Line porcelain insulator blank and process for producing porcelain insulator by using blank

A technology for porcelain insulators and insulators, applied in the field of line porcelain insulator production, can solve the problems of unreasonable ratio of clay raw materials and barren raw materials, damage to line use and operating life, unstable porcelain performance, etc., and the production process is easy to control. , The effect of good production process performance and wide firing temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A line porcelain insulator blank, characterized in that the blank is composed of clay raw materials and barren raw materials in a mass ratio of 2:1;

[0054] The clay raw material is composed of the following components in weight percent:

[0055] Silicon dioxide 41%, aluminum oxide 40%, ferric oxide 1.5%, calcium oxide ≤ 1.0%, magnesium oxide ≤ 1.0%, the total of sodium oxide and potassium oxide ≤ 3.0, titanium dioxide ≤ 1.5, the balance is other impurities ;

[0056] Described barren raw material is made up of the component of following percentage by weight:

[0057] Porcelain powder 40%

[0058] Bauxite powder 60%

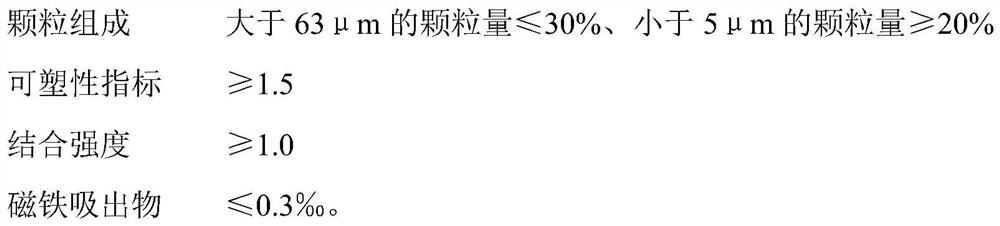

[0059] The quality standard of described clay raw material is as follows:

[0060]

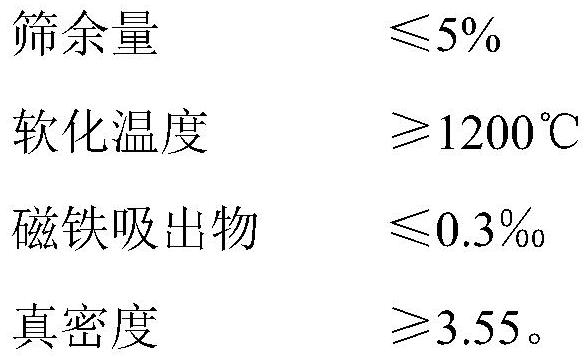

[0061] The quality standard of described spine raw material is as follows:

[0062]

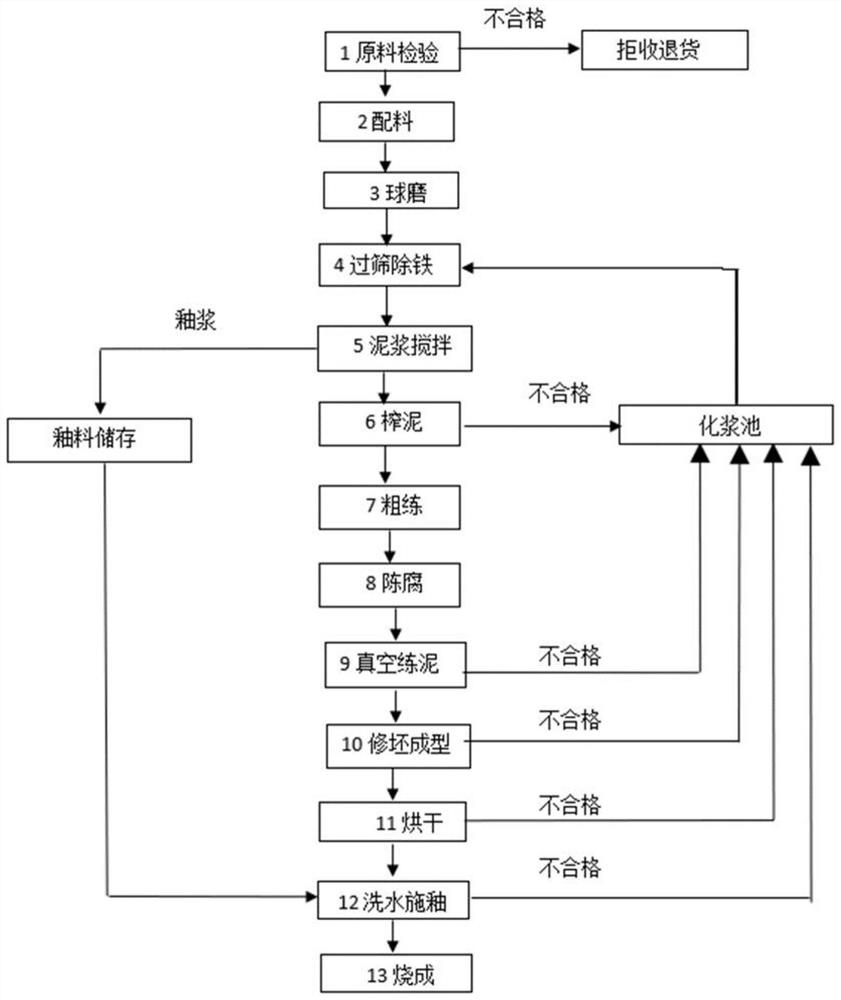

[0063] The process of producing porcelain insulators according to the above-mentioned circuit porcelain insulator blank formula, the steps are as follows:

[0064] (1) Raw ma...

Embodiment 2

[0087] The embryo material is composed of clay raw material and barren raw material in a mass ratio of 3:1;

[0088] The clay raw material is composed of the following components in weight percent:

[0089] Silicon dioxide 61%, aluminum oxide 33%, ferric oxide 1.7%, calcium oxide ≤ 1.0%, magnesium oxide ≤ 1.0%, the total of sodium oxide and potassium oxide ≤ 3.0, titanium dioxide ≤ 1.5, and the balance is impurities;

[0090] Described barren raw material is made up of the component of following percentage by weight:

[0091] Porcelain powder 50%

[0092] Bauxite powder 50%.

[0093] The quality standard of described clay raw material is as follows:

[0094]

[0095] The quality standard of described spine raw material is as follows:

[0096]

[0097]

[0098] The process of producing porcelain insulators according to the above-mentioned circuit porcelain insulator blank formula, the steps are as follows:

[0099] (1) Raw material inspection: inspect the clay raw...

Embodiment 3

[0122] A line porcelain insulator blank, characterized in that the blank is composed of clay raw material and barren raw material in a mass ratio of 5:1;

[0123] The clay raw material is composed of the following components in weight percent:

[0124] Silicon dioxide 77%, aluminum oxide 16%, ferric oxide 1.5-2%, calcium oxide ≤ 1.0%, magnesium oxide ≤ 1.0%, the total of sodium oxide and potassium oxide ≤ 3.0, titanium dioxide ≤ 1.5, the balance is other impurities;

[0125] Described barren raw material is made up of the component of following percentage by weight:

[0126] Porcelain powder 60%

[0127] Bauxite powder 40%.

[0128] The quality standard of described clay raw material is as follows:

[0129]

[0130] The quality standard of described spine raw material is as follows:

[0131]

[0132] The process of producing porcelain insulators according to the above-mentioned circuit porcelain insulator blank formula, the steps are as follows:

[0133] (1) Raw ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com