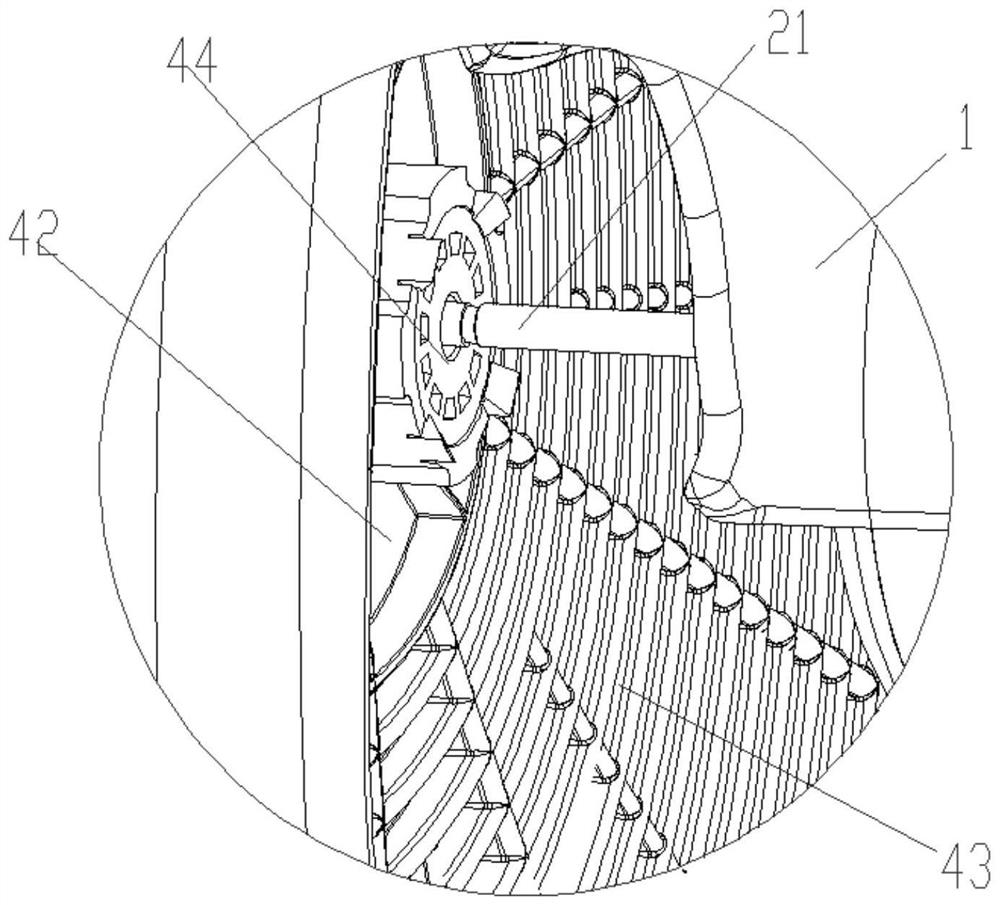

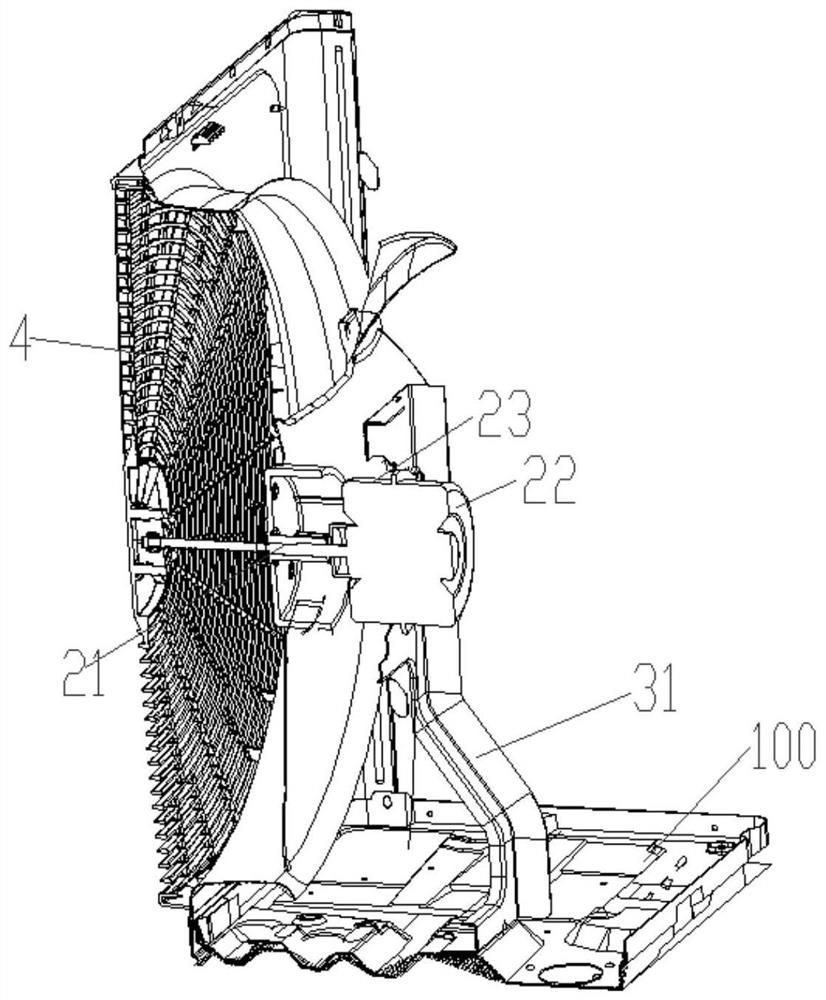

[0037] see in conjunction Figure 1 to Figure 12 As shown, according to the embodiment of the present invention, a fan blade support structure is provided, including the fan blade 1, and the fan blade 1 is sleeved on the power output shaft 21 of the driving motor 2. It can be understood that the fan blade 1 passes through The fan blade lock nut 102 is locked at the preset position of the power output shaft 21, and also includes a motor bracket 3 and a shaft end support 4, and the driving motor 2 is connected (preferably detachably connected) to the motor bracket 3, the shaft end support 4 is connected to the free end of the power output shaft 21 (that is, the end of the power output shaft 21 protruding from the drive motor 2). In this technical solution, one end of the power output shaft 21 is supported by the motor bracket 3, and the other end (that is, the free end) of the power output shaft 21 is supported by the shaft end support 4, thereby The power output shaft of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com