Trackless deformation portal lifting device

A gantry hoisting and hoisting device technology, applied in cranes, hoisting devices, circuit devices, etc., can solve the problems affecting the stability and smoothness of the track structure, separation, breakage or breakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

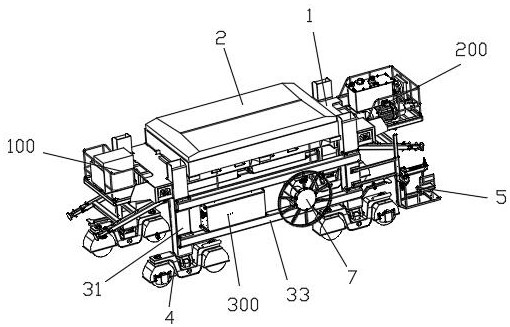

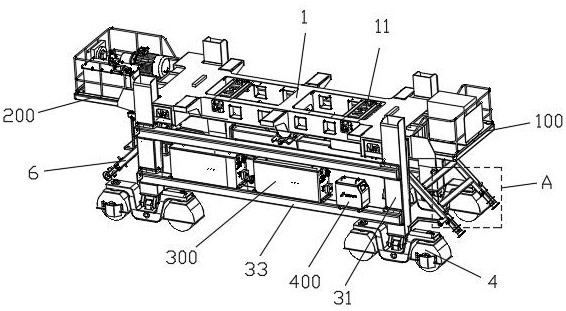

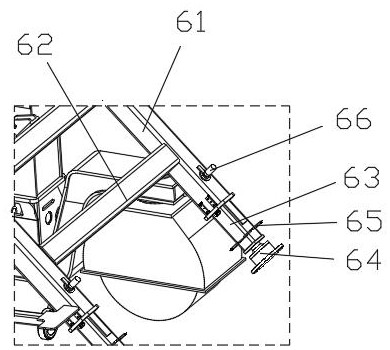

[0024] Such as Figure 1-5 As shown, a kind of trackless deformed gantry lifting device provided by the present invention comprises a frame 1, and both sides of each end of the frame 1 are provided with sliding holes, and telescopic beams are slidably connected in each sliding hole, and each A horizontal hydraulic cylinder for controlling the sliding of the telescopic beam in the sliding hole is housed in the sliding hole. The end of each telescopic beam away from the sliding hole is fixedly connected to the riser 31, and each riser 3 is equipped with a vertical cylinder for controlling the movement of the vertical column 32. The lifting hydraulic cylinder that slides in the pipe 3, the lower end of each column 32 is fixedly connected to the travel wheel set 4, the travel wheel set 4 includes a bracket 41, the upper middle part of the bracket 41 is hinged with the column 32, and is hinged between the bracket 41 and the column 32 Angle adjustment hydraulic cylinder 44 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com