Preparation method and application of hierarchical pore SAPO-11 molecular sieve and long-chain alkane isomerization catalyst

A technology of SAPO-11 and molecular sieves, applied in molecular sieve catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of SAPO-11 molecular sieves with large grain size, complicated preparation process and low isomerization activity, etc. Achieve the effects of improving mass transfer performance, reducing diffusion resistance, increasing activity and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

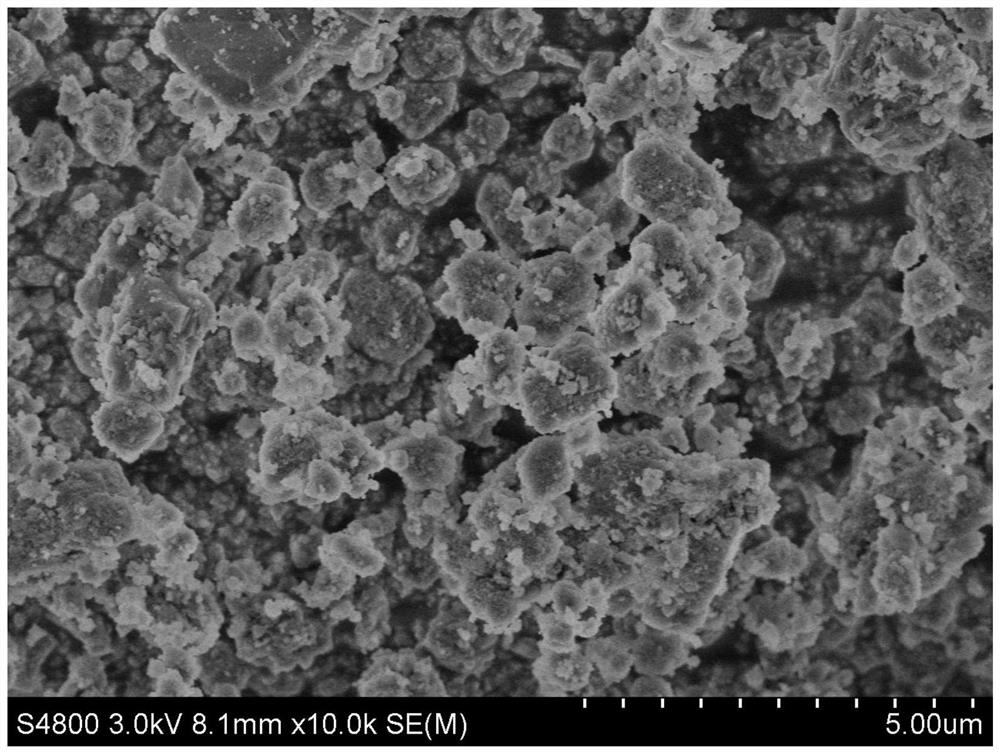

no. 1 example

[0045] A preparation method for a long-chain alkane isomerization catalyst, comprising the steps of:

[0046] (1) Add 1250g of water, 85g of methanol, 20.0g of PMMA with a particle size of 10-30μm, and 10.0g of C 16-2-16 Gemini surfactant ethylene-bis(hexadecyldimethylammonium chloride) and 238g pseudoboehmite (Al 2 o 3 Content 72%, mass percentage) and mix uniformly; then mix 387.5g phosphoric acid (85%, mass percentage) and 400g water and drop in the aforementioned emulsion, dropwise add and stir 4h; Then dropwise add templating agent di-n-propylamine 170.0g, stir 2h, then dropwise add 101g of silica sol (SiO 2 Content 30%, mass percentage), stirred for 4 hours, loaded into a kettle, crystallized at 200°C for 48 hours, then centrifuged, washed, dried overnight at 120°C, and calcined at 550°C for 24 hours to obtain a multi-order porous SAPO-11 molecular sieve.

[0047] (2) Take by weighing 140 g of the multi-stage porous SAPO-11 molecular sieve and 60 g of pseudo-boehmite ...

