Integrated production and processing equipment for fine grinding and stirring of titanium dioxide raw materials

A processing equipment and titanium dioxide technology, which is applied in the field of integrated production and processing equipment for fine grinding, stirring and processing of titanium dioxide raw materials, can solve the problems of single function type of titanium dioxide, and achieve the advantages of improving stirring and grinding efficiency, saving material resources and reducing production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

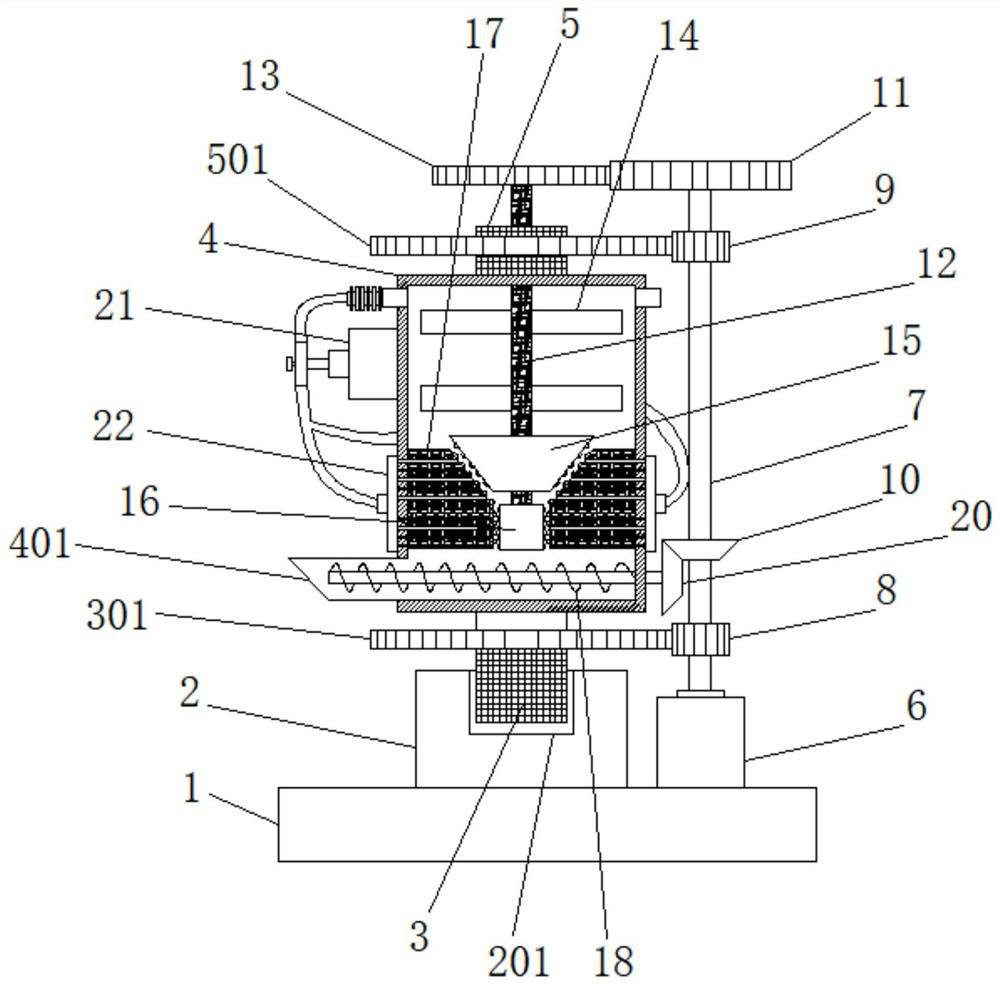

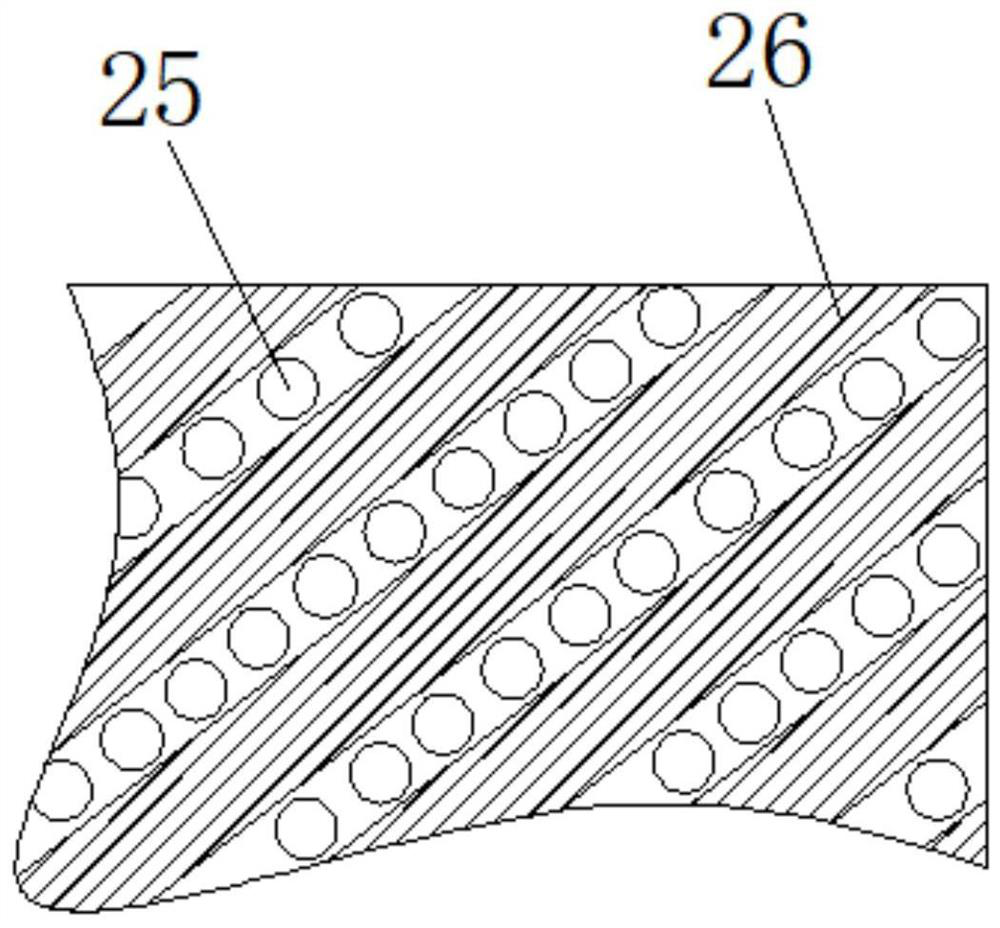

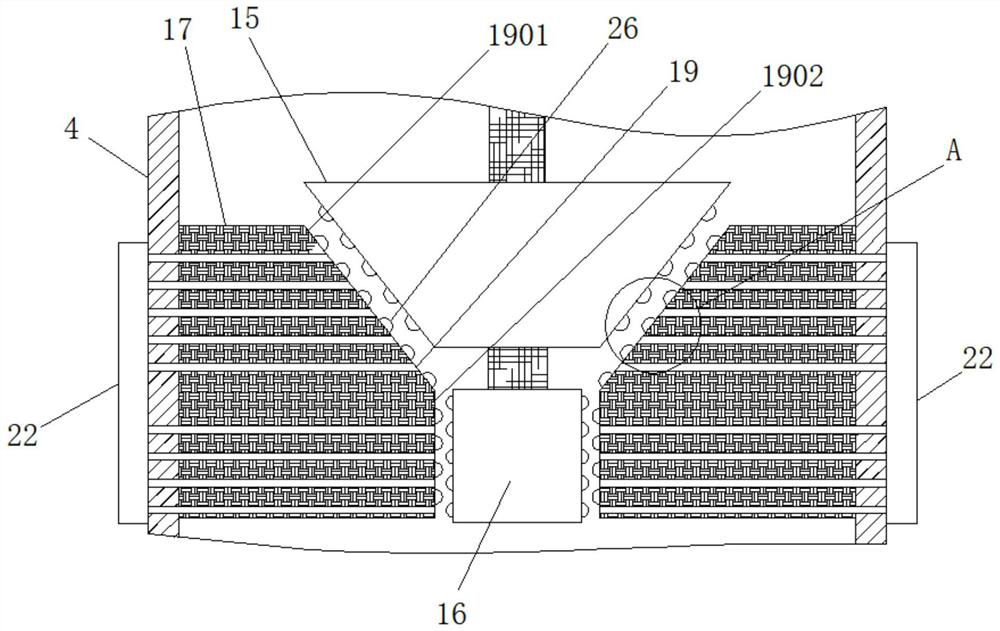

[0025] see Figure 1-5 , an integrated production and processing equipment for fine grinding, stirring and processing of titanium dioxide raw materials, including a base 1 and a motor 6, a stable seat 2 is provided at the top of the base 1, and a No. The top of the processing box 4 is provided with a processing box 4, and the top of the processing box 4 is provided with a No. 2 connector 5. The outer walls of the No. 1 connector 3 and the No. 2 connector 5 are respectively nested with a No. 1 gear 301 and a No. 2 gear 501. The motor 6 The output end of the rotating rod 7 is provided with a rotating rod 7, and the outer wall of the rotating rod 7 is respectively nested with