Flexible shaft used for nuclear power plant finger casing core signal transmission and preparation method thereof

A signal transmission and finger sleeve technology, applied in the direction of flexible shafts, centrifugal force-resistant rotating parts, shafts, etc., can solve the problems of pipe wall damage, difficulty in adapting, and inability to install copper cores, etc., to meet long-distance push-pull and ensure stability Good running and flexible shaft stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

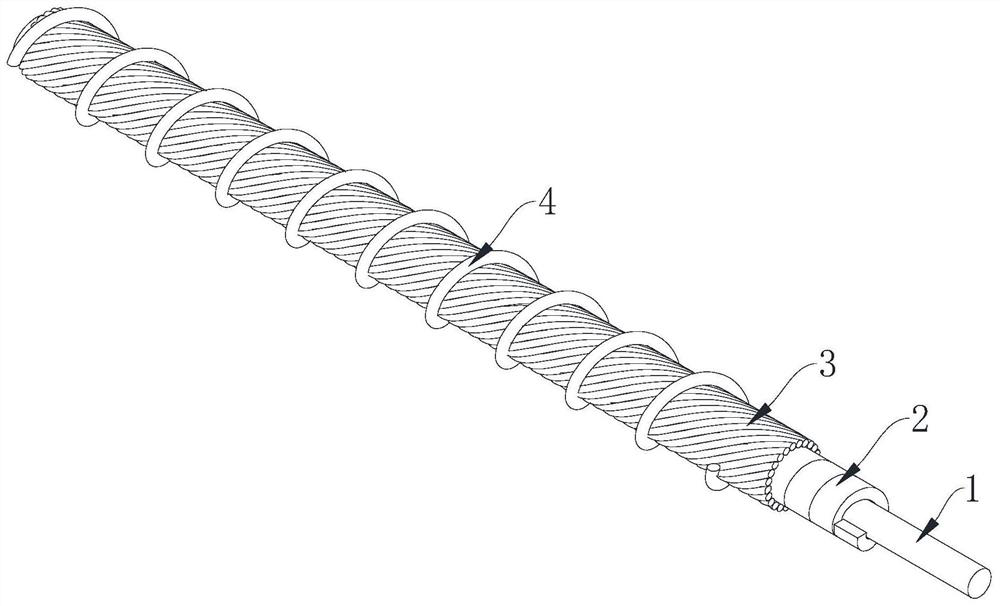

[0040] The present invention also provides a preparation method for preparing the above flexible shaft, comprising the following steps:

[0041] S0: pressing the third metal wire with a preset diameter into a metal strip with a preset width and thickness at a preset pressure.

[0042] Wherein, the third metal wire can be a steel wire with a steel quality of 45-65 steel and a preset diameter of φ0.5-1.6mm, and the preset pressure can be 80±10kN. The width and thickness can be set to be 0.8-2 mm and 0.3-0.6 mm, respectively.

[0043] Understandably, in other embodiments, the cross section of the third metal wire may also be in other shapes such as square. In some other embodiments, the metal strip with preset width and thickness can also be provided directly, so that step S0 can also be omitted.

[0044] S1: performing a first heat treatment on a metal strip with a preset width and thickness, so that the hardness of the metal strip is increased from a first preset hardness to ...

Embodiment

[0065] With a preset pressure of 80kN, the third metal wire made of manganese steel-65Mn and with a preset diameter of φ0.8mm is pressed into a steel strip with a width of 1.2mm, a thickness of 0.4mm, and a hardness of 19 degrees;

[0066] The steel strip is preheated to about 100°C by an electric furnace, and the quenching is quickly completed within 0.5s. After the quenching is completed, the hardness of the steel strip is increased to about 45 degrees;

[0067] A single single layer of quenched steel strips is spirally wound side by side with a first pitch of 0.4mm to form a supporting protective layer 2 with a preset outer diameter and inner diameter of 2.5mm and 1.7mm respectively;

[0068] Use 1.5mm peripheral felt steel wire to polish the inner wall surface of the supporting protective layer 2;

[0069] 20 first metal wires made of manganese steel-65Mn with a diameter of about φ0.4mm are tightly wound on the outer surface of the supporting protective layer 2 with a pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com