Single-end reflective long-period fiber grating sensor and manufacture process thereof

A fiber grating and manufacturing process technology, applied in the direction of converting sensor output, using optical devices to transmit sensing components, instruments, etc., can solve the problems of expensive and bulky instruments, inconvenient monitoring of transmission-type long-period fiber gratings, etc., and achieve high sensing sensitivity , easy adhesion and adhesion, simple coating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

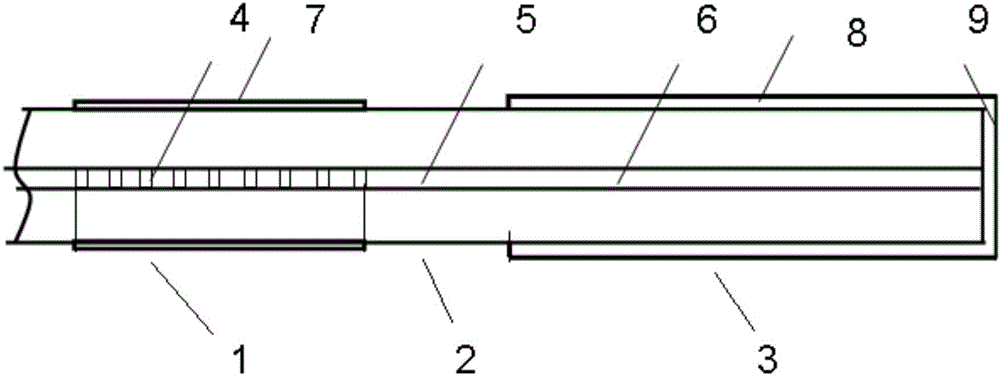

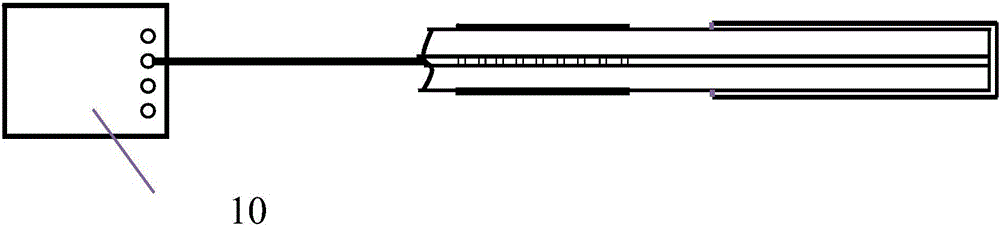

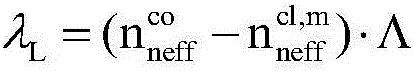

[0039] combine Figure 1-2 , a long-period fiber grating sensor based on single-end reflection, including long-period fiber grating segment 1, fiber segment 2 and tail end segment 3, from left to right are long-period fiber grating segment 1, fiber segment 2 and tail end Section 3, the length of the fiber grating section 1 is 4-6cm, the length of the fiber section 2 is 1-2cm, and the length of the tail end section 3 is 1-6cm.

[0040] The fiber grating segment 1 is sequentially composed of fiber grating segment core 4 and fiber grating segment metal film 7 from the inside to the outside. A layer of fiber grating segment metal film 7 is arranged on the surface of the long period fiber grating segment 1. On the surface of the tail end segment 3 There is a layer of end-section metal film 8, and a layer of end-section metal film 9 is provided on the end surface of the end-end section 3. The end-end section 3 is followed by the end-section fiber core 6 and the end-end section metal...

Embodiment 2

[0049] This embodiment is similar to Embodiment 1, wherein the fiber grating segment 1 of the sensor has a length of 4 cm, the fiber segment 2 has a length of 1 cm, and the tail end segment 3 has a length of 1 cm. The metal film 7 of the fiber grating segment has a thickness of 50 nm, and the metal film 8 of the tail end segment and the metal film 9 of the end face of the tail end segment have a thickness of 700 nm.

[0050] A manufacturing process based on a single-ended reflective long-period fiber grating sensor, the steps of which are:

[0051] A. Flattening one end of the LPFG to form LPFG segment 1 and fiber segment 2;

[0052] B. Inside the long-period fiber grating segment 1 is the fiber grating segment core 4, and a layer of fiber grating metal film 7 is coated on the surface of the long-period fiber grating segment 1, and the surface of the long-period fiber grating forms a plasmon resonance effect; the fiber grating segment metal The thickness of film 7 is 50nm;

...

Embodiment 3

[0057] This embodiment is similar to Embodiment 1, wherein the fiber grating segment 1 of the sensor has a length of 6 cm, the fiber segment 2 has a length of 2 cm, and the tail end segment 3 has a length of 6 cm. The metal film 7 of the fiber grating segment has a thickness of 100 nm, and the metal film 8 of the tail end segment and the metal film 9 of the end face of the tail end segment have a thickness of 1000 nm.

[0058] A manufacturing process based on a single-ended reflective long-period fiber grating sensor, the steps of which are:

[0059] A. Flattening one end of the LPFG to form LPFG segment 1 and fiber segment 2;

[0060] B. Inside the long-period fiber grating segment 1 is the fiber grating segment core 4, and a layer of fiber grating metal film 7 is coated on the surface of the long-period fiber grating segment 1, and the surface of the long-period fiber grating forms a plasmon resonance effect; the fiber grating segment metal The thickness of the film 7 is 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com