Meat food processing workbench capable of preventing sweeps from splashing outwards

A meat food and workbench technology, which is applied in the field of food processing, can solve the problems of increased labor intensity, inconvenient cleaning, splashing of waste debris, etc., and achieve the effects of easy cleaning of the platen, saving labor intensity and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

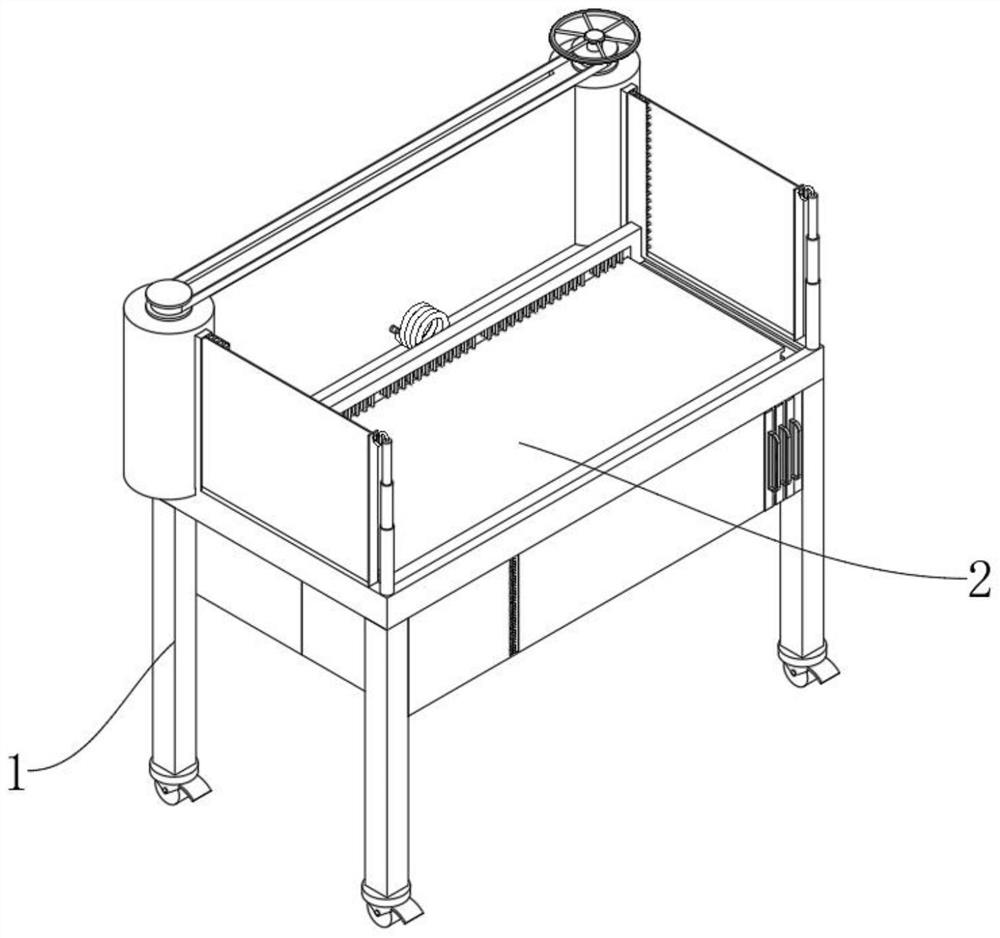

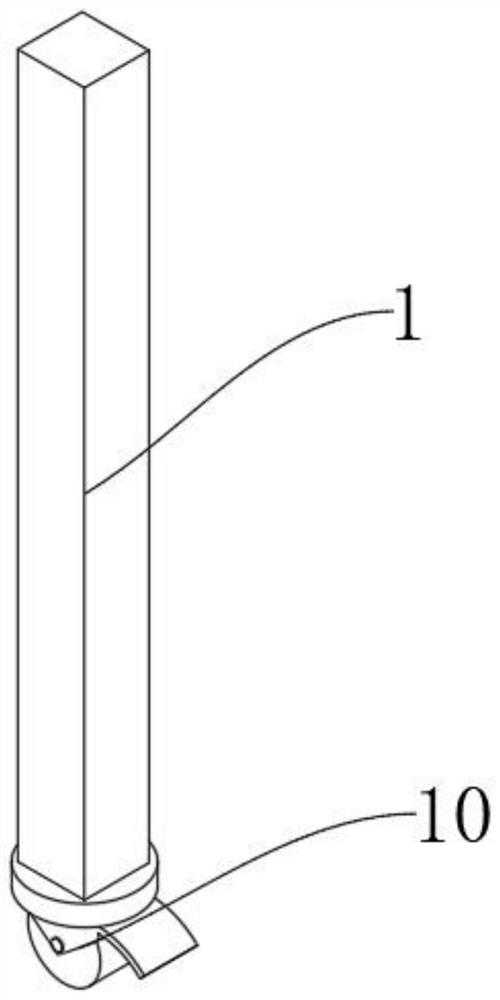

[0054] see Figure 1-Figure 12 As shown, this embodiment provides a workbench for meat food processing that prevents waste from splashing, including a support leg 1 and a workbench 2 on the top of the support leg 1, four support legs 1, and four support legs 1 ends are respectively fixedly