Alkaline solution hydrogen evolution electrocatalyst NiVRu ternary alloy as well as preparation method and application thereof

An alkaline solution and electrocatalyst technology, applied in electrodes, electrolysis processes, electrolysis components, etc., to achieve good hydrogen evolution catalytic performance in alkaline electrolyzed water, simple preparation method, and excellent alkaline hydrogen evolution performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

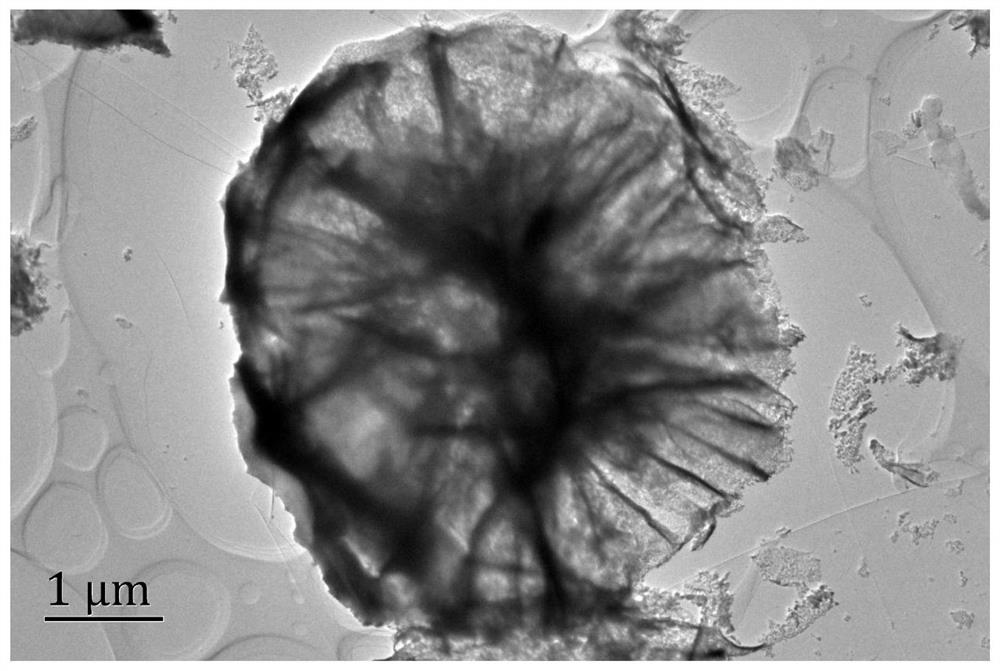

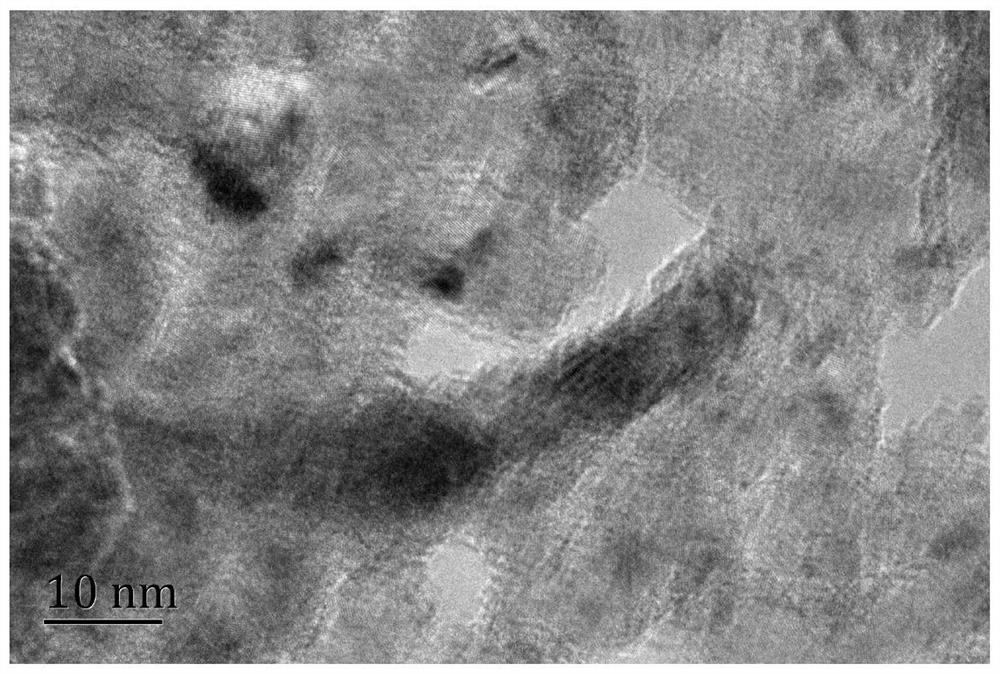

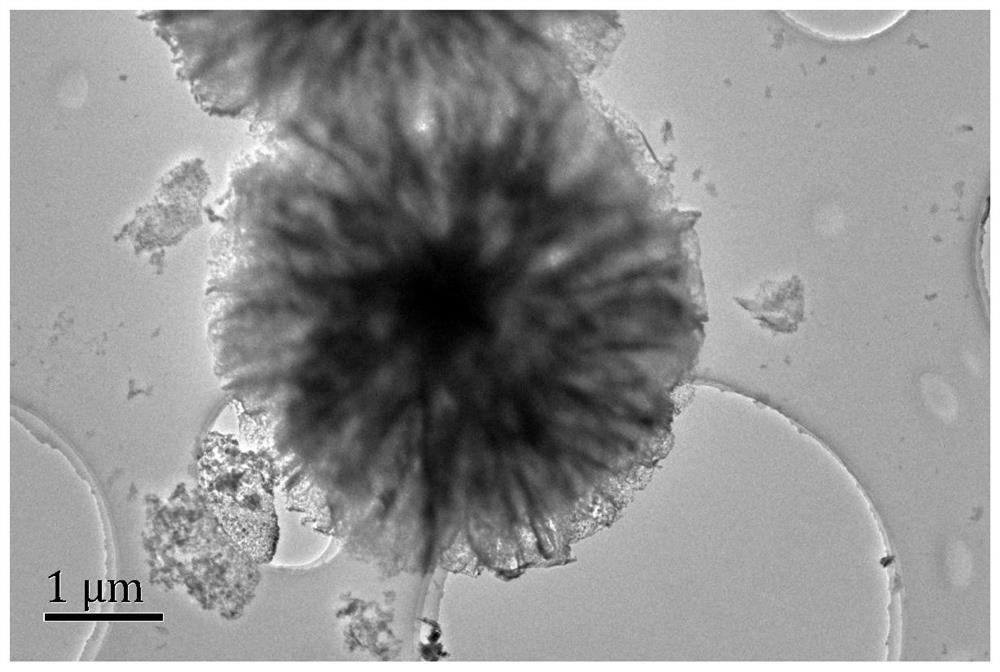

Image

Examples

Embodiment 1

[0038] (1) Weigh 2.7mmol nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O), 0.3mmol vanadium chloride (VCl 3 ) was dissolved in 60mL of purified water, and then 15mmol of urea (CH 4 N 2 O), stirred for 15 minutes to obtain a green mixed solution.

[0039] (2) Pour the above green mixed solution into a polytetrafluoroethylene hydrothermal reaction kettle, put the hydrothermal reaction kettle into a blast drying oven, react for 4 hours under hydrothermal conditions at 120°C, and turn off the blast drying Cool the reactor to room temperature;

[0040] (3) Centrifuge the product obtained in the reaction kettle, wash twice with pure water solvent, then wash twice with ethanol solvent, and put it into a vacuum drying oven to dry to obtain a light yellow powder;

[0041] (4) Weigh 20 mg of the yellow powder obtained in step (3) and dissolve it in 25 mL of pure aqueous solution, add 0.5 mg of RuCl 3 Stir to obtain a mixed solution;

[0042] (5) Pour the mixed solution obtained in...

Embodiment 2

[0051] (1) Weigh 8mmol nickel chloride (NiCl 2 ), 0.4mmol of vanadium chloride was dissolved in 60mL of purified water, then 18mmol of urea was added, and stirred for 15 minutes to obtain a green mixed solution.

