High-density modified plastic particle cooling device

A plastic granule and cooling device technology, applied in the field of plastic cooling, can solve the problems of incomplete cooling and plastic granule quality degradation, and achieve the effects of uniform cooling, reduced workload, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

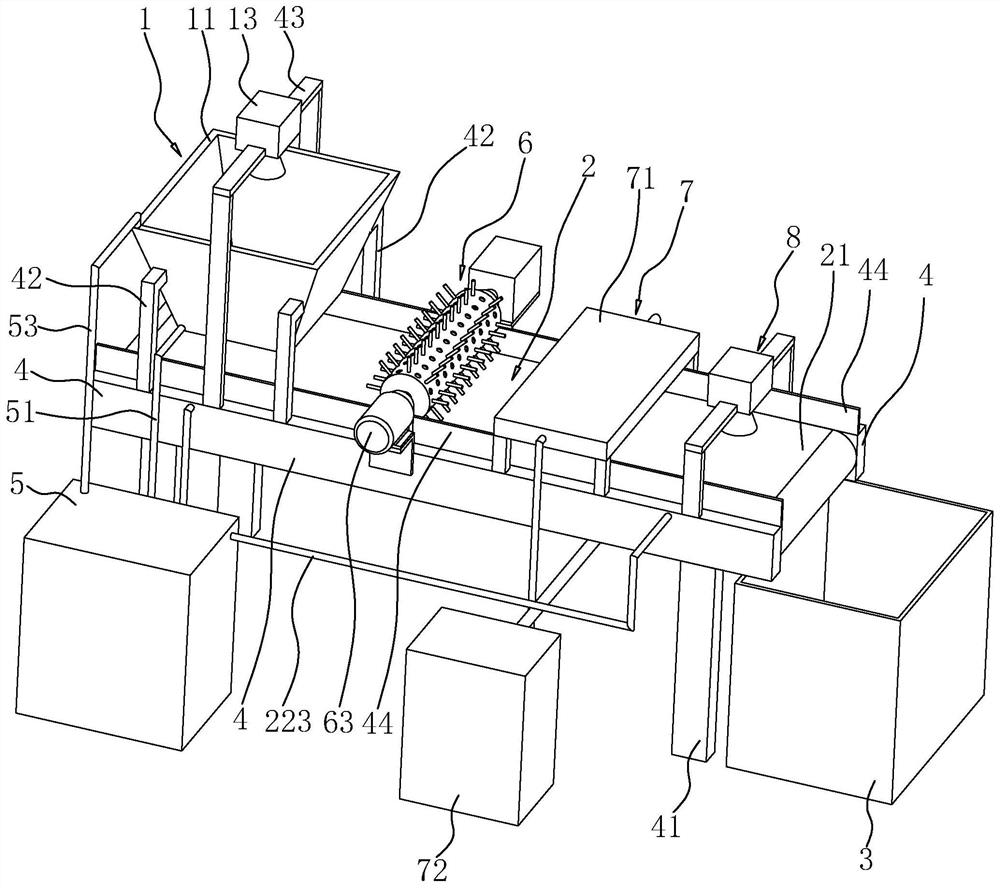

[0038] The following is attached Figure 1-5 The application is described in further detail.