arranged at the bottom of the workbench 2 near the corners, and the stability of the bottom of the workbench 2 is maintained by the four support legs 1 .

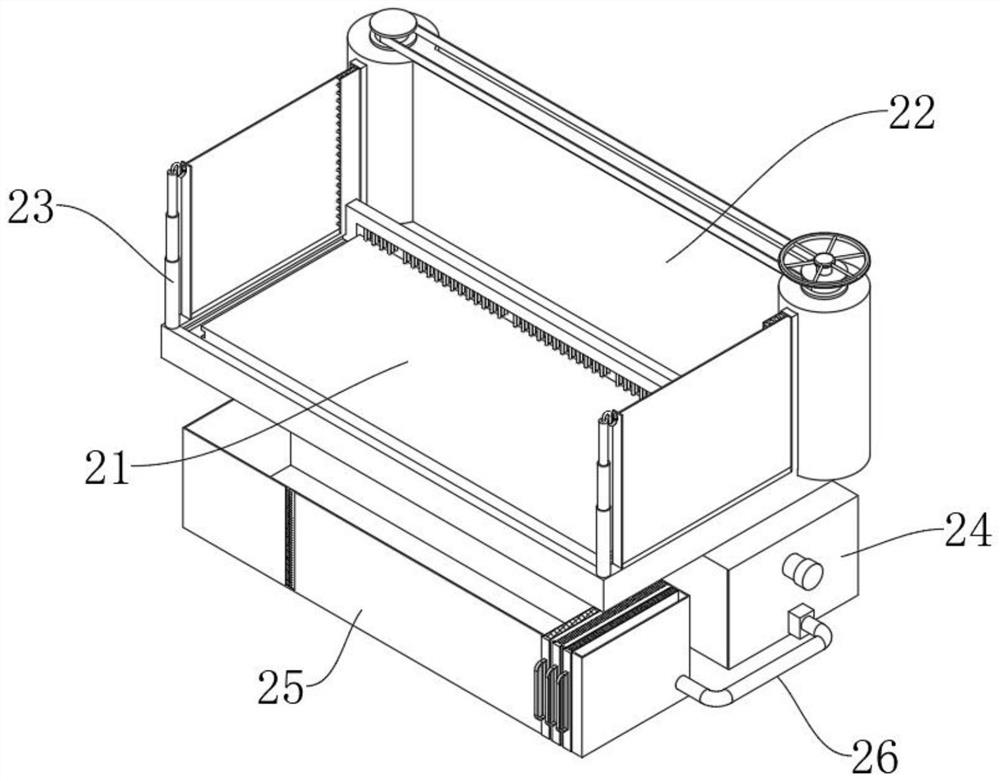

[0055] In this embodiment, the workbench 2 includes at least:

[0056] Platen 21, the top of the platen 21 is provided with a groove 211 near the edge, the inside of the groove 211 near the front surface is provided with a through groove 212, and the inside of the through groove 212 is provided with a filter screen 2120. By setting the filter screen 2120, large Particle residues fall from the inside of the through groove 212 to the inside of the collection box 251, which is inconvenient to clean, and both sides of the groove 211 are prov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com