Carbon-based sulfide composite photocatalyst, and preparation method and application thereof in degradation of heavy metals

A technology of sulfide and compound light, which is applied in the field of photocatalysis, can solve the problems of photocatalytic materials with two-dimensional nano flower-like structure, and achieve good stability, improved response and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

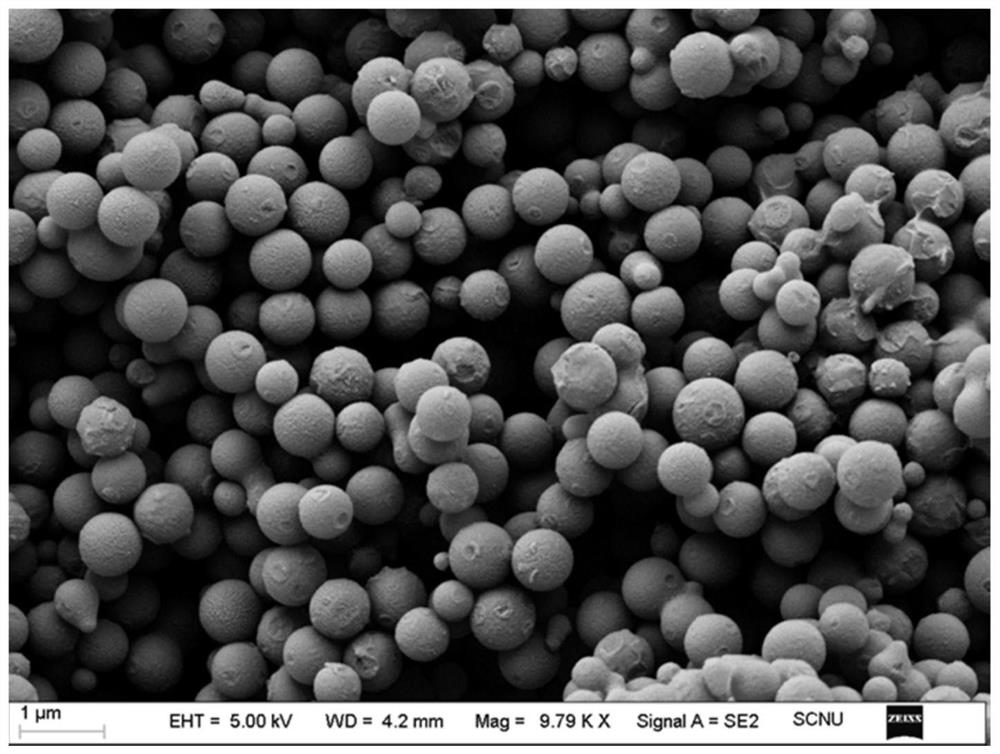

[0073] (1) Preparation of carbon spheres Cs

[0074] Weigh 6.16g of sucrose, dissolve the sucrose in 60ml of deionized water, stir it magnetically for 30min, put it into the reaction kettle, the reaction condition is 180°C, keep it warm for 4h, then wash it with deionized water and alcohol, and dry it to dryness Collect to get Cs.