the third gear 8, the fourth gear 9 and the first connecting gear 10, the top of the rotating rod 7 is provided with the fifth gear 11, the first gear 301 The No. 3 gear 8 is in meshing connection, the No. 2 gear 501 is in meshing connection with the No. 4 gear 9, the No. 2 connecting piece 5 penetrates the ...

Embodiment 2

[0032] On the basis of Example 1, please refer to Figure 1-5, an integrated production and processing equipment for fine grinding, stirring and processing of titanium dioxide raw materials, including a base 1 and a motor 6, a stable seat 2 is provided at the top of the base 1, and a No. The top of the processing box 4 is provided with a processing box 4, and the top of the processing box 4 is provided with a No. 2 connector 5. The outer walls of the No. 1 connector 3 and the No. 2 connector 5 are respectively nested with a No. 1 gear 301 and a No. 2 gear 501. The motor 6 The output end of the rotating rod 7 is provided with a rotating rod 7, and the outer wall of the rotating rod 7 is respectively nested with the third gear 8, the fourth gear 9 and the first connecting gear 10, the top of the rotating rod 7 is provided with the fifth gear 11, the first gear 301 The No. 3 gear 8 is in meshing connection, the No. 2 gear 501 is in meshing connection with the No. 4 gear 9, the No...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com