Fish oil continuous refining method and centrifugal equipment used in fish oil continuous refining method

A centrifugal equipment and fish oil technology, applied in centrifuges, fat oil/fat refining, fat production, etc., can solve the problems of inconvenient real-time monitoring of material volume, insufficient removal of soapstock, insufficient addition of lye, etc., to achieve observation and display use Convenient and fast, reasonable and effective display structure, efficient and stable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

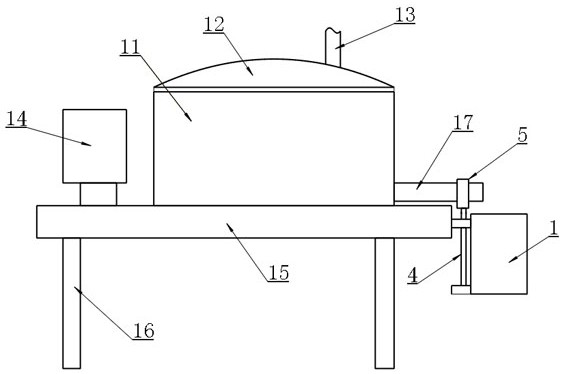

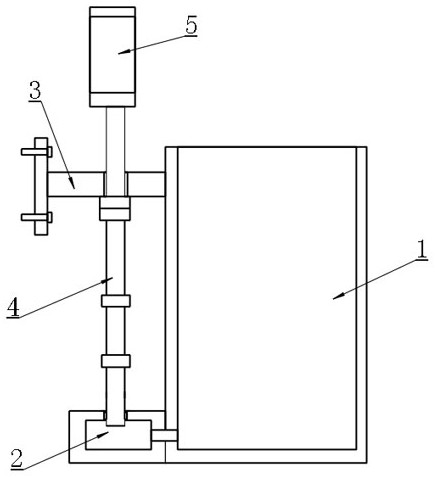

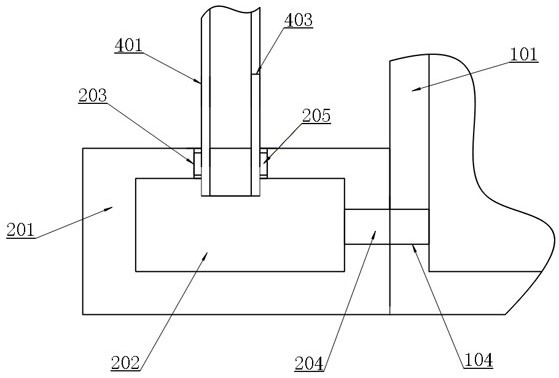

[0028] Example: as attached figure 1 , 2 , 3, 4, 5 and attached Figure 6 As shown, a continuous refining method for fish oil includes four steps of cleaning and filtering, alkali refining and desoaping, filtering and decolorization, and winterization and filtering. 80-95°C, then add to the centrifuge, then add lye with a concentration of 15-25 degrees Baume while centrifuging, and finally complete the centrifugal soap removal to reduce the acid value of fish oil.

[0029] In this embodiment, the heating temperature of 80-95°C can ensure that the lye reacts better with the free fatty acid, and converts as much free fatty acid as possible into centrifuge-separatable soapstock, wherein the lye is divided into batches Add, and monitor the centrifugal output of soapstock in real time, such as setting the centrifugal output speed of soapstock to be less than 20g / min, just stop adding lye, like this just can guarantee that free fatty acid as much as possible is removed, and alkali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com