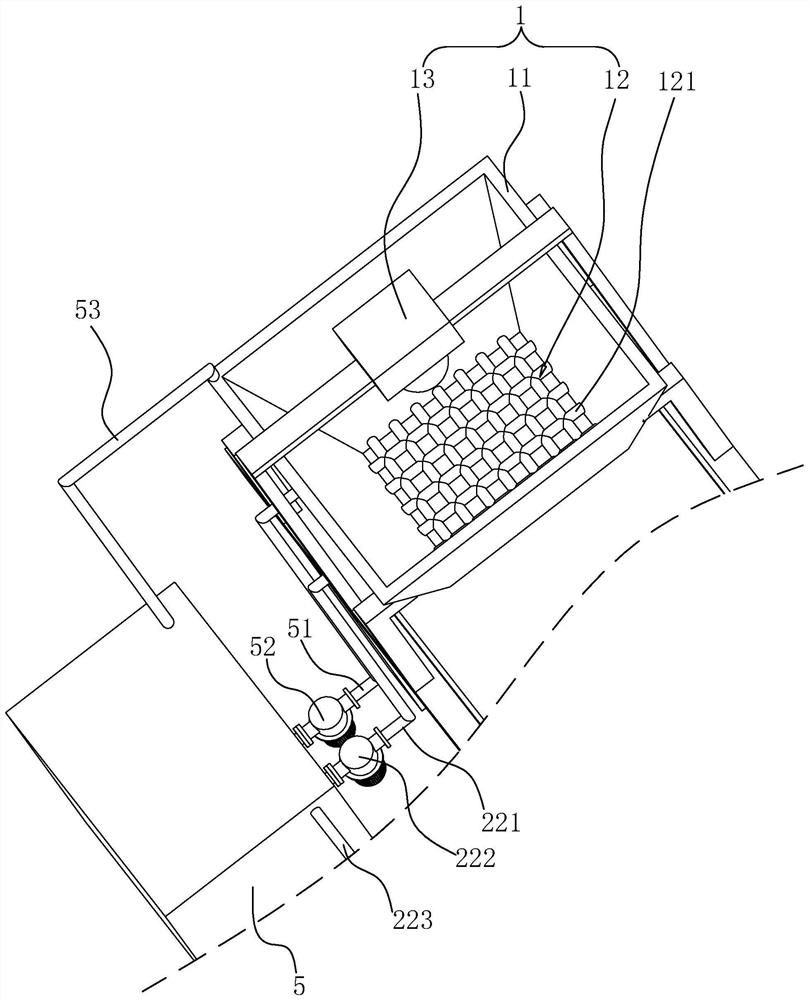

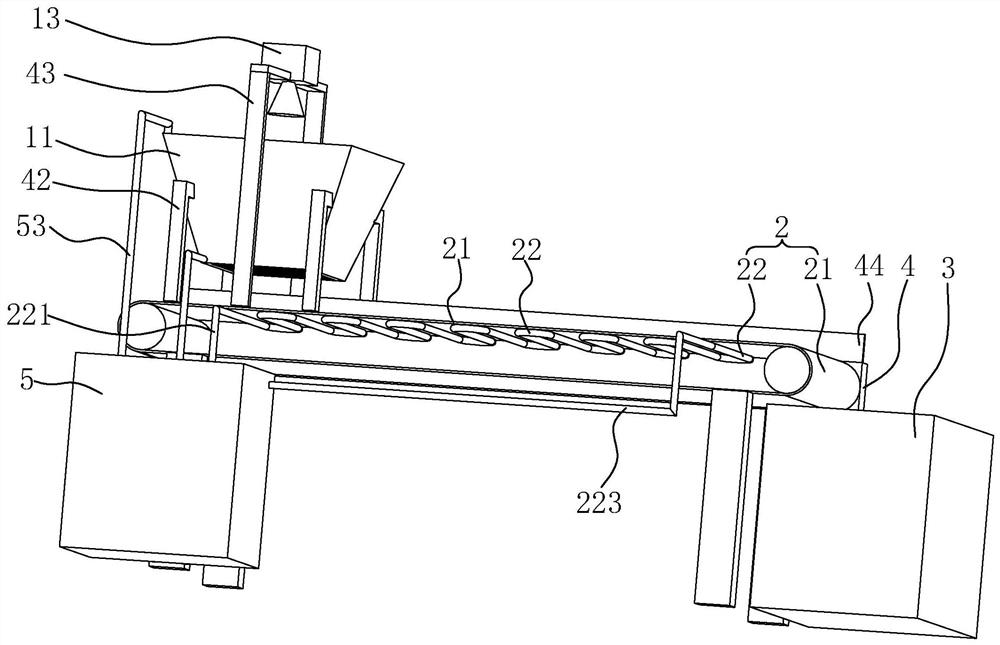

[0039] The embodiment of the present application discloses a cooling device for high-density modified plastic particles. refer to figure 1 The cooling device for high-density modified plastic particles includes a first cooling assembly 1 and a conveying assembly 2, the first cooling assembly 1 is located above the conveying assembly 2, and the end of the conveying assembly 2 away from the first cooling assembly 1 is provided with a collection box 3 for collecting The upper end surface of the box 3 is lower than the conveying assembly 2 . The plastic granules produced by the plastic granulator enter from the first cooling assembly 1 , and then fall on the conveying assembly 2 , and the conveying assembly 2 conveys the cooled plastic granules to the collection box 3 .

[0040] refer to figure 1 and figure 2 , the first cooling assembly 1 includes a feed hopper 11 , a cooling net ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com