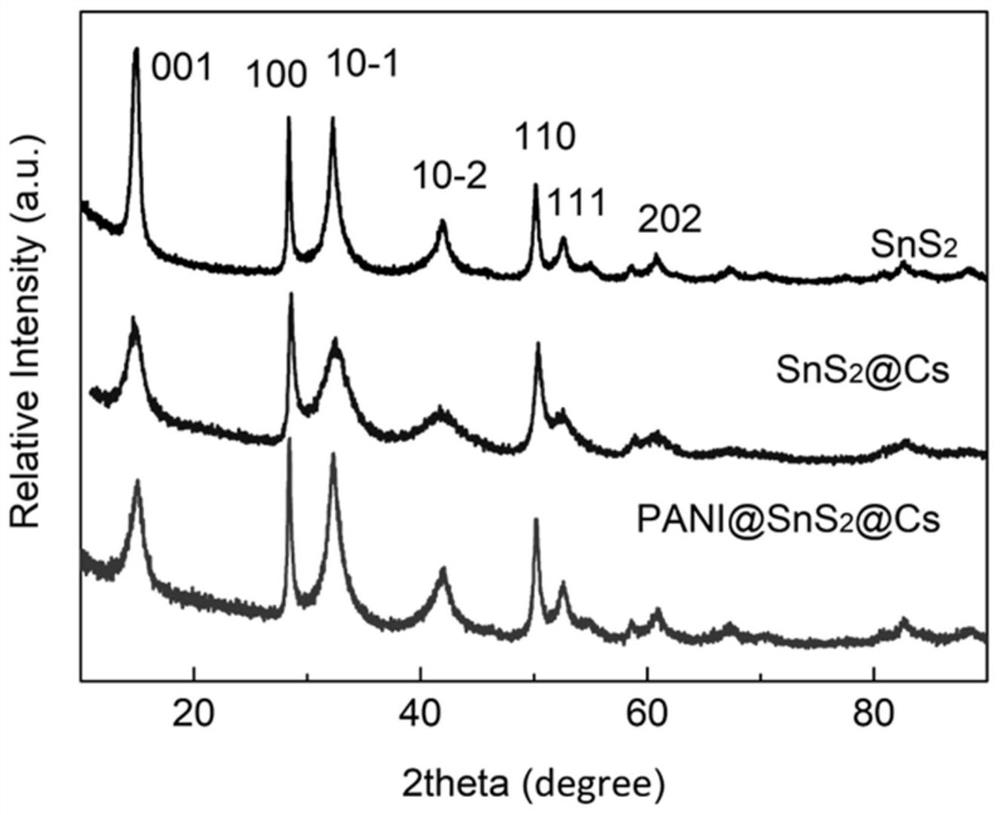

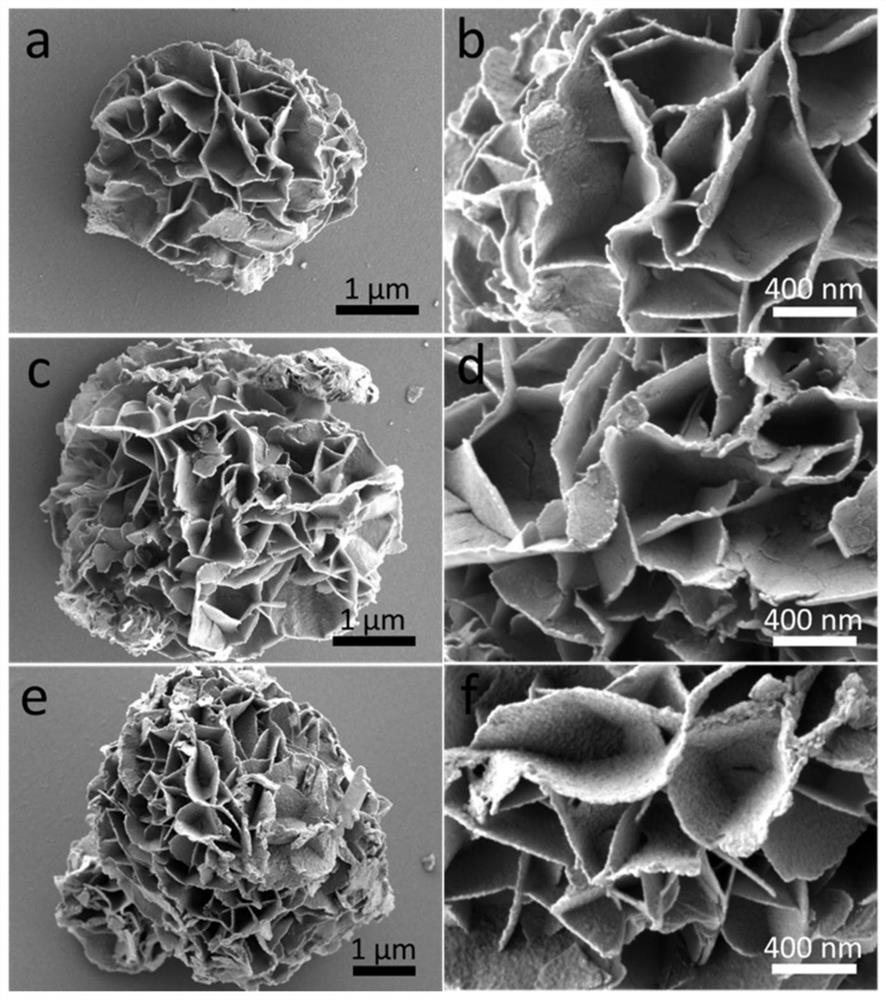

[0075] (2) Preparation process material SnS 2 @Cs

[0076] Add 0.1g of Cs into 20ml of absolute ethanol and sonicate for 1h, then weigh 1.745g of tin tetrachloride pentahydrate and 0.7513g of thioacetamide respectively and add them to the solution, then add 40ml of absolute ethanol and stir magnetically for 1h , and then put the solution into the reaction kettle, the reaction condition is 160°C, keep it warm for 6h, then wash it with deionized water and alcohol, and dry it at 60°C overnight to collect SnS 2 @Cs.

[0077] (3) Preparation of control material SnS 2

[0078] SnS 2 The preparation of is under the experimental condition of above-m...

Embodiment 2

[0082] (1) Preparation of carbon spheres Cs

[0083] Weigh 6.16g of sucrose, dissolve the sucrose in 60ml of deionized water, stir it magnetically for 30min, put it into the reaction kettle, the reaction condition is 180°C, keep it warm for 4h, then wash it with deionized water and alcohol, and dry it to dryness The obtained Cs was collected, and the obtained Cs was calcined in a tube furnace under nitrogen protection at a calcining temperature of 800° C., a heating rate of 4 min / ° C., and a heat preservation of 4 h. Calcined Cs is finally obtained.

[0084] (2) Preparation process material SnS 2 @Cs

[0085] Add 0.1g of Cs into 20ml of absolute ethanol and sonicate for 1h, then weigh 1.745g of tin tetrachloride pentahydrate and 0.7513g of thioacetamide respectively and add them to the solution, then add 40ml of absolute ethanol and stir magnetically for 1h , and then put the solution into the reaction kettle, the reaction condition is 160°C, keep it warm for 6h, then wash ...

Embodiment 3

[0091] (1) Preparation of carbon spheres Cs

[0092]Weigh 6.16g of sucrose, dissolve the sucrose in 60ml of deionized water and stir it magnetically for 30 minutes, then put it into the reaction kettle, the reaction condition is 160°C, keep it warm for 4 hours, then wash it with deionized water and alcohol, and dry it to dryness The obtained Cs was collected, and the obtained Cs was calcined in a tube furnace under nitrogen protection at a calcining temperature of 500° C., a heating rate of 2 min / ° C., and a heat preservation of 4 h. Calcined Cs is finally obtained.

[0093] (2) Preparation process material SnS 2 @Cs

[0094] Add 0.2g of Cs into 20ml of absolute ethanol and sonicate for 1h, then weigh 1.745g of tin tetrachloride pentahydrate and 0.7513g of thioacetamide respectively and add them into the solution, then add 40ml of absolute ethanol and stir magnetically for 1h , and then put the solution into the reaction kettle, the reaction condition is 160°C, keep it warm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com