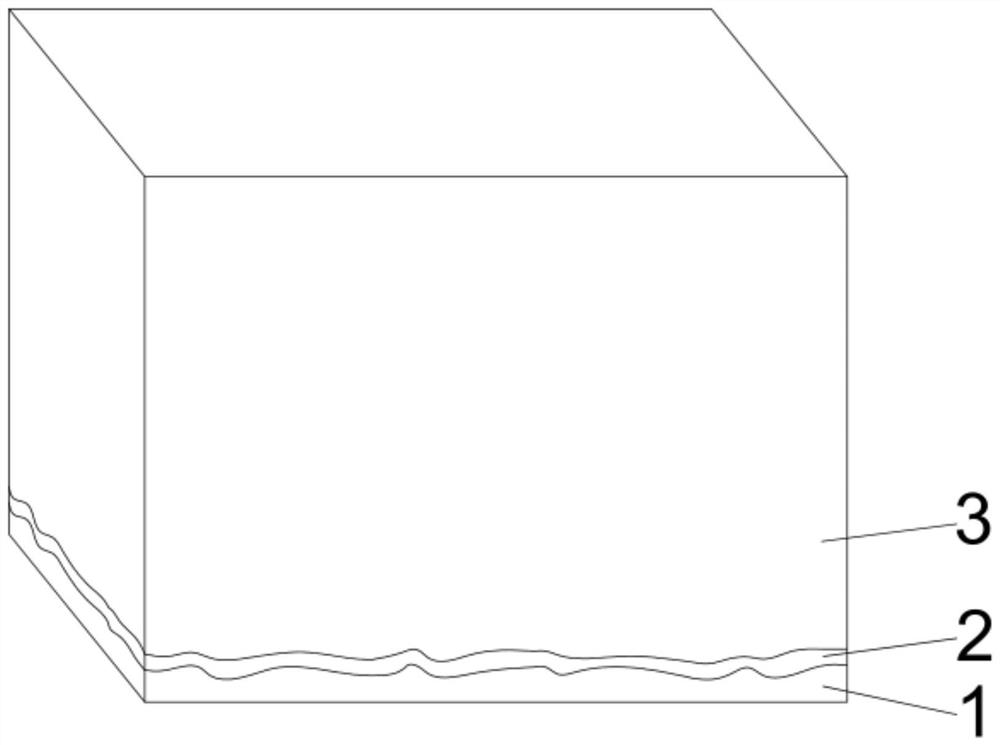

Autoclaved aerated concrete and preparation method thereof

An autoclaved aerated concrete technology, which is applied in chemical instruments and methods, ceramic products, other household appliances, etc. Layer detachment and other problems, to achieve the effect of improving the phenomenon of poor hardening and cracking, reducing temperature, and avoiding water swelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of autoclaved air-entrained concrete preparation method described in this embodiment comprises the following steps:

[0035] a. Portland cement, granite with a particle size of 2mm, fly ash, silicon powder, naphthalene-based superplasticizer, cellulose ether, redispersible polymer latex powder and anti-cracking agent in a mass ratio of 55:15 : 20: 8: 1: 5: 4: 8 Mix evenly and add water to make the outer layer concrete;

[0036] Mix Portland cement, 60 mesh quartz sand, 200 mesh heavy calcium powder, redispersible polymer latex powder, cellulose ether and anti-cracking agent according to the mass ratio of 55:30:8:4:4:6 and add water evenly Make connecting layer concrete;

[0037] Mix 425 ordinary Portland cement, fly ash, lime, gypsum, aluminum powder paste and waste slurry according to the mass ratio of 17:67:23:3:0.05:3 and add water to make the core concrete.

[0038] b. Fill the mold horizontally and evenly with 10mm thick outer layer concrete;

[0039] c. ...

Embodiment 2

[0043] A kind of autoclaved air-entrained concrete preparation method described in this embodiment comprises the following steps:

[0044] a. Portland cement, granite with a particle size of 3mm, fly ash, silicon powder, naphthalene-based superplasticizer, cellulose ether, redispersible polymer latex powder and anti-cracking agent in a mass ratio of 60:15 : 25: 9: 1: 5: 4: 8 Mix evenly and add water to make the outer layer concrete;

[0045] Mix Portland cement, 60 mesh quartz sand, 200 mesh heavy calcium powder, redispersible polymer latex powder, cellulose ether and anti-cracking agent according to the mass ratio of 60:30:8:5:4:8 and add water evenly Make connecting layer concrete;

[0046] Mix 425 ordinary Portland cement, fly ash, lime, gypsum, aluminum powder paste and waste slurry according to the mass ratio of 18:68:23:2.5:0.06:3 and add water to make the core concrete.

[0047] b. Fill the mold horizontally and evenly with 10mm thick outer layer concrete;

[0048] c...

Embodiment 3

[0052] A kind of autoclaved air-entrained concrete preparation method described in this embodiment comprises the following steps:

[0053]a. Portland cement, granite with a particle size of 3mm, fly ash, silicon powder, naphthalene-based superplasticizer, cellulose ether, redispersible polymer latex powder and anti-cracking agent in a mass ratio of 65:20 : 25: 8: 1: 5: 4: 8 Mix evenly and add water to make the outer layer concrete;

[0054] Mix Portland cement, 60 mesh quartz sand, 200 mesh heavy calcium powder, redispersible polymer latex powder, cellulose ether and anti-cracking agent according to the mass ratio of 65:25:7:3:4:7 and add water evenly Make connecting layer concrete;

[0055] Mix 425 ordinary Portland cement, fly ash, lime, gypsum, aluminum powder paste and waste slurry according to the mass ratio of 18:67:23:2:0.06:3 and add water to make the core concrete.

[0056] b. Fill the mold horizontally and evenly with 10mm thick outer layer concrete;

[0057] c. H...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com