A method for separating rare and precious metals based on floatation extraction system

A rare and precious metal extraction technology, applied in the direction of solid separation, flotation, process efficiency improvement, etc., can solve the problems of lengthy operation process, etc., and achieve the effect of overcoming low separation efficiency, less solvent consumption and good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

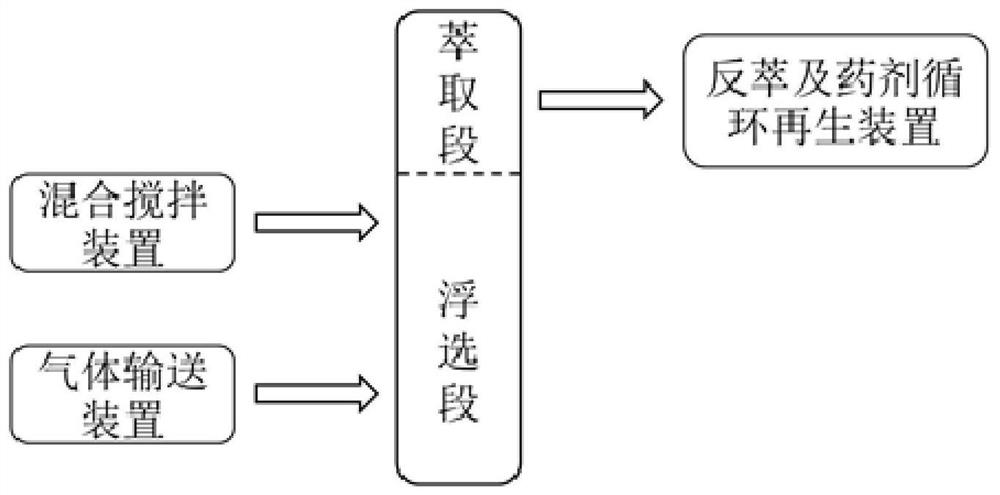

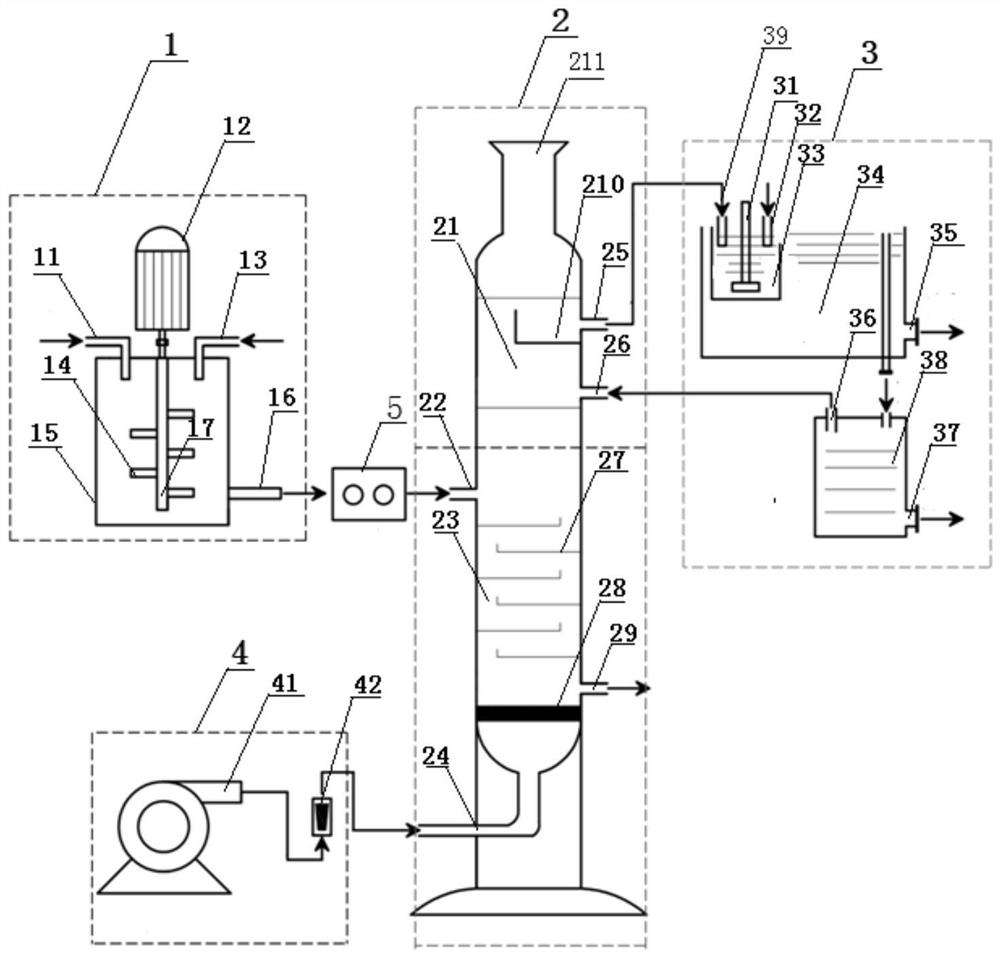

Method used

Image

Examples

Embodiment 1

[0037] Separation of dissolved niobium and tantalum based on a planktonic extraction system, the process is as follows:

[0038] (1) The solution containing 1g / L of tantalate and 1g / L of niobate is added to the mixing and stirring device at a speed of 10ml / min, and at the same time, the selective flotation agent (from 60% ten to ten) is continuously added to the mixing and stirring device Hexaalkyl trimethyl ammonium bromide and 40% P507 compound), and the molar ratio of flotation agent and tantalate is constant at 2, and the fixed stirring speed is 600r / min to form a tantalate-agent hydrophobic complex.

[0039] (2) The mixed solution in the mixing and stirring device is transported to the flotation extraction device at a speed of 12ml / min by the peristaltic pump, the gas flow meter is adjusted, and the gas speed is controlled to be 60ml / min, so that the mixed solution and the bubbles are in countercurrent contact in the flotation section , the hydrophobic complex floats up i...

Embodiment 2

[0044] Based on a planktonic extraction system to separate dissolved platinum and rhodium, the process is as follows:

[0045] (1) the acid leaching solution containing chloroplatinate 200mg / L, chlororhodium 100mg / L is added to the mixing and stirring device at a speed of 10ml / min, and simultaneously in the mixing and stirring device, the selective flotation agent ( It is composed of 40% quaternary ammonium salt N263 and 60% primary amine N1923), and the molar ratio of flotation reagent and platinum is kept constant at 2, and the fixed stirring speed is 600r / min to form a chloroplatinate-agent hydrophobic complex.

[0046] (2) The mixed solution in the mixing and stirring device is transported to the flotation extraction device at a speed of 12ml / min by the peristaltic pump, the gas flow meter is adjusted, and the gas speed is controlled to be 80ml / min, so that the mixed solution and the bubbles are in countercurrent contact in the flotation section , the hydrophobic complex f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com