Tea-leaf twisting machine

A technology for rolling machine and tea leaves, applied in the field of tea rolling machine, can solve the problems of affecting the quality of tea leaves and unfavorable formation of the upper tea leaves (clumping, failure of the pressing plate to work properly, etc.)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

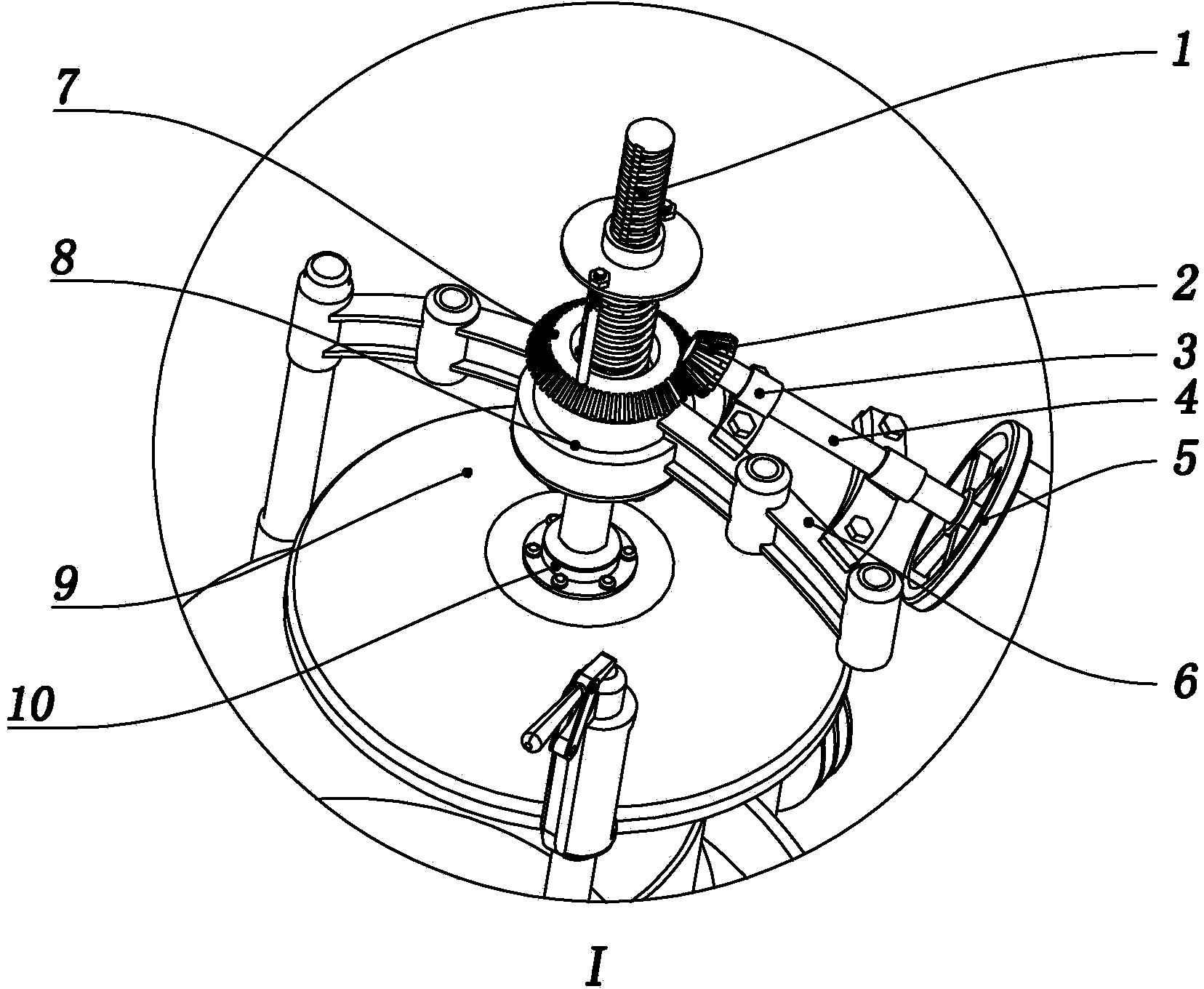

[0028] refer to Figure 1 to Figure 7 Shown, a kind of tea kneading machine comprises its pressurizing device, kneading disc 18 and kneading bucket 17, and pressurizing device comprises bent frame, small bevel gear 2, big bevel tooth seat 7, nut 11 and screw rod 1, and curved frame comprises Two curved arms 6 and the curved frame seat 8 connecting the two curved arms 6, the small bevel gear 2 is connected to the pressurized hand wheel 5 through the hand wheel shaft 4, the hand wheel shaft 4 is fixed to the curved arm 6 through the shaft seat 3, the small bevel gear 2 Mesh transmission with the large bevel tooth seat 7, the screw 1 and the nut 11 constitute a screw transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com