An anti-dust grinding device for the production of lamp diffuser plates

A diffuser plate, dust-proof technology, applied in grinding/polishing safety devices, machine tools suitable for grinding workpiece edges, grinders, etc. Manpower saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

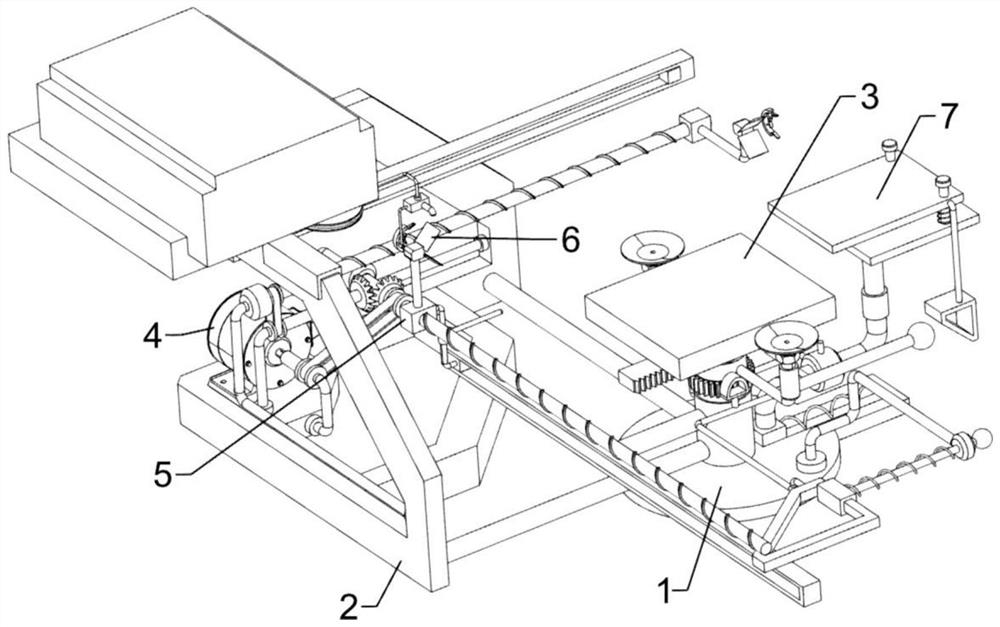

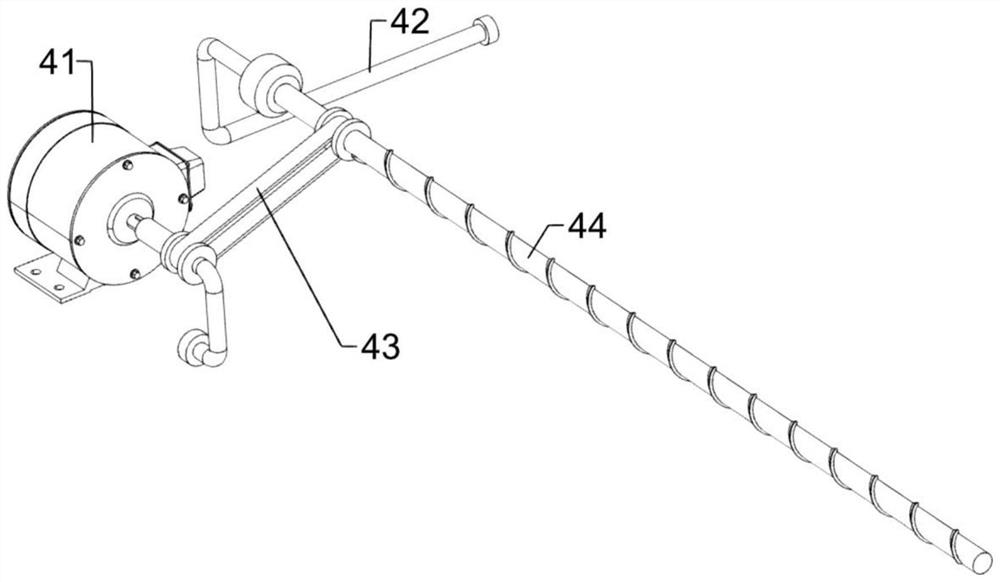

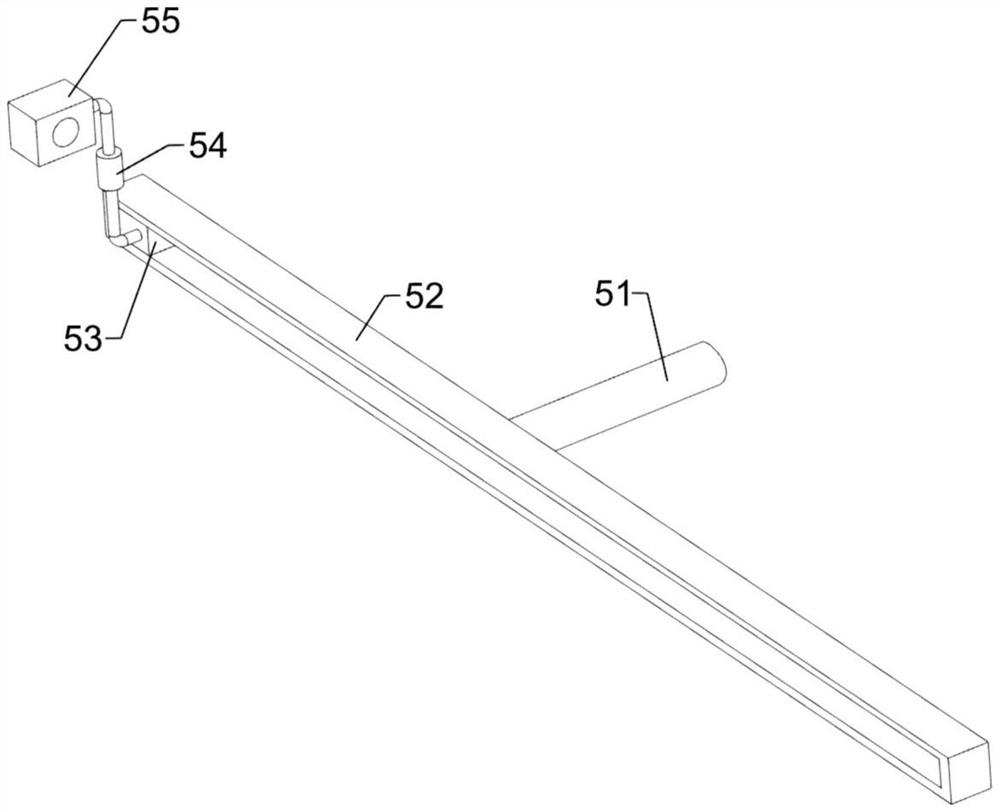

[0030] An anti-dust grinding device for the production of lamp diffusion plates, such as Figure 1-5 As shown, it includes a base 1, a frame 2, a placement plate 3, a drive assembly 4, a moving assembly 5, a grinding assembly 6 and a fixing assembly 7. The rear left side of the base 1 is connected to the frame 2, and the upper side of the base 1 The rotating type is equipped with a placement plate 3, the frame 2 is provided with a driving assembly 4, the driving assembly 4 is provided with a moving assembly 5, the moving assembly 5 is provided with a grinding assembly 6, and the right side of the base 1 is slidingly provided with a fixed assembly 7 .

[0031] When the lamp diffusion plate needs to be polished, the lamp diffusion plate is placed on the placement plate 3, and then the fixing component 7 is controlled to fix the lamp diffusion plate, and then the driving component 4 is started, and the driving component 4 will drive the moving component 5 to operate. Then, the p...

Embodiment 2

[0041] On the basis of Example 1, such as Figure 6 , Figure 7 , Figure 8 and Figure 9 As shown, it also includes a bevel gear combination 8, a rotating shaft 9 and a second flat belt combination 10, the rear side of the frame 2 is rotatably connected with a rotating shaft 9, and a bevel gear combination is connected between the rotating shaft 9 and the screw mandrel 44 on the left side. 8. A second flat belt assembly 10 is connected between the screw rod 44 on the rear side and the rotating shaft 9 .

[0042] Starting the motor 41 will drive the screw mandrel 44 on the left side to rotate, and then the rotating shaft 9 will be rotated through the bevel gear combination 8, and then the second flat belt combination 10 will be used to drive the screw mandrel 44 on the rear side to rotate, so that the device can simultaneously Grinding the two sides of the diffuser plate of the lamp saves the time of grinding and improves the production efficiency.

[0043] Also include th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com