[0052] (2) Pour the above green mixed solution into a polytetrafluoroethylene hydrothermal reaction kettle, put the hydrothermal reaction kettle into a blast drying oven, react for 2 hours under hydrothermal conditions at 150°C, and turn off the blast drying Cool the reactor to room temperature;

[0053] (3) Centrifuge the product obtained in the reaction kettle, wash twice with pure water solvent, then wash twice with ethanol solvent, and put it into a vacuum drying oven to dry to obtain a light yellow powder;

[0054] (4) Weigh 10 mg of the yellow powder obtained in step (3) and dissolve it in 50 mL of pure aqueous solution, add 1.0 mg of RuCl 3 Stir to obtain a mixed solution;

[0055] (5) Pour the mixed solution obtained in step (4) into a hydrothermal reactio...

Embodiment 3

[0060] (1) Weigh 12mmol of nickel sulfate and 3mmol of vanadium chloride in 80mL of pure water, then add 150mmol of urea and stir for 15 minutes to obtain a green mixed solution.

[0061] (2) Pour the above green mixed solution into a polytetrafluoroethylene hydrothermal reaction kettle, put the hydrothermal reaction kettle into a blast drying oven, react under hydrothermal conditions at 90°C for 10 hours, and turn off the blast drying Cool the reactor to room temperature;

[0062] (3) Centrifuge the product obtained in the reaction kettle, wash twice with pure water solvent, then wash twice with ethanol solvent, and put it into a vacuum drying oven to dry to obtain a light yellow powder;

[0063] (4) Weigh 20 mg of the yellow powder obtained in step (3) and dissolve it in 25 mL of pure aqueous solution, add 2.0 mg of RuCl 3 Stir to obtain a mixed solution;

[0064] (5) Pour the mixed solution obtained in step (4) into a hydrothermal reaction kettle, react under hydrothermal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com