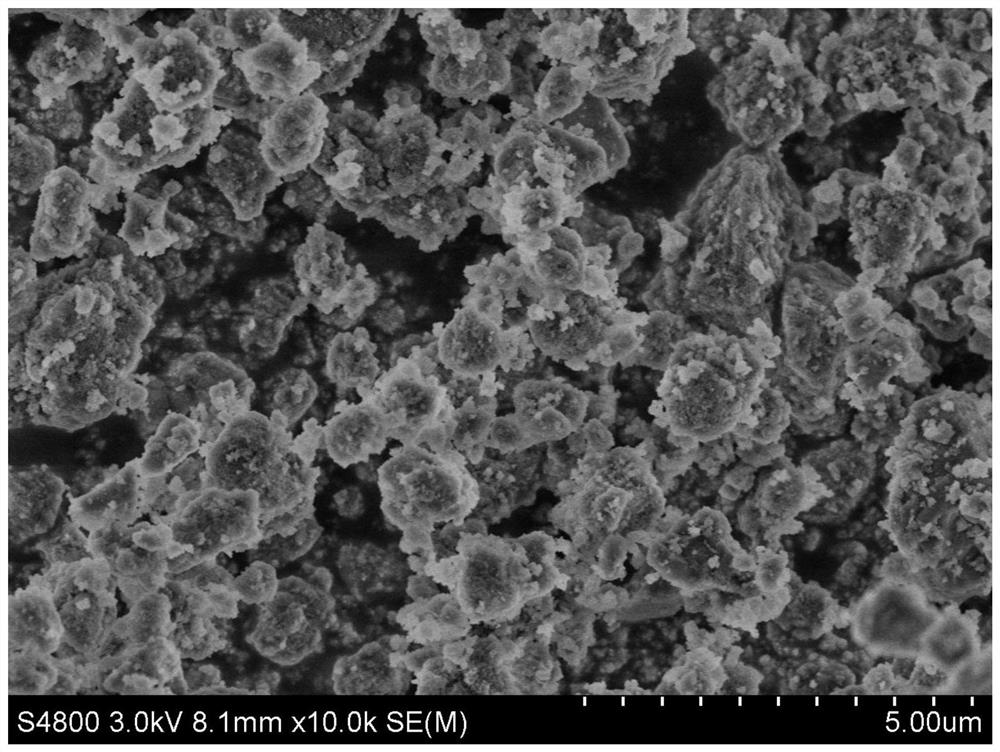

no. 2 example

[0050] A preparation method for a long-chain alkane isomerization catalyst, comprising the steps of:

[0051] (1) Add 1250g of water, 75g of ethanol, 30.0g of PMMA with a particle size of 5-30μm, and 2.5g of C 12-3-12 The Gemini surfactant propylene-bis(dodecyldimethylammonium chloride) and 238g pseudoboehmite (Al 2 o 3 Content 72%, mass percentage) and mix uniformly; then mix 387.5g phosphoric acid (85%, mass percentage) and 400g water and drop in the aforementioned emulsion, dropwise add and stir 4h; Then dropwise add templating agent di-n-propylamine 170.0g, stir 4h, then dropwise add 101g of silica sol (SiO 2 Content 30%, mass percentage), stirred for 2 hours, loaded into a kettle, crystallized at 200°C for 48 hours, then centrifuged, washed, dried overnight at 120°C, and calcined at 600°C for 24 hours to obtain a multi-order porous SAPO-11 molecular sieve.

[0052] (2) Take by weighing 140 g of the multi-stage porous SAPO-11 molecular sieve prepared in the present embo...

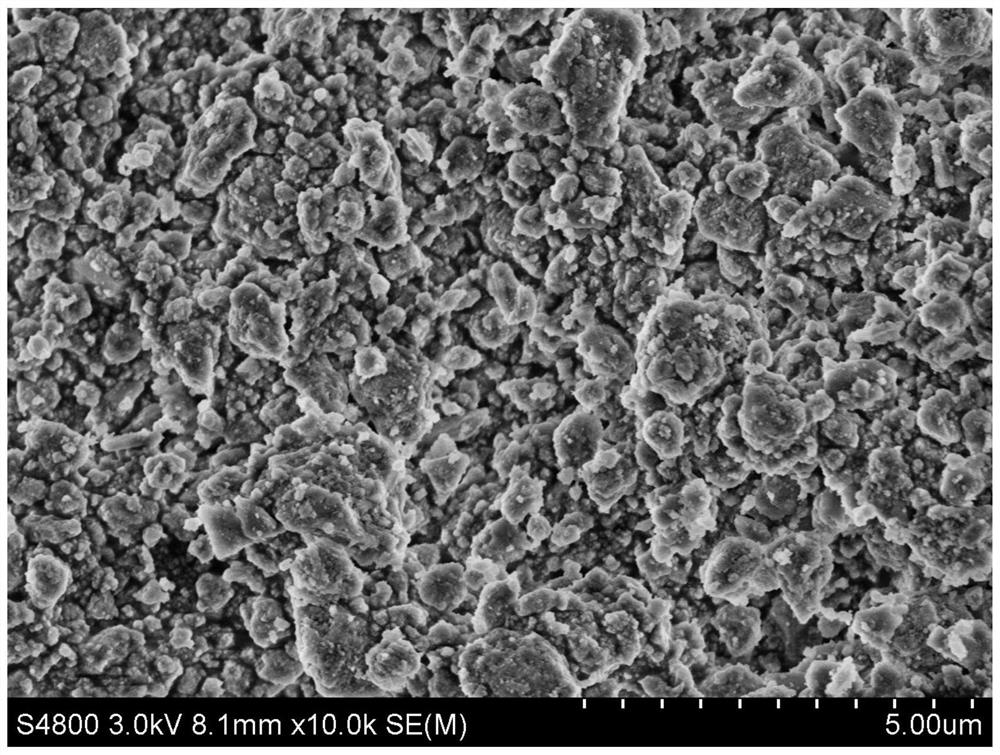

no. 3 example

[0055] A preparation method for a long-chain alkane isomerization catalyst, comprising the steps of:

[0056] (1) Add 1250g of water, 80g of propanol, 15.0g of PMMA with a particle size of 5-20μm, and 2.0g of C 14-2-14 Gemini surfactant ethylene-bis(tetradecyldimethylammonium chloride) and 238g pseudoboehmite (Al 2 o 3 Content 72%, mass percentage) and mix uniformly; then mix 387.5g phosphoric acid (85%, mass percentage) and 400g water and drop in the aforementioned emulsion, dropwise add and stir 4h; Then dropwise add templating agent di-n-propylamine 170.0g, stir 4h, then dropwise add 101g of silica sol (SiO 2 content 30%, mass percentage), stirred for 4 hours, loaded into a kettle, crystallized at 200°C for 48 hours, then centrifuged, washed, dried overnight at 120°C, and calcined at 550°C for 24 hours to obtain a multi-order porous SAPO-11 molecular sieve.

[0057] (2) Take by weighing 140g of the multi-stage porous SAPO-11 molecular sieve prepared in the present embodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com