Washing machine and control method thereof

A technology for washing machines and inner drums, which is applied to the control device of washing machines, other washing machines, washing devices, etc. It can solve the problems of disparity, low success rate of dehydration, waste of water resources, etc., and achieve the effect of reducing water content and light weight of the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] The washing machine described in this embodiment includes an inner tub for storing loads to be washed. An eccentric member is arranged on the wall of the inner cylinder, and the eccentric member can absorb water to increase its weight, and the rotation speed of the inner cylinder can be greater than the set rotation speed V 0 Lose water and lose weight.

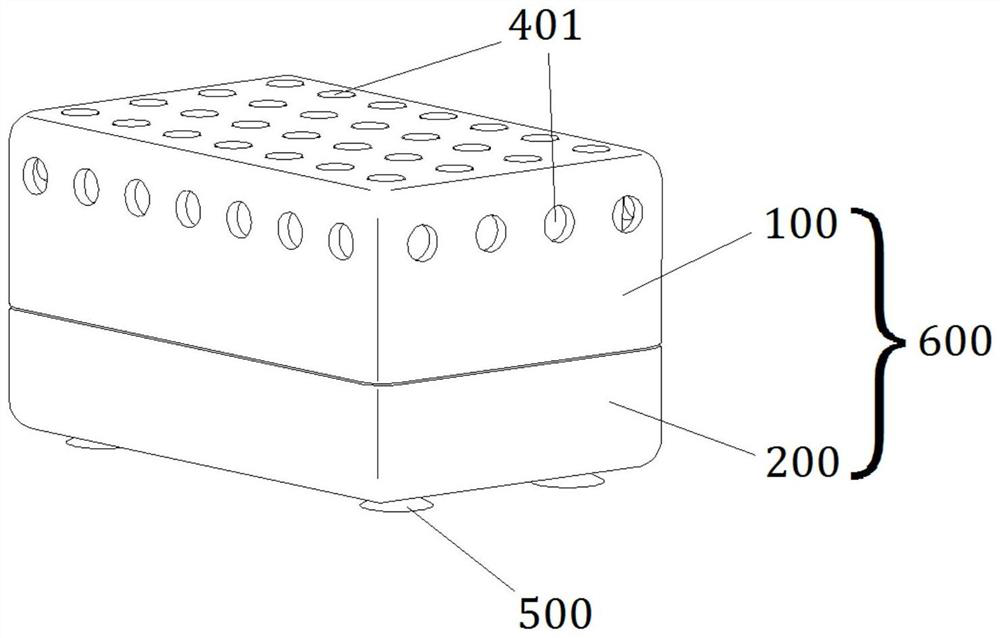

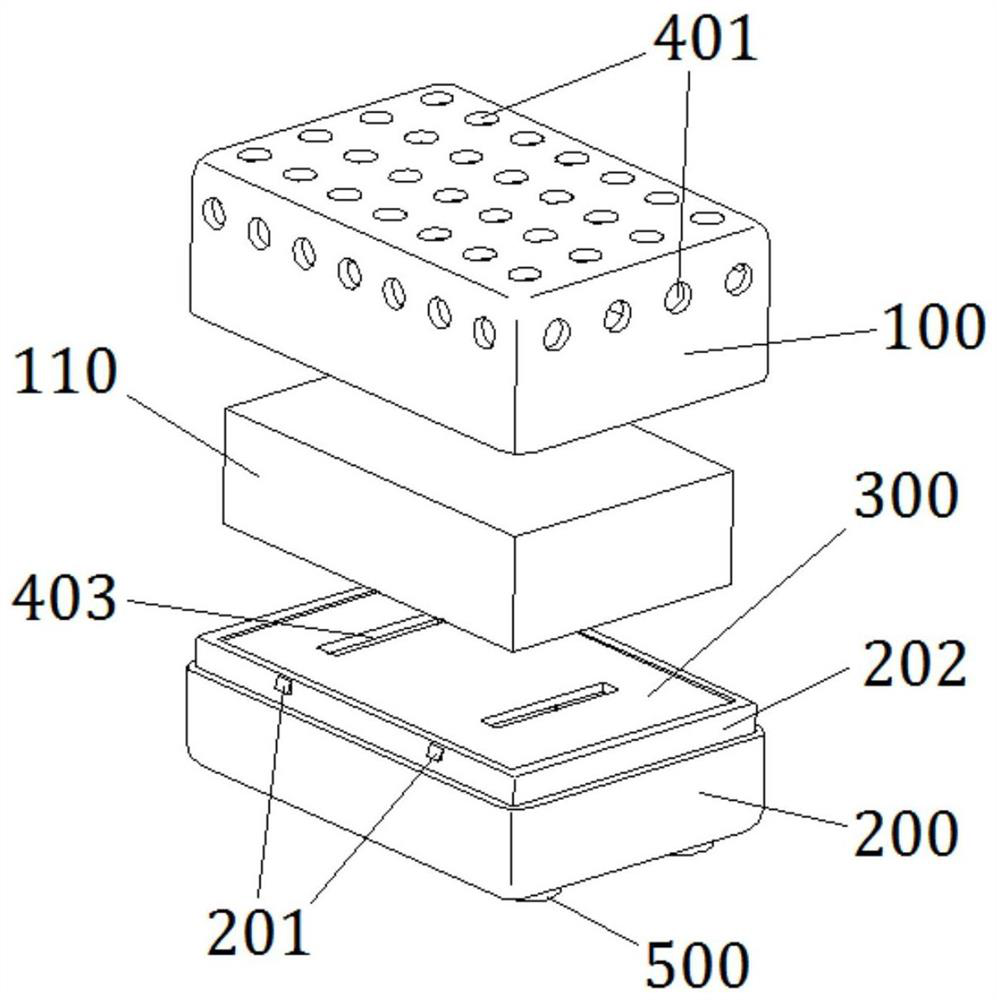

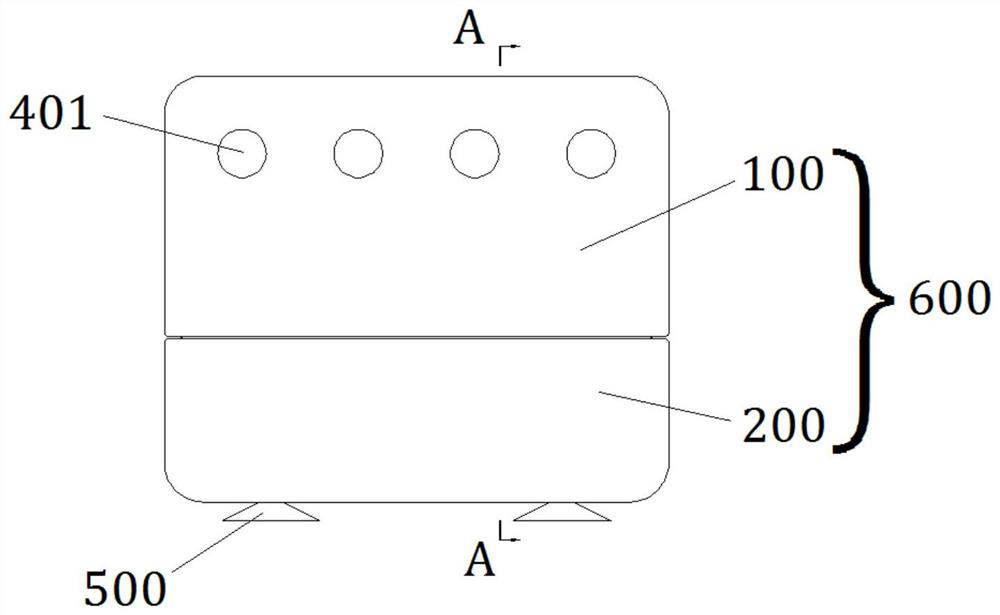

[0067] like Figure 1 to Figure 8 As shown, in this embodiment, the eccentric member includes a housing 600 with a hollow chamber and a water-absorbing member 110 arranged inside the housing 600. Several water inlet holes 401 are provided on the housing 600, and the water-absorbing member 110 can absorb water to increase own weight.

[0068] In this embodiment, the water-absorbing member 110 is a water-absorbable material with a specific water absorption rate, such as a water-absorbing sponge.

[0069] Further, inside the housing 600 there is a partition plate 300 arranged perpendicular to the radial direction of th...

Embodiment 2

[0103] like Figure 9 As shown, this embodiment provides a control method for the washing machine described in the first embodiment above, the washing machine has a small-load dehydration program, and the small-load dehydration program specifically includes the following steps:

[0104] S1, the washing machine detects the eccentric value of the inner cylinder, and the eccentric value of the inner cylinder is less than L 1 , control the speed of the inner cylinder to rise to V 1 and last for a certain period of time;

[0105] S2, control the inner cylinder to reduce the speed and detect the eccentric value, the eccentric value of the inner cylinder is less than L 2 , control the speed of the inner cylinder to rise to V 2 and last for a certain period of time;

[0106] S3, control the inner cylinder to reduce the speed and detect the eccentric value, the eccentric value of the inner cylinder is less than the preset eccentric value L 0 , control the speed of the inner cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com