Method for synthesizing 1,3-diiminoisoindoline by using mixed solvent

A bis-imino and mixed solvent technology, applied in the direction of organic chemistry, can solve the problems of insufficient raw materials in the phthalonitrile method and unstable reactions in the solid phase melting method, and achieve solutions to unstable reactions, insufficient raw materials, and high yields. Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

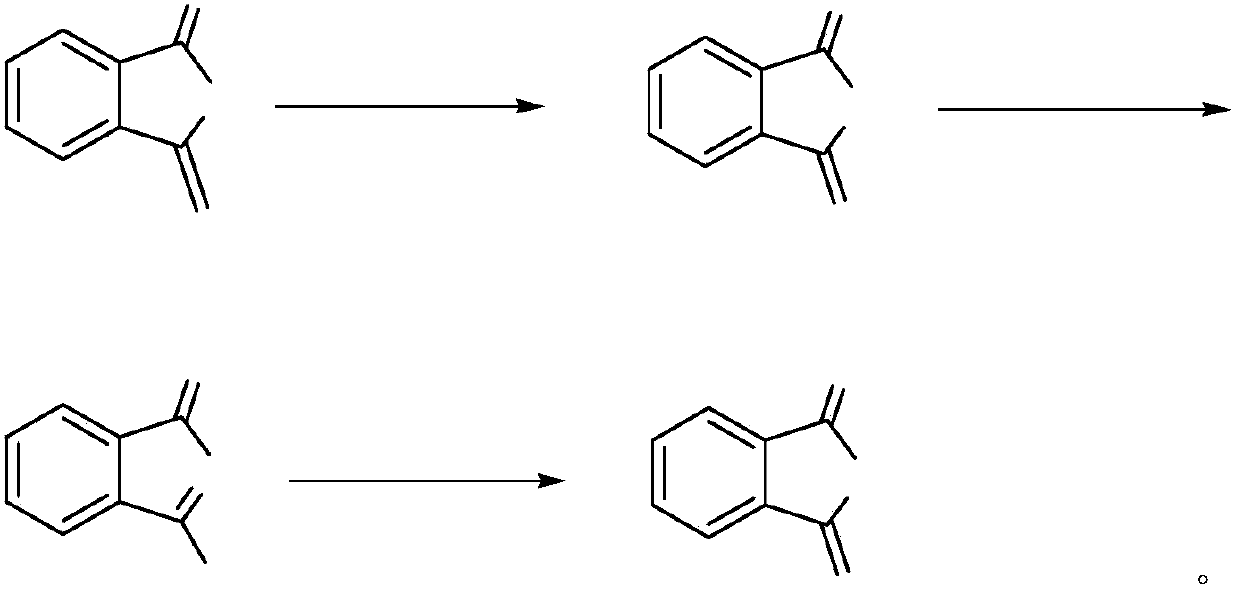

Method used

Image

Examples

Embodiment 1

[0022] Add phthalic anhydride and urea into 2000L xylene and mix according to the molar ratio of 7:3, raise the temperature to 132°C and keep it warm for 0.5h. After the water is separated, start to evaporate the solvent. Cooling and suction filtration to obtain solid phthalimide;

[0023] Throw phthalimide, urea, ammonium nitrate, and ammonium molybdate into 2000L of dichlorobenzene at a molar ratio of 100:300:124:1, and heat up to above 150°C for 2 hours after the reaction. Evaporate the solvent, after the solvent is evaporated, cool down to below 110°C, add a certain amount of water, stir, cool down and suction filter to obtain the wet product nitrate;

[0024] Add a certain amount of water to the wet product nitrate and beat for more than 20 minutes. After beating, add liquid caustic soda with a mass fraction of 30% at room temperature. The mass ratio of wet product nitrate, water and liquid caustic soda is 13:15:12. Clear to the process of product precipitation, stir for...

Embodiment 2

[0026] Add phthalic anhydride and urea to 2000L of methanol according to the molar ratio of 5:3 and mix them. Raise the temperature to 132°C and keep it warm for 0.5h. After the water is separated, start to evaporate the solvent. Suction filtration obtains solid phthalimide;

[0027] Put phthalimide, urea, ammonium nitrate, and ammonium molybdate in a molar ratio of 100:300:124:1 into a mixed solvent of 2000L methyl acetate and ethanol, and heat up to above 150°C for reaction After 2 hours, evaporate the solvent after the reaction is completed. After the solvent is evaporated, cool down to below 110°C, add a certain amount of water, stir and cool down, and suction filter to obtain the wet product nitrate;

[0028] Add a certain amount of water to the wet product nitrate and beat for more than 20 minutes. After beating, add liquid caustic soda with a mass fraction of 30% at room temperature. The mass ratio of wet product nitrate, water and liquid caustic soda is 13:15:12. Clea...

Embodiment 3

[0030] Add phthalic anhydride and urea into the mixed solvent of 2000L ethyl acetate and benzene according to the molar ratio of 6:3 and mix evenly, raise the temperature to 132°C and keep it warm for 0.5h. After the water is separated, start to evaporate the solvent, and cool down after evaporation Add water to 100°C and stir, cool down and filter with suction to obtain solid phthalimide;

[0031] Put phthalimide, urea, ammonium nitrate, and ammonium molybdate in a molar ratio of 100:300:124:1 into a mixed solvent of 2000L toluene and methanol. After the reaction, the solvent is evaporated, and after the solvent is evaporated, the temperature is lowered to below 110°C, a certain amount of water is added, the temperature is stirred, the temperature is lowered and the suction is filtered, and the wet product nitrate is obtained;

[0032] Add a certain amount of water to the wet product nitrate and beat for more than 20 minutes. After beating, add liquid caustic soda with a